Kunststoff-Recyclingmaschine für PP-PE-Folienbeutel Kunststoff-Granulierungslinie

| Pelletierkapazität | 100-500 kg/h |

| Bewerbungsunterlagen | Gewebte Beutel, weiche Bewässerungsrohre, Lebensmittelverpackungen, Abfallbeutel, Landwirtschaftsfolien, Kunststoffmahlgut, abgeschnittene Beutelfolien usw |

| Kernausrüstung | Kunststoffbrecher, Kunststoffgranulator, Waschsystem |

| Anforderungen an den Standortbereich für die reguläre Ausgabe | 300-500 Quadratmeter |

| Verschiedene Extruderschneckenmodelle erhältlich | 150 mm, 180 mm, 200 mm usw |

| Fördermenge | 3-4 |

| Garantie | 12 Monate |

| Lieferzeit | 20-25 Tage |

Sie können jetzt unsere Projektmanager nach technischen Details fragen

Unsere Kunststoff-Recyclingmaschinen sind für die Verarbeitung von bedrucktem und unbedrucktem PE-Polyethylen (HDPE, LDPE, LLDPE) und PP-Polypropylen ausgelegt, einschließlich Kunststoffverpackungsbeuteln, Lebensmittelverpackungen, PP-Bastbeuteln, gewebten Säcken, Agrarfolien usw. Diese Pelletierung line t empfiehlt sich besonders für Folienhersteller von Müllsäcken, Agrarfolien, Lebensmittelverpackungen, Schrumpf- und Stretchfolien sowie für Hersteller von PP-Gewebesäcken, Drehersäcken, Jumbo-Beuteln und weichen Bewässerungsrohren in der Webindustrie.

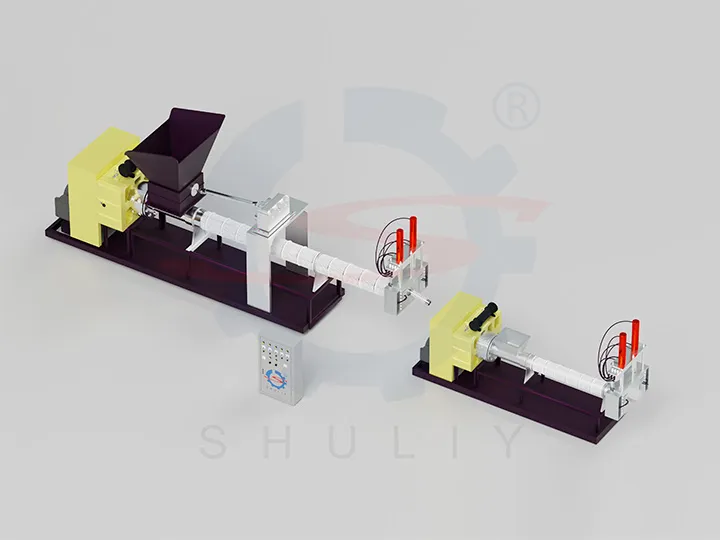

Einführung einer Kunststoffpelletierlinie

Die Hauptmaterialien von Kunststoffabfällen sind PP, PE, LDPE, LLDPE, HDPE, PS, PVC usw. Die gesamte Pelletierungslinie umfasst das Zerkleinern, Reinigen und Granulieren von Kunststoffabfällen. Die Hauptmaschine zum Recycling von Plastiktüten verfügt über eine Maschine zum Zerkleinern und Waschen von Kunststoffen, einen Spültank, Dörrgeräte, Kunststoffgranulatoren, Kühltanks und Pelletschneidemaschinen. Die Kunststofffolien-Recyclingmaschine kann je nach Rohstoff und Bedarf der Kunden flexibel konfiguriert werden.

Video zur Kunststofffolien-Recyclingmaschine

Das Video zeigt die in unserem Werk vorhandenen Kunststofffolien-Recyclingmaschinen. Unser Vertriebsleiter Sunny stellt Ihnen deren Aussehen, Funktionsprinzip und Maschinenleistung vor.

Vier Vorteile des Pelletiersystems

Vier Hauptvorteile unseres Kunststoffgranuliersystems: gutes Schneckendesign, genaues Zuführsystem, effizientes Temperaturkontrollsystem und zertifizierter Reduzierer.

