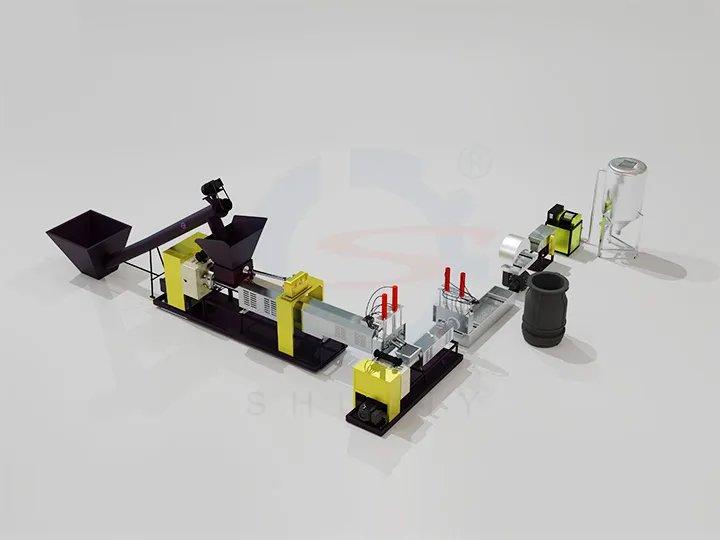

Plastic Recycle Machine for PP PE Film Bag Plastic Granulating Line

| Pelletizing Capacity | 100-500 kg/h |

| Application Materials | Woven bags, Soft irrigation pipe, Food wrapping, Waste garbage bags, Agriculture films, Plastic regrinds, bag film cut-offs, etc |

| Core Equipment | Plastic Crusher, Plastic Granulator, Washing System |

| Site Area Requirements for Regular Output | 300-500 Square Meter |

| Available Different Extruder Screw Model | 150mm, 180mm, 200mm, etc |

| Conveyor Qty | 3-4 |

| Warranty | 12 Months |

| Delivery Time | 20-25 days |

You can now ask our project managers for technical details

Our plastic recycle machines are desiged to process PE polyethylene (HDPE, LDPE, LLDPE) and PP polypropylene material, printed and non-printed, including plastic packaging bags, food wrappings, PP raffia bags, woven sacks, agriculture films, etc. This pelletizing line t is highly recommended for film producers of garbage bags, agricultural films, food packaging, shrink and stretch films, as well as producers in the woven industry of PP woven sacks, leno bags, jumbo bags, and soft irrigation pipes.

Introduction of Plastic Pelletizing Line

The main materials of plastic waste are PP, PE, LDPE, LLDPE, HDPE, PS, PVC, and so on. The entire pelletizing line includes crushing, cleaning, and granulation of waste plastics. The main plastic bag recycling machine has a plastic crushing and washing machine, rinsing tank, dehydrators, plastic granulators, cooling tanks, and pellet cutting machines. The plastic film recycling machine can be flexibly configured according to the raw materials and needs of customers.

Plastic Film Recycling Machine Video

The video shows the plastic film recycling machines stocked in our factory, our sales manager Sunny will introduce you to their appearance, working principle and machine output.

Four Advantages of Pelletizing System

Four major advantages of our plastic pelletizing system: good screw design, accurate feeding system, efficient temperature control system and certified reducer.

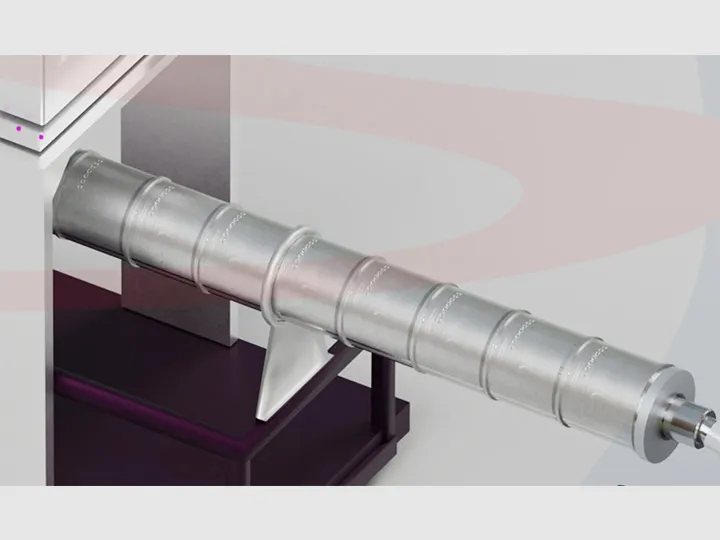

Scew Design

The design of the screw will directly determine the performance of the plastic in the hot melt and extrusion process, which ultimately affects the quality of the plastic granules.

