HDPE and LDPE plastic recycling equipment: towards a sustainable future

With an increasing focus on sustainable development, plastic recycling has become a crucial part of the global agenda. Among these, the recycling of High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE) plastics has gained significant importance. These plastics are widely used in packaging, containers, bottles, bags, and more, making their recycling and reuse crucial for reducing the environmental impact of plastic waste. The article will introduce the two materials and plastic recycling equipment for them.

Characteristics of HDPE and LDPE Plastics

- HDPE is a high-density polyethylene commonly used for rigid plastic products like bottles, pipes, and plastic barrels. It is known for its resistance to chemical corrosion, which makes it a popular choice in packaging and container manufacturing.

- LDPE, on the other hand, is low-density polyethylene often found in flexible packaging, plastic bags, liquid containers, and similar products. Its flexibility and transparency make it a favored material.

HDPE and LDPE Plastic Recycling Equipment

Successful recycling of HDPE and LDPE plastics requires specific recycling equipment that can efficiently process, clean, and reprocess these plastics. Here are some common recycling equipment:

- Plastic Shredder: Plastic shredders are used to cut HDPE and LDPE plastic products into small granules. This is the first step in the recycling process, aimed at reducing the volume of the raw material for easier subsequent processing.

- Washing System: Post-consumer plastics often require cleaning to remove dirt, residues, and labels. The washing system includes a floatation separation tank, hot washing tank, and friction washer to ensure the resulting plastic is clean.

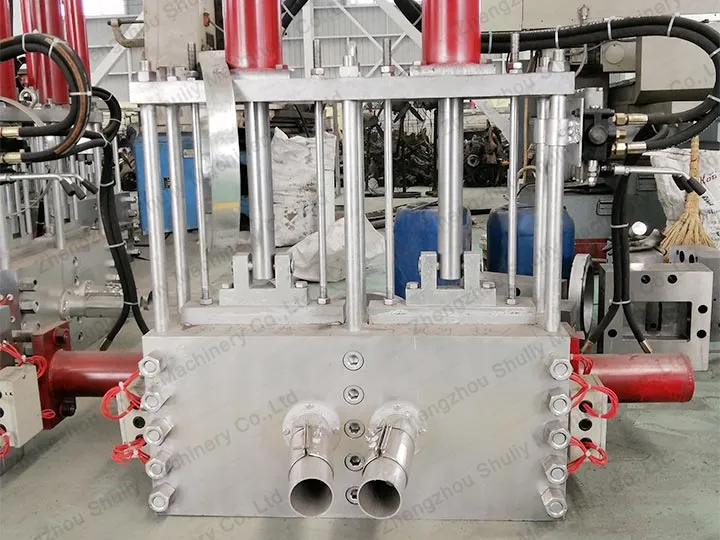

- Plastic Pelletizer: A pelletizer converts cleaned plastic into pellets by heating and compressing it, making it a viable raw material for new HDPE and LDPE products.

- Drying Machine: Drying machines are used to remove residual moisture, ensuring that the pellets meet quality standards.

- Conveyors and Storage: These devices handle and store the recycled plastic pellets, making them ready for production.

Importance of Sustainability

Recycling HDPE and LDPE plastics not only reduces the environmental impact of plastic waste but also minimizes the demand for virgin plastic resins. This helps conserve resources, reduce energy consumption, and supports a more sustainable mode of production.

Conclusion

HDPE and LDPE plastic recycling equipment mark a crucial step towards a sustainable future. Through efficient recycling and reutilization, we can decrease plastic waste, contribute to the environment, and provide the manufacturing industry with a sustainable source of raw materials. With the assistance of plastic recycling equipment, we can better manage these plastic materials and achieve a more sustainable plastic industry.