Plastic Granules Making Machine for PP LDPE HDPE Recycling

| Screw diameter | 105, 125, 135, 150, 180 mm |

| Recycle material | Defective blow-molded films/bag, injection molded material, plastic regrind, thermoformed packaging, automotive part, agriculture film, garbage bag |

| Application | Blow molding producer, injection molding manufacturer, plastic recycling center |

| Material type | PP, LDPE. LLDPE, HDPE, PVC, PC, PA, ABS |

| Pelletizer brand | Shuliy Machinery |

| Extruding Output | 100-500 KG/H |

You can now ask our project managers for technical details

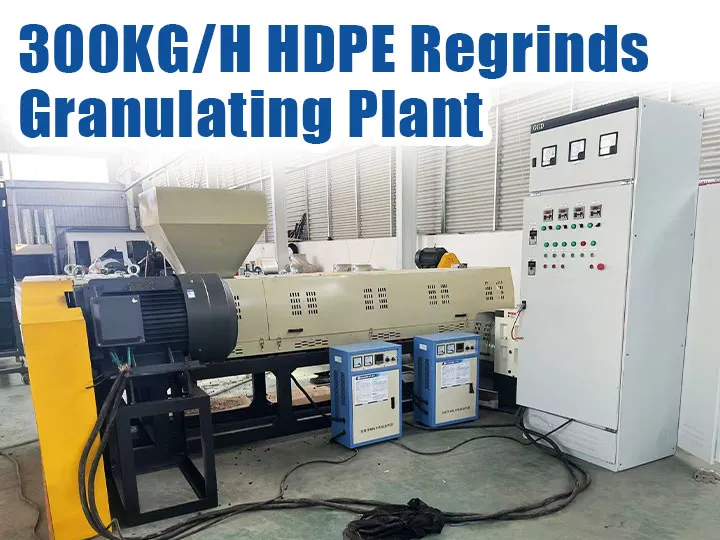

The plastic granules making machine, also known as a plastic pelletizer machine, is used to melt and extrude plastic waste into recycled plastic pellets with high profit. A twin-stage pelletizing system is the common model for plastic recycling plants, its capacity can reach 100-500kg/h, 2200-11000kg per day.

Meanwhile, single and three-stage pelletizing machines are also available in Shuliy Machinery, the specific extruding model is decided by your recycle materials, desired output, factory area, budget, etc.

Features of The Plastic Granules Making Machine

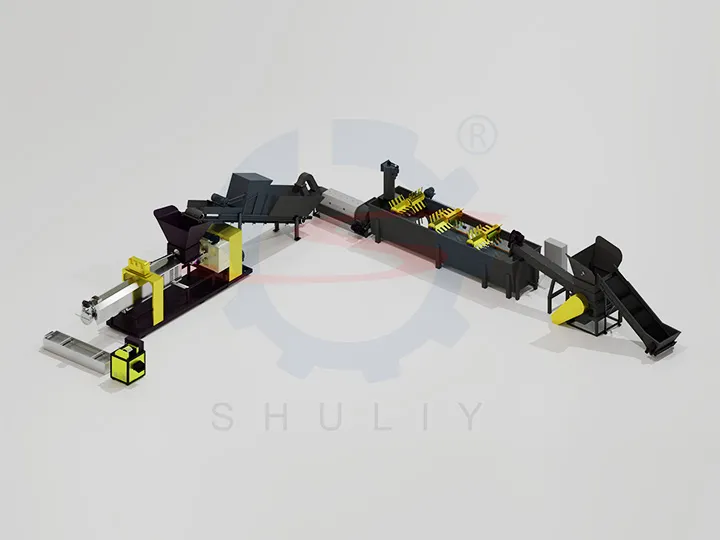

Multiple Configurations of Pelletizing System

We provide three different match styles for plastic granules making machines.

Firstly, a single-stage pelletizing system. It is a basic choice for recycling beginners. Its output and price are friendly for new entrepreneurs in the recycling area.

Secondly, a double-stage pelletizing system is the ideal one for most plastic recycling plants, no matter how big or small your plant is. The first stage we can call it a “mother pelletizer machine”, it can heat the recycle materials into plastic melt. But one plastic melting duration is short and coarse. It is not possible to melt the raw material evenly, especially for some plastics with high impurity content, high melting points or high output.