Precise Auto Feeder

Shuliy’s automatic feeding hopper makes feeding easier by avoiding film material entanglement. Shuliy designed storage silos equipped with cameras to monitor the amount of material being fed by the conveyor belt, precisely controlling the steady feed and the working rate of the pelletizing machine.

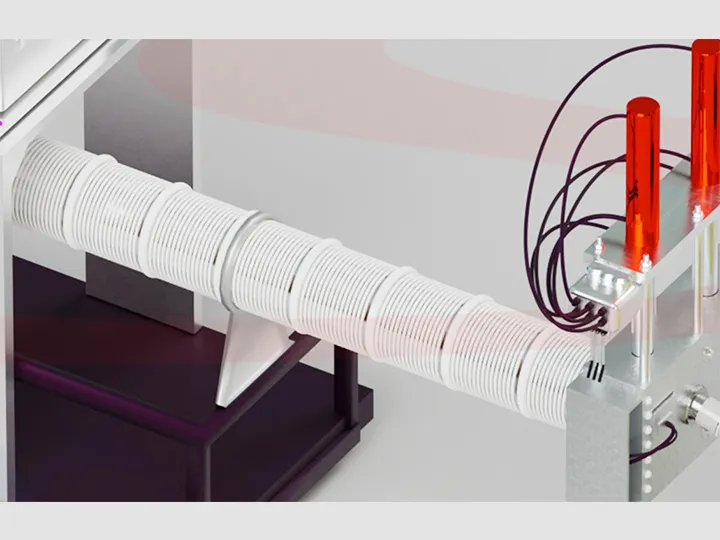

Two Alternative Heating-efficient Methods

Shuliy plastic film pelletizing line provides two different heating methods for your waste plastics: ceramic heating, and electromagnetic ring heating. Both of them have many advantages over traditional iron heating methods.

- Electromagnetic Heating Rings

The thermal efficiency of electromagnetic heating is extremely high, usually reaching more than 90%. Most of the electrical energy is directly converted into heat, accelerating the melting of plastic and reducing operating costs.

Electromagnetic heating systems can accurately control the heating temperature and can handle a wide range of plastics with different melting points, helping to improve the quality of plastic pellets.

- Ceramic Heating

Ceramic heating maintains a stable temperature, the temperature of the heating surface is uniform and avoids overheating, which makes it very energy efficient, safe and has a long life.

Certified Reducer

All Shuliy pelletizing machines are equipped with certified hardened gear reducers for high drive efficiency, low noise levels, long service life, and stable production.

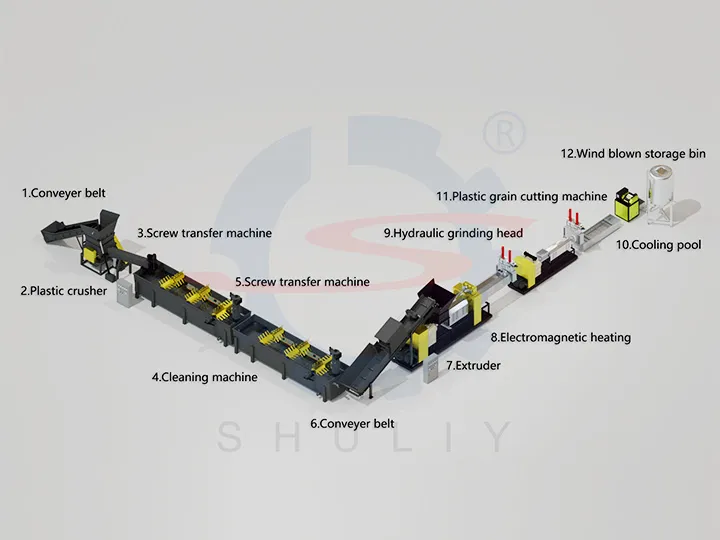

Complete Configuration of The Plastic Pelletizing System

Plastic Crushing Machine

To avoid tangling and clogging the rotary-type devices and conveyors, it is necessary to shred the long plastic films into small pieces with a crushing machine. The crusher is mainly suitable for plastic film crushing and cleaning.

