Plastic Shredder Machine for Scrap Cutting Grinding

| Shredder Model | SL-600, SL-800, SL-1000 |

| Cutting Matertial | Pipes, milk bottles, auto waste, electric waste, film, bags, ropes, tubs, bubble wrap, containers, chemical drum, etc. |

| Grinding Capacity | 600-1000kg/hour |

| Material Type | PVC, HDPE, LDPE, LLDPE, ABS, PP |

| Number of Knives | 10pcs |

| Material of Knives | 60Si2Mn |

You can now ask our project managers for technical details

The plastic shredder machine is manufactured by Shuliy Machinery combined with many years of research experience, which is also called a plastic scrap cutting machine and plastic grinder. The shredder is used to grind barrels, baskets, milk bottles, toys. Plastic crushers have the characteristics of large crushing force, high output, and long service life. Shuliy plastic shredders have been exported to Germany, Ghana, Saudi Arabia and other countries, and have been well received by customers.

Plastic shredder recycling machine working video

Raw materials of plastic scrap cutting machine

The plastic cutting machine can crush all kinds of plastic scrap such as PVC pipes, HDPE oil drums, paint buckets, plastic household waste, injection molded items, electric waste, PP car bumpers, PP/PE shopping bags, HDPE agricultural films, used woven bags, cement bags, T-shirt bag cutoffs, jerry cans, etc. The cutting machine can also grind defective products and production waste for plastic manufacturers.

Working principle of plastic shredder

When the shredding machine is working, the motor drives the internal blades to rotate at high speed. The rotating blades will produce an angle with the fixed blades when they rotate, and the blades forming the angle will cut the materials, thus crushing large pieces. The crushed plastic pieces will fall to the discharge port through the screen filter. Plastic pieces that do not meet the size will continue to be crushed until the size meets.

Crusher machine advantages

- The crusher knife type is reasonably designed, which is conducive to the material being crushed evenly.

- The rotating knife frame and bearings of the crusher are made of high-quality steel, which is not easy to wear or break.

- The plastic crusher feed hopper is enlarged to effectively avoid material leakage during the crushing process.

- It should be noted that when dealing with soft materials, a fan should be added to the grinder machine. Shuliy provides an extra fan for the film grinder.

Parameters of plastic shredder machine

The following table shows the hot-sell models of the Shuliy plastic shredder machine.

| Shredder Model | SL-600 | SL-800 | SL-1000 |

| Motor power | 30 kw | 45 kw | 55 kw |

| Grinding capacity | 600-800kg/hour | 800-1000kg/h | 1000-1200kg/h |

| Material of shredding knives | 60Si2Mn | 60Si2Mn | 60Si2Mn |

| Number of shredding knives | 10pcs | 10pcs | 10pcs |

| Box width | 600cm | 800cm | 1000cm |

Using precautions of plastic scrap cutting machine

- Install the plastic scrap cutting machine in a ventilated position, so that the motor can fully dissipate heat and prolong its service life;

- After the scrap cutting machine has been used for some time, it is necessary to add lubricant to the bearing to ensure the normal operation of the machine.

- Regularly check the knives and screws inside the shredder, and check whether there is looseness between the blade and the knife holder to ensure the safety of the machine.

Welcome to field research our plastic scrap grinder

Shuliy welcomes our customers to visit our factory, showing them our real production and processing capabilities. We always believe that a site visit is important when buying a plastic grinder machine. Because some manufacturers will boast and exaggerate their company’s capabilities in all aspects, if the customer does not seriously go to the site visit to see the plant environment, the quality of the equipment, the grinder test run, they will not know whether the truth is the same as the plastic scrap grinder machine manufacturer promised or not.

Plastic recycling shredder machine successful projects

Shuliy Machinery sent plastic recycling shredder and other recycling equipment to Oman, if interested, you can read more info on this page: PET recycle machines shipped to Oman

Feel free to contact us to learn more about plastic scrap machine price.