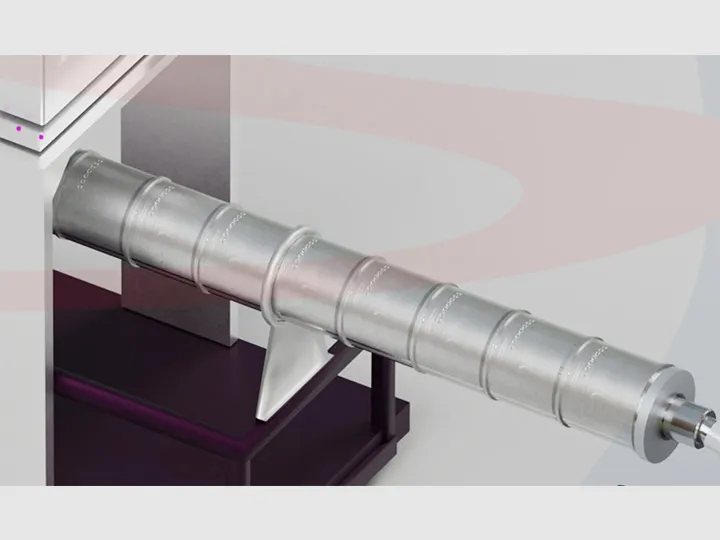

Scew-Design

Das Design der Schnecke bestimmt direkt die Leistung des Kunststoffs im Heißschmelz- und Extrusionsprozess, was sich letztendlich auf die Qualität des Kunststoffgranulats auswirkt.

Präzise automatische Zuführung

Der automatische Zufuhrtrichter von Shuliy erleichtert die Zufuhr, indem er verhindert, dass sich Filmmaterial verheddert. Shuliy entwarf Lagersilos, die mit Kameras ausgestattet waren, um die vom Förderband zugeführte Materialmenge zu überwachen und die gleichmäßige Zufuhr und die Arbeitsgeschwindigkeit der Pelletiermaschine präzise zu steuern.

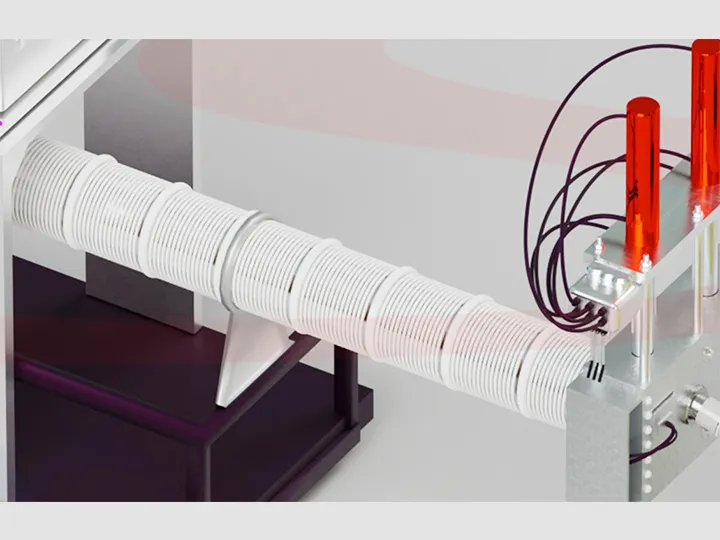

Zwei alternative heizeffiziente Methoden

Die Shuliy-Pelletieranlage für Kunststofffolien bietet zwei verschiedene Heizmethoden für Ihre Kunststoffabfälle: Keramikheizung und elektromagnetische Ringheizung. Beide haben viele Vorteile gegenüber herkömmlichen Eisenheizmethoden.

- Elektromagnetische Heizringe

Der thermische Wirkungsgrad der elektromagnetischen Erwärmung ist extrem hoch und erreicht normalerweise mehr als 90%. Der Großteil der elektrischen Energie wird direkt in Wärme umgewandelt, was das Schmelzen von Kunststoff beschleunigt und die Betriebskosten senkt.

Elektromagnetische Heizsysteme können die Heiztemperatur genau steuern und eine breite Palette von Kunststoffen mit unterschiedlichen Schmelzpunkten verarbeiten, was zur Verbesserung der Qualität von Kunststoffpellets beiträgt.

- Keramische Heizung

Die Keramikheizung sorgt für eine stabile Temperatur, die Temperatur der Heizfläche ist gleichmäßig und vermeidet Überhitzung, was sie sehr energieeffizient, sicher und langlebig macht.

Zertifizierter Reduzierer

Alle Shuliy-Pelletiermaschinen sind mit zertifizierten gehärteten Untersetzungsgetrieben für hohe Antriebseffizienz, niedrigen Geräuschpegel, lange Lebensdauer und stabile Produktion ausgestattet.