Therefore, we always recommend setting up a “baby pelletizing machine” after the first stage. A second stage pelletizer can help the recycler reduce the impurity and enhance plastic granule quality.

Finaly, a three-stage pelletizing system is also very popular in the recycling industry. It is designed for the extrusion pelletizing line of a capacity above 500kg/h, or the recycler has a very high standard for the final plastic granules. If interested, contact us to know more.

Alternate Plastic Melting Methods

Since the process of plastic pelletizing requires high temperatures, the cost of energy consumption in the plastic pelletizing industry also needs to be considered.

Nowadays, the plastic granules making machine on the market has formed a pattern of mainly electromagnetic heating, supplemented by iron heating coil heating and ceramic heating plastic pelletizing machines. The effect of electromagnetic heating is the best compared with the other two. The waste plastic granules making machine developed by Shuliy Machinery adopts the new technology of a high-frequency electromagnetic heater, which is energy efficient with fast heating speed and is safe and reliable.

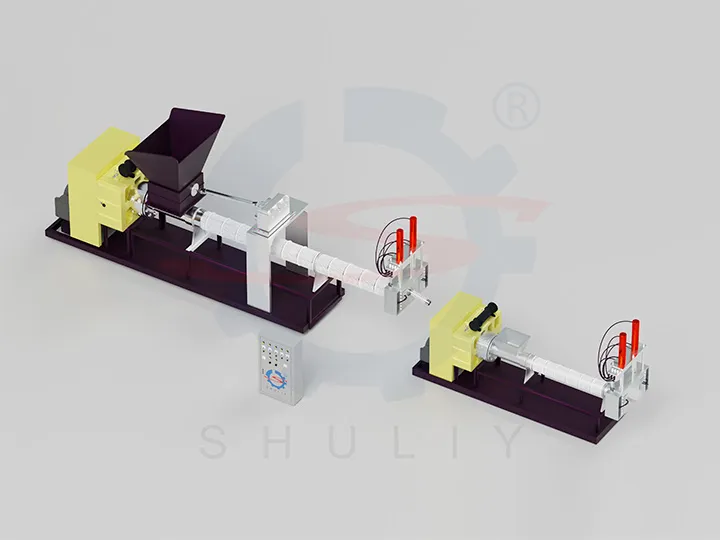

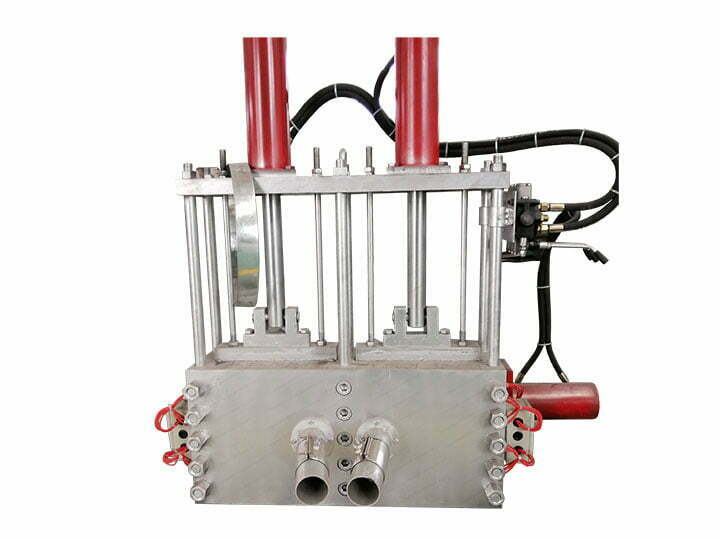

Efficient Pelletizing Die Heads

The die head of the plastic pelletizer machine has different types. They are electric gear die heads and hydraulic die heads. The electric gear die head needs to change the die screen inside manually, and it has a lower price which is more suitable for beginners with no experience.

The hydraulic model with double die heads is much more efficient. When one of the inside screens is dirty and needs to be changed, another pelletizing die will start to work continually. It saves time and human power, it also can meet the needs of bigger plastic extrusion capacity and extruding force.

Customers can choose the right die head for their recycling extruder machine according to their needs and budget.

If you are confused of choosing the proper die head, contact us now, our sales manager will recommend the right one for you according to your needs.