It is characterized by directly cleaning the plastic fragments after crushing the plastic, with high efficiency. There is a rotating cutter inside the crusher, and the cutter is specially treated to crush the soft material into small pieces in a short time. Blades can be reground for durability.

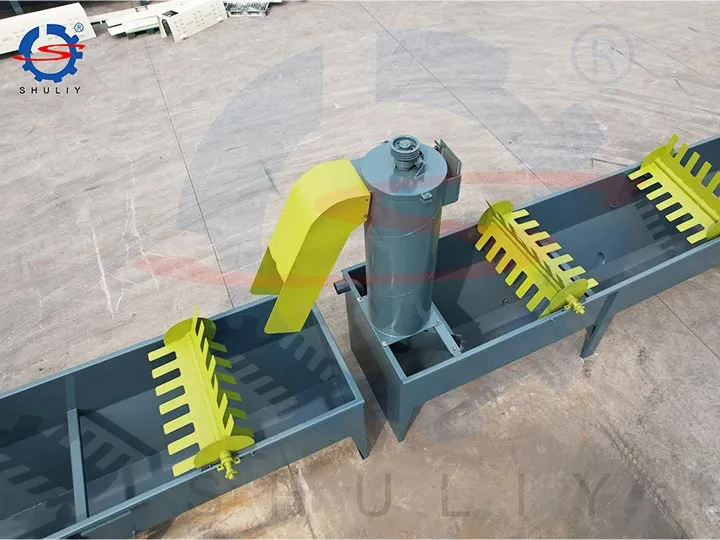

Washing System (Frictional Cleaning and Rinsing)

The washing system is mainly used to remove dirt from plastic waste to ensure the high quality of final granules. Through a frictional washer, the plastic films rub against each other at a high speed, getting rid of contamination like grease and dirt.

The plastic rinsing tank is made of stainless steel or iron plates. There are several toothed agitators installed in the upper part of the machine, which forces the plastic pieces forward. Generally, the length of the washing tank is 10 meters, it can be customized to 20m, or 30m with a larger recycling capacity.

Plastic Drying & Lifting Unit

After washing by the rinsing tank, a vertical dewatering machine plays an independent role in the film pelletizing line. It can dry the wet plastic films by strong centrifugal force, then lift them to the next pelleting process (repeated rinsing or pelletizing).

Inside the vertical dewatering machine is a spiral feeding device, which uses centrifugal force to throw out the moisture from the material during the spiral conveying process.

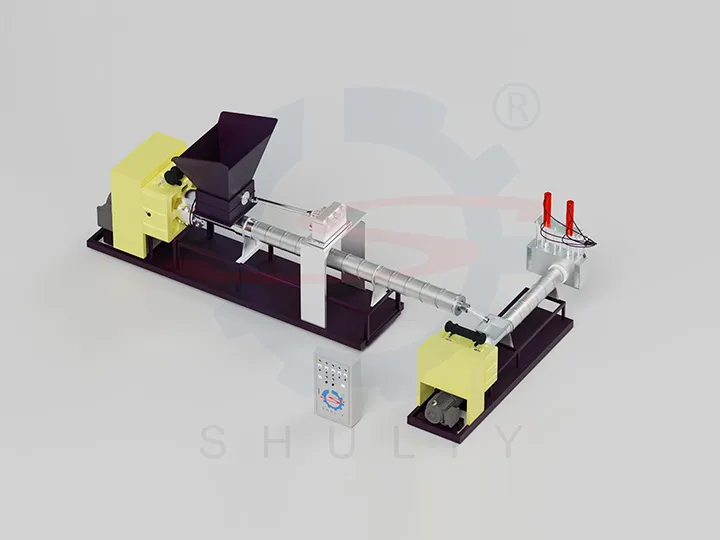

Plastic Melting & Extrusion Process

A plastic granulator is the most important plastic recycling machine in the plastic pelletizing line. It will realize granulation by melting plastic at a high temperature and then extruding it into long strands.

