Innovations in Plastic Bottle Shredder Technology

In today’s world, the need for sustainable development and resource reuse is becoming more and more urgent, especially in the field of plastic waste management. Plastic bottle shredder, as a key recycling machine in the treatment of waste PET bottles, is also evolving and innovating.

Shuliy Machinery is also keeping up with the times and has been researching and innovating the shredder machine, including the optimization of the internal structure, the improvement of the appearance, and the enhancement of the multi-functionality.

Advantages of plastic bottle shredder

Optimization of internal structure

Stronger cutting mechanisms: The new generation of plastic bottle shredder features stronger cutting mechanisms that can turn plastic into pieces more quickly and efficiently. These cutting mechanisms are made of advanced materials and designs for longer service life.

Aesthetic appearance

The appearance of plastic bottle shredders has been improved to meet the aesthetic requirements of modern factories and recycling sites. They usually have well-designed housings and are more compact overall. Shuliy Machinery also provides customized service, the machine color can be customized, we can print the customer’s logo on the body of the machine, and then it will be your unique machine.

Increased Versatility

Multiple Material Suitability: New technologies have made the plastic bottle shredder more flexible to handle multiple types of plastics including soft, hard, HDPE, PET, PP, PE and many more.

Shredding pelletizing line for plastic

Shredding is usually the first step in plastic recycling. We use plastic shredders for this task. After crushing, small pieces of waste plastics need to be further processed to make recycled plastic pellets in the complete plastic recycling pelletizing line. This process is usually done using a plastic pelletizer.

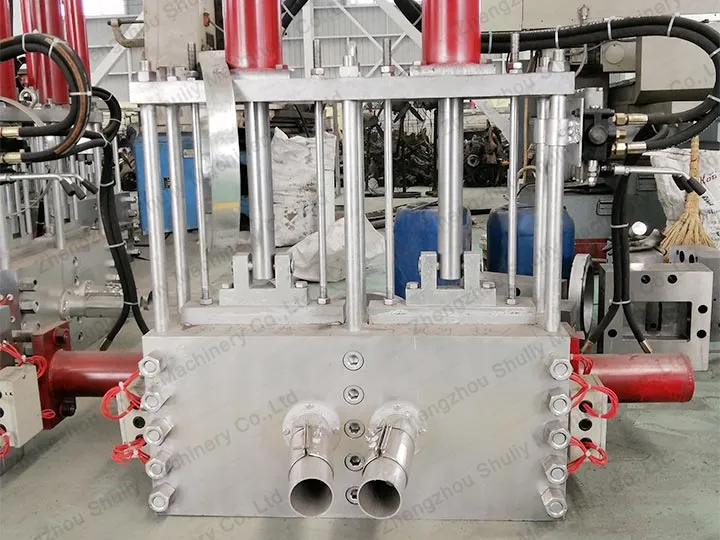

The plastic pelletizer machine will heat the crushed plastic, melt it, and then pass it through a mold to form pellets. These pellets can be customized to have different shapes, colors, and sizes. They can also resemble the original plastic and can be used again to make new plastic products.

To reduce labor costs and increase efficiency, plastic recycling lines are equipped with multiple conveyors.