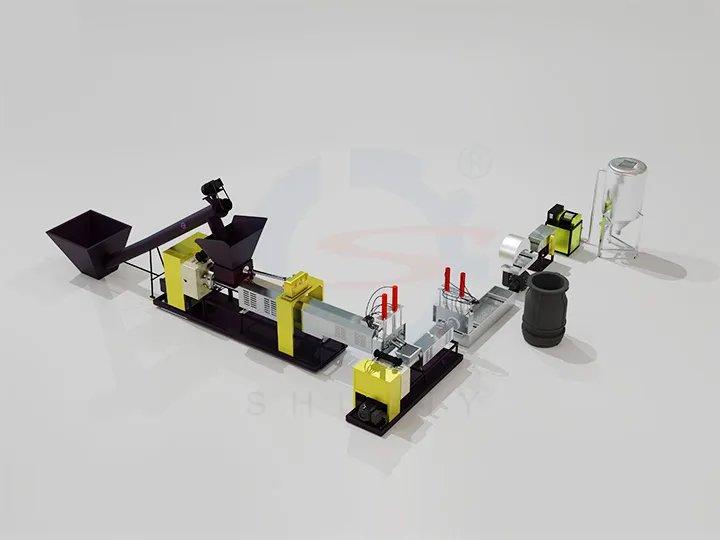

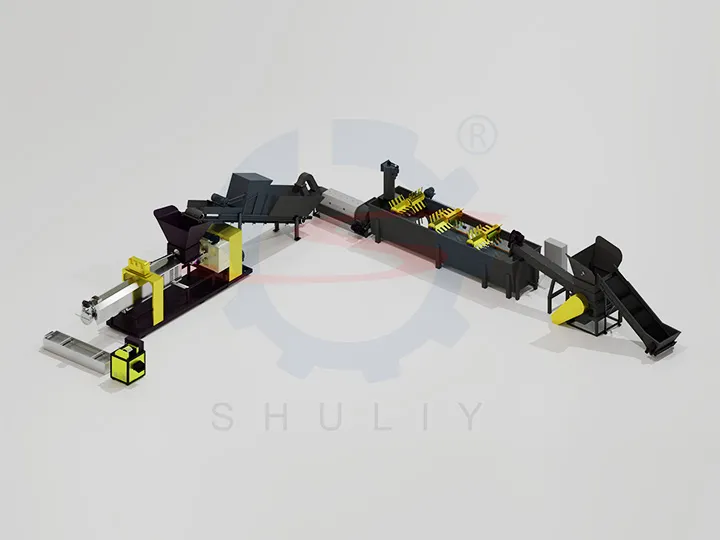

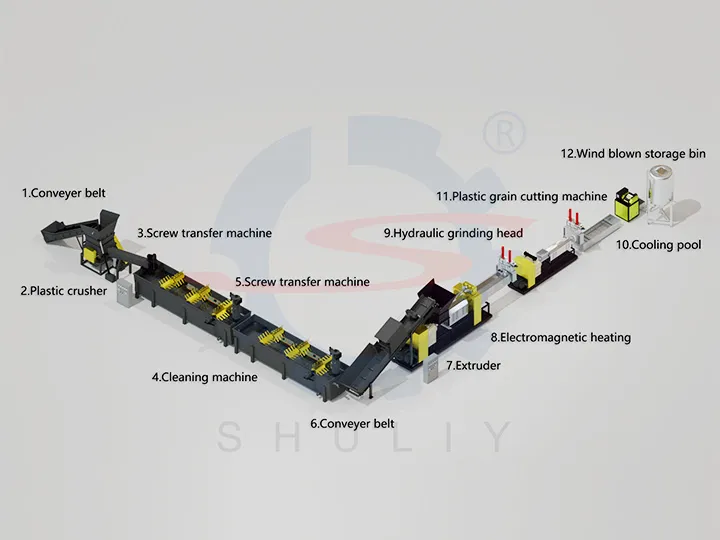

Vollständige Konfiguration des Kunststoffpelletiersystems

Kunststoff-Zerkleinerungsmaschine

Um ein Verheddern und Verstopfen der Rotationsgeräte und Förderer zu vermeiden, ist es notwendig, die langen Kunststofffolien mit einem Zerkleinerer in kleine Stücke zu zerkleinern Zerkleinerungsmaschine. Der Brecher eignet sich hauptsächlich zum Zerkleinern und Reinigen von Kunststofffolien.

Es zeichnet sich dadurch aus, dass die Kunststofffragmente direkt nach dem Zerkleinern des Kunststoffs mit hoher Effizienz gereinigt werden. Im Inneren des Brechers befindet sich ein rotierender Fräser. Der Fräser ist speziell behandelt, um das weiche Material in kurzer Zeit in kleine Stücke zu zerkleinern. Für eine längere Haltbarkeit können die Klingen nachgeschliffen werden.