Plastic shredder machine for recycling HDPE baskets shipped to Oman

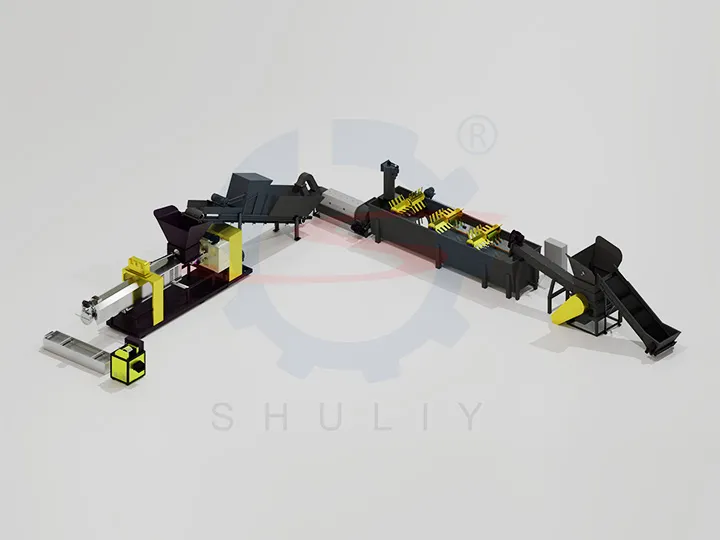

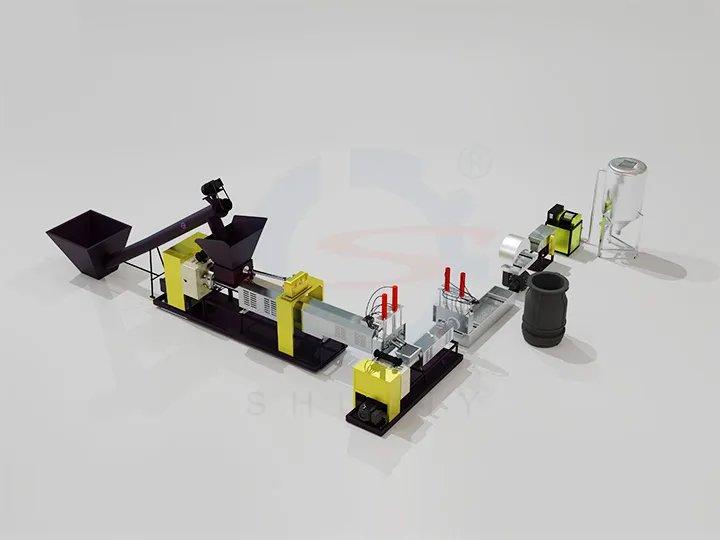

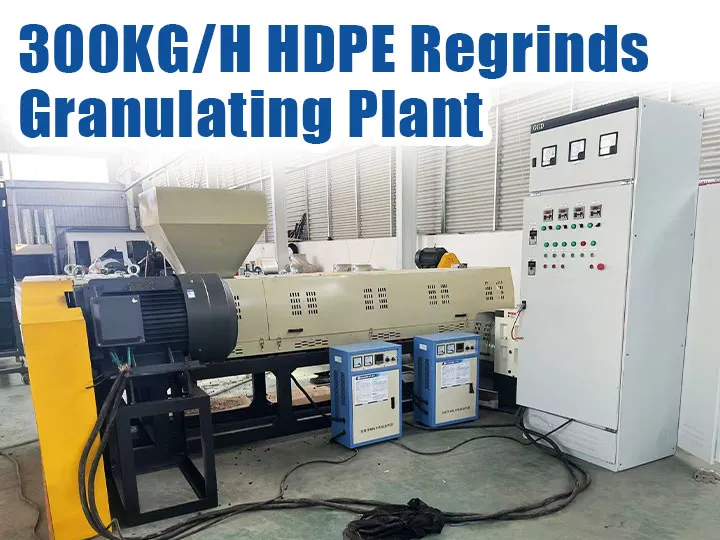

The video shows our HDPE scrap grinder in Oman, our clients purchased our plastic pelletizing line, including a shredder for grinding HDPE scrap, a pelletizer, a washing tank, and a dryer. More details and videos you can get by reading the case: HDPE plastic recycling line in Oman

Two PVC scrap grinders exported to Ghana

Our plastic crushers have been exported to Ghana. The Ghanaian customer has his own manufacturing company and now he wants to get into the plastic recycling business. He wanted to buy a few recycling machines to try out first. Therefore he found our sales manager Sunny on our website. After talking with the customer, he bought two PVC scrap grinders, model SL-600, with 22KW power and 600-800kg/h. If everything goes well with those grinders, he will buy the whole pelletizing line later.

Recommend machines

Plastic scrap cutting machines are usually used in plastic recycling plants, often paired with plastic pellet machines to form a complete plastic pelletizing line. Plastic pellets can be sold directly into recycled plastic products with high economic benefits.

If you are interested in the plastic recycling business, welcome to consult Shuliy Group or leave messages on our website. We will recommend the most fittable machines for you.