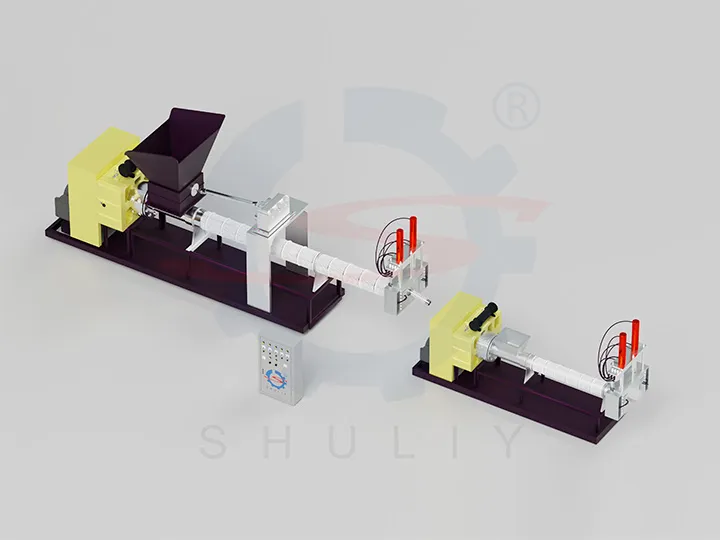

Generally speaking, the plastic will be melted and extruded by a two-stage pelletizing machine, However, a three-stage pelletizing extrusion machine is also available for the pelletizing line with a capacity of over 1 ton/h.

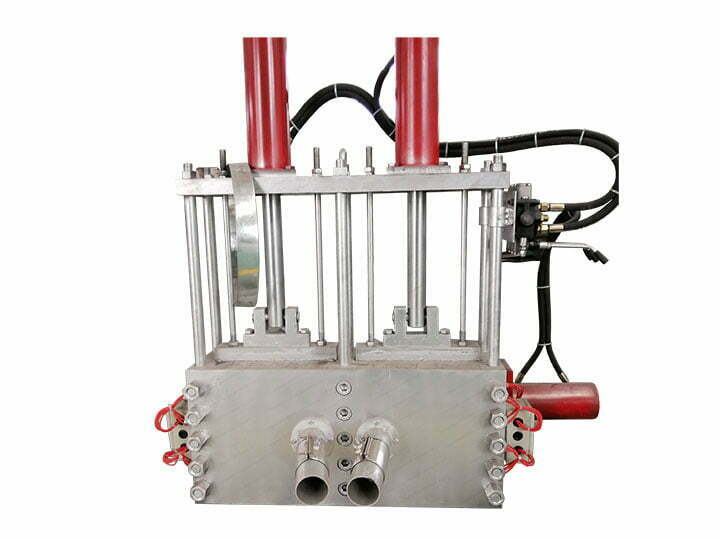

Pelletizing Die Head

Pelletizing dies are used in strand pelletizing systems for extruding plastic melt.

Shuliy offers 3 different types of pelletizing heads (including non-stop screen changers and motorized gear heads). They can meet the different requirements of the recycling plants in terms of plastic extrusion conditions.

Cooling Device

The cooling tank is made of stainless steel, which does not rust or corrode. It is mainly used to cool the soft ribbon material extruded from the plastic granulator to harden it.

Pellet Cutting Device

A plastic pellet cutting machine will cut plastic strips into plastic pellets, and the size of the pellets can be adjusted, which is an indispensable machine for the plastic granulating line. Shuliy provides a strand pelletizing system and water-ring pelletizing.

Silo Unit for Pellet Strorage

The plastic granules will be blown to the silo by the pipe.

This storage reduces dust accumulation and natural wastage, and better protects pellet quality and appearance.

Features of Plastic Recycle Machines

- The plastic recycling machine has a wide range of applications and is suitable for recycling and processing PP/PE waste plastic film, PP/PE plastic garbage mix, waste PP cement bags, space bags, household garbage plastic, waste agricultural greenhouse film, industrial packaging film, shopping bags, etc.

- The plastic recycle machines mainly consist of a crusher, a cleaning pool, a drying machine, a plastic pelletizer machine, and other equipment. The whole set of equipment is highly automated, and only one employee is needed to operate the whole process, saving labor costs.

- The plastic pelletizing line has low energy consumption and high production efficiency, and the recycled plastic pellets produced have smooth surfaces and uniform size, which can reach the market standard.