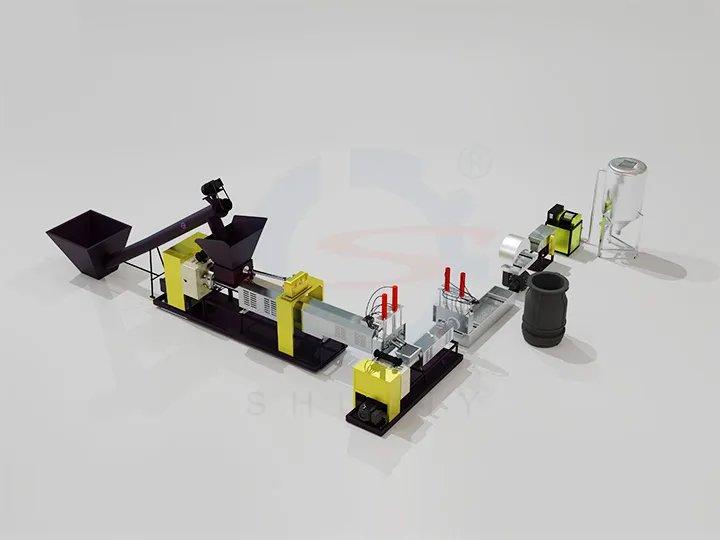

Pelletizer Cutting Type

- Strand pelletizing system

In strand pelletizing, the die head extrudes the plastic melt into strips, which are cooled and hardened in a water-cooling tank, and then cut by a plastic granules cutter.

- Water ring pelletizing system

The water ring pelleting system would be different. The plastic melt is extruded through the extruder die head and then cut directly by the rotating blades.

The plastic granules are immediately cooled in water, flushed out and then separated from the water on a vibrating table, and then dried in centrifugal dewatering equipment.

Working Video of PP Granules Machine

What Are the Suitable Recycling Materials?

The granules manufacturing machine adopts a special screw design and different configurations, which is suitable for producing PP, HDPE, LDPE, LLDPE, PS, PA, ABS, PVC, and other kinds of plastics for pelletizing.

Shuliy plastic granules making machines can process many raw materials, including injection molding regrind materials, thermoformed products, T-shirt bag cut-offs, edge trims, defective blown film products, waste industrial film, agricultural film, household shopping bags, pipes, woven bags, tubs, bottles, barrels, furniture, daily necessities, etc. The granules manufacturing machine can help us to reduce plastic pollution. It is the most versatile, widely used, and most popular plastic recycling extruding machine in the waste plastic recycling industry.

Final Granules of Pelletizer Machine

The end products are recycled granules, they play a vital role in the plastics recycling industry and their quality has a direct impact on the performance of downstream products and market applications.

Shuliy pelletizers produce plastic pellets that meet the following criteria.

- High purity: High-quality plastic recycling pellets have a high degree of purity, as Shuliy’s granules making equipment and its conveyor avoid the mixing of impurities such as metal, paper, oil, and other non-plastic materials during recycling, effectively increasing the purity of the product.

- High Uniformity: Shuliy granules making machine uses a uniquely designed three-stage screw that ensures stable temperatures during the melting, plasticizing and extruding stages. The complete melting and plasticizing to ensure uniformity of the final extruded granules’ quality and size.

- Color and gloss: Shuliy granules machine produces pellets with a consistent color and good gloss, and when used correctly, avoid air bubbles and black blemishes.

Structures of PP LDPE HDPE Granule Making Machine

This plastic granules making machine for recycling is mainly composed of a feeding port, screw press, press chamber, heating device, discharge port, mold head, reducer, and other parts. This plastic pelletizing machine is the main recycling machine in the plastic recycling line and can handle a variety of plastic materials.

Depending on the material to be pelletized, the diameter of the screw inside the pelletizing machine, the distance between the screw and the barrel wall, and the length of the screw are different. Therefore, one plastic pelletizer machine cannot process multiple materials at the same time.