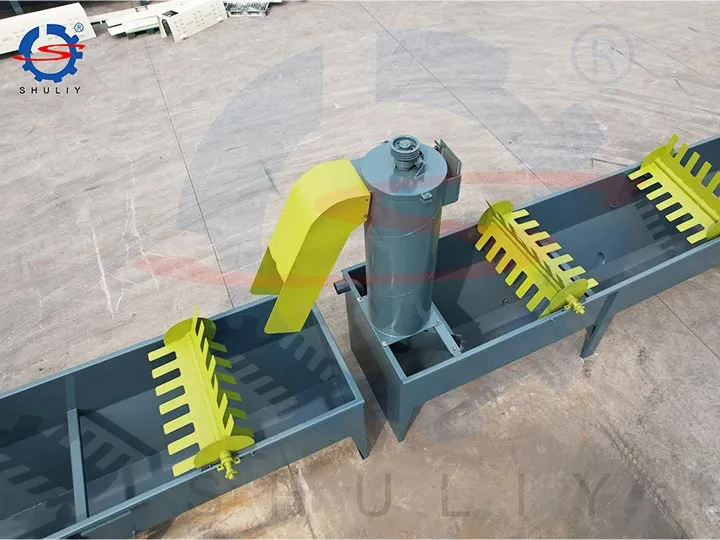

Waschsystem (Reibreinigung und Spülung)

Die Waschanlage dient hauptsächlich dazu, Schmutz aus Kunststoffabfällen zu entfernen, um die hohe Qualität des Endgranulats sicherzustellen. Durch eine Reibscheibe reiben die Kunststofffolien mit hoher Geschwindigkeit aneinander und entfernen so Verunreinigungen wie Fett und Schmutz.

Der Spülbehälter aus Kunststoff besteht aus Edelstahl- oder Eisenplatten. Im oberen Teil der Maschine sind mehrere Zahnrührwerke eingebaut, die die Kunststoffteile nach vorne treiben. Im Allgemeinen beträgt die Länge des Waschtanks 10 Meter, sie kann auf 20 m oder 30 m mit einer größeren Recyclingkapazität angepasst werden.

Kunststoff-Trocknungs- und Hebeanlage

Nach dem Waschen im Spültank a vertikale Entwässerungsmaschine spielt eine eigenständige Rolle in der Foliengranulierlinie. Es kann die nassen Kunststofffolien durch starke Zentrifugalkraft trocknen und sie dann zum nächsten Pelletiervorgang (wiederholtes Spülen oder Pelletieren) befördern.

Im Inneren der vertikalen Entwässerungsmaschine befindet sich eine Spiralfördervorrichtung, die während des Spiralfördervorgangs mithilfe der Zentrifugalkraft die Feuchtigkeit aus dem Material herausschleudert.

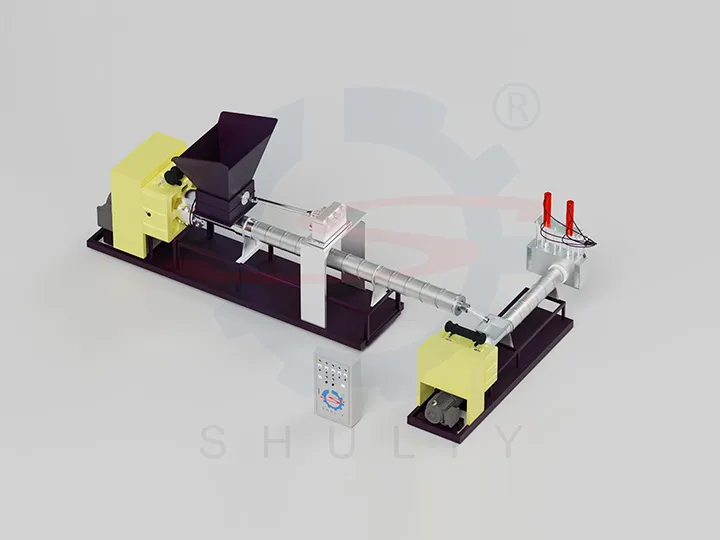

Kunststoffschmelz- und Extrusionsprozess

A Kunststoffgranulator ist die wichtigste Kunststoffrecyclingmaschine in der Kunststoffgranulierungslinie. Die Granulierung erfolgt durch das Schmelzen von Kunststoff bei hoher Temperatur und das anschließende Extrudieren in lange Stränge.