Applications of Plastic Bag Recycling Machine

Obtain Re-useable Plastic Pellets

Recycled plastic pellets are mainly differentiated into grades according to the different raw materials used and the characteristics of the processed plastic pellets, which are generally divided into first, second and third-grade materials.

- High quality of the first-grade material refers to the raw materials used for the quality is also better or not use plastic, they are common in post-industrial waste, such as HDPE/LDPE bag cut-offs, defective LDPE zipper bag production waste, edge trim, etc. These processed plastic pellets quality is nice and they can be directly sent to plastic product production.

- The secondary and third grade pellets are always from post-consumer waste. The recycle materials have been used. Shuliy Machinery is also designed to work with washed, post-consumer waste. The recycled pellets can be used again in the extrusion process. You can use 100% recycled pellets for plastic production (such as garbage bag, irrigation pipe production, etc), or as part of the mixture to reduce raw material costs in the production. The recycled pellets’ quality can also be improved by direct adding masterbatch and additives.

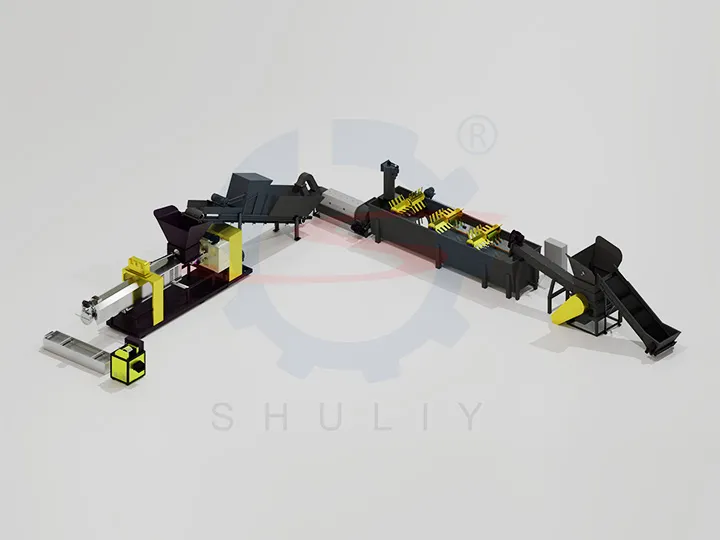

3D Video of Plastic Recycle Machine for Pelletizing

How to Make Plastic Pellets?

Parameter of Plastic Bag Recycling Machines

| NO. | Item | Technical data |

| 1 | Conveyor | Power:3kw Size: Length 5m Width 0.8m Capacity:1000-1200kg/h |

| 2 | PP PE crusher | Model:1000 Power:37kw+11kw Capacity:1000kg/h |

| 3 | Belt Conveyor | Power:1.5kw Size : (L) 4m* (W) 0.6mm Capacity:800-1200kg/h |

| 4 | Automatic Feeder | Power:3kw Capacity:800-1200kg/h |

| 5 | Main Plastic Granulator | Model: SL-220 Screw diameter: 220mm Screw length: L1.6m Motor:22+18.5kw |

| 6 | Vice Plastic Granulator | Model: SL-260 Screw diameter: 260mm Screw length:3.6m Motor: 110kw |

| 7 | Pellet Cutting Machine | Power:1.5kw Size:1000*1200*1100mm |

| 8 | Plastic Pellet Bagging Machine | Model:1000 Power:37kw+11kw Capacity :1000kg/h |

Plastic Granulator and Other Machine to Recycle Plastic in Our Plant

Machine to Recycle Plastic Shipped to Germany

Germany is one of the best countries in the world for waste sorting and recycling, with a recycling rate of about 65%. Also, we have successful cases with German customers. Encouraged by the national policy, our German customer decided to start a plastic recycling business last year, mainly recycling some waste plastic shopping bags. He looked online for manufacturers to buy machines and found us.

Our factory has produced and sold plastic bag recycling machines for more than ten years and has rich experience. After the sales manager understands the customer’s needs, he makes several different quotations. Facing the customer’s problem, we effectively solve it. Finally won the trust of the customer, and now the plastic granulating line has been shipped to Germany.

Global Cases of Plastic Pelletizing Lines Around the World

Shuliy plastic recycling machines are exported to more than 20 countries. They are used to recycle all kinds of plastic waste. Our customers have very good feedback about Shuliy plastic recycling machines and services. Please see the following successful cases.