Parameters of Plastic Pelletizer Machine for Sale

The model of the plastic pelletizer machine for sale is named after the screw diameter of the PP PE pelletizing machine, for example, the screw diameter of model 180 is 180mm. Among those following types, model 210 is the most popular in the market for its large output and proper price. If you are interested, welcome to consult.

| Type | 105 | 125 | 135 | 150 | 180 | 210 | 220 |

| Screw diameter | 105mm | 125mm | 135mm | 150mm | 180mm | 210mm | 220mm |

| Spindle speed | 50-70/min | 50-70/min | 40-50/min | 40-50/min | 40-50/min | 40-50/min | 40-50/min |

| Main motor power | 18.5kw | 30kw | 37kw | 37kw | 55kw | 75kw | 90kw |

| Reducer hard gear | 200 | 225 | 250 | 250 | 280 | 315 | 330 |

| Weight | 1.3T | 1.8T | 2T | 2T | 2.2T | 2.8T | 3.2T |

| Size | 2.4*0.7*0.7m | 2.6*0.7*0.7m | 2.8*0.7*0.7m | 3.0*0.7*0.8m | 3.2*0.7*0.8m | 3.5*1*1m | 3.8*1.2*1m |

| Output | 150KG/H | 180KG/H | 200KG/H | 300KG/H | 350KG/H | 380KG/H | 420KG/H |

Plastic Granules Making Machine Video

Precautions of Plastic Recycling Pelletizing Machine

Before using the pelletizer machine, there are some precautions you need to know. This can better ensure the overall performance of the machine and extend its service life.

- The operator must be careful not to put metal objects or hard objects into the plastic pelletizer machine, otherwise, it will be damaged. Do not place objects that may fall in around the feeding port.

- The operator must control the temperature during the dosing operation. Generally, the temperature of the main screw of the waste plastic pelletizing machine is set at about 200 degrees, and the temperature of the auxiliary screw is usually set at about 160 degrees.

Why Choose Shuliy Plastic Granules Making Machine?

- Shuliy Machinery has extensive experience in foreign trade and we provide our customers with all the granules machines to suit their needs as well as components, international logistics and plastic recycling solutions.

- Shuliy has more than 10 years of experience in plastic recycling machines manufacturing and guarantees the quality of our machines. We have invested heavily in research and development as well as in our production facilities, innovating and improving the performance of our recycling machines while maintaining their quality.

- Through years of hard work, we have trained many highly qualified employees. After receiving your inquiry, our sales staff will contact you and introduce you the machine details, including plastic granules manufacturing plant cost and plastic granules making machine price.

Global Case of Granules Manufacturing

PP Granules Making Machine

Recently, Shuliy Machinery has exported plastic recycling machines to Ghana. Our customer watched our machines’ videos and decided to purchase one PP granules making machine. After communicating with our sales manager Sunny, they decided to buy one granulator and one plastic granules cutter. Nowadays, our customer in Ghana has received our machines and begun their plastic granule production.

Yesterday they sent us a working video and expressed their gratitude to us, they said the granulating machine had a great capacity that could totally meet their demands. The following shows the packaged PP granules machine and a feedback video from them.

Other Global Cases of Plastic Granules Manufacturing Machine

Shuliy plastic granules manufacturing machines for PP HDPE LDPE PVC have been installed in more than 30 countries. These countries include Ghana, Germany, UAE, the UK, Kenya, Saudi Arabia, Ethiopia, etc. Here are some shipping and loading pictures for your reference. If you are interested, please feel free to contact us.

Read more:

- Opportunities for The Plastic Recycling Business in Ethiopia

- Saudi Arabian Client Chose Shuliy HDPE Granules Making Machine to Recycle Scrap

- Fast Delivery for PP granules machine delivered to Ethiopia

- Oman Customer Was Fascinated by Shuliy HDPE Regrind Granules Making Machine

The following video shows the global plastic granules manufacturing factories that used our plastic pelletizing machines. They have already received the equipment and completed the installation. They took the working video and expressed their satisfaction to us.

Choose One Complete Recycling Pelletizing Line

Shuliy Group provides a complete plastic recycling line for our customers. The plastic recycling line includes a belt conveyor, plastic crusher, plastic washing tank, plastic pelletizing machine, cooling tank and pellet cutter. We can also offer a customized pelletizing line according to customers’ demands.

Find Professional Plastic Pelletizer Manufacturers to Start Your Business

Shuliy Machinery is one of the most professional plastic pelletizer manufacturers in China, Whether you are a plastic recycling plant owner or a business starter, we can provide you with the best solution.

- Tell us what materials you are going to collect and recycle.

- Tell us what your ideal end product looks like.

- Decide the capacity of your plastic recycling plant.

- Contact Shuliy Group via the website form and our project manager will recommend the proper plastic granules manufacturing machine and customize recycling solutions for you.