Im Allgemeinen wird der Kunststoff von einer zweistufigen Pelletiermaschine geschmolzen und extrudiert. Für die Pelletierlinie ist jedoch auch eine dreistufige Pelletier-Extrusionsmaschine mit einer Kapazität von über 1 Tonne/h erhältlich.

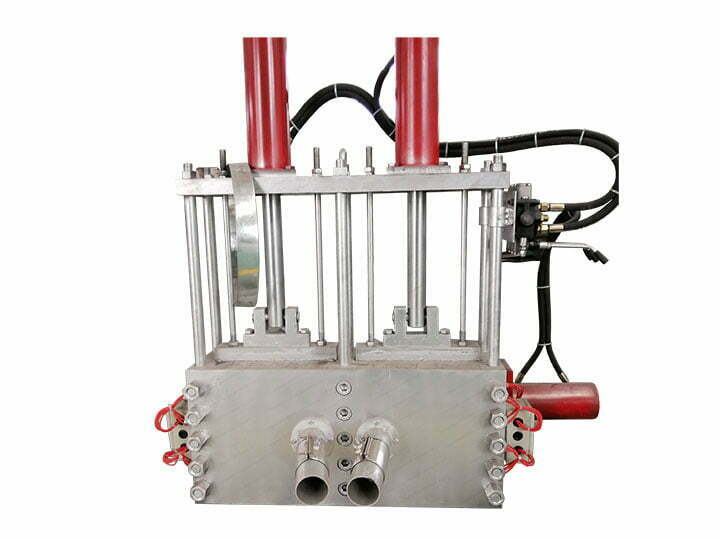

Pelletierdüsenkopf

Pelletierdüsen werden in Stranggranulieranlagen zum Extrudieren von Kunststoffschmelze eingesetzt.

Shuliy bietet 3 verschiedene Arten von Pelletierköpfen an (einschließlich Non-Stop-Siebwechsler und motorisierte Getriebeköpfe). Sie können den unterschiedlichen Anforderungen der Recyclinganlagen hinsichtlich der Kunststoffextrusionsbedingungen gerecht werden.

Kühlgerät

Der Kühltank besteht aus Edelstahl, der weder rostet noch korrodiert. Es wird hauptsächlich zum Kühlen des aus dem Kunststoffgranulator extrudierten weichen Bandmaterials verwendet, um es zu härten.

Pelletschneidegerät

A Kunststoff-Pellet-Schneidemaschine schneidet Kunststoffstreifen in Kunststoffpellets und die Größe der Pellets kann angepasst werden. Dies ist eine unverzichtbare Maschine für die Kunststoffgranulierlinie. Shuliy bietet ein Stranggranulierungssystem und eine Wasserringgranulierung an.

Siloeinheit zur Pelletlagerung

Das Kunststoffgranulat wird über das Rohr in das Silo geblasen.

Diese Lagerung reduziert Staubansammlungen und natürliche Verschwendung und schützt die Qualität und das Aussehen der Pellets besser.

Merkmale von Kunststoffrecyclingmaschinen

- Die Kunststoffrecyclingmaschine hat ein breites Anwendungsspektrum und eignet sich zum Recycling und zur Verarbeitung von PP/PE-Kunststofffolienabfällen, PP/PE-Kunststoffmüllmischungen, PP-Zementsäcken, Raumsäcken, Haushaltsmüllkunststoffen, landwirtschaftlichen Gewächshausfolienabfällen und Industrieverpackungen Film, Einkaufstüten usw.

- Die Kunststoffrecyclingmaschinen bestehen hauptsächlich aus einem Brecher, einem Reinigungsbecken, einer Trocknungsmaschine, einer Kunststoffgranuliermaschine und anderen Geräten. Die gesamte Ausrüstung ist hochgradig automatisiert und es ist nur ein Mitarbeiter erforderlich, um den gesamten Prozess durchzuführen, wodurch Arbeitskosten gespart werden.

- Die Kunststoffpelletierlinie zeichnet sich durch einen geringen Energieverbrauch und eine hohe Produktionseffizienz aus, und die produzierten recycelten Kunststoffpellets haben glatte Oberflächen und eine einheitliche Größe, die den Marktstandard erreichen können.

Anwendungen der Plastiktüten-Recyclingmaschine

Besorgen Sie sich wiederverwendbare Kunststoffpellets

Recycelte Kunststoffpellets werden hauptsächlich nach den verschiedenen verwendeten Rohstoffen und den Eigenschaften der verarbeiteten Kunststoffpellets in Qualitäten eingeteilt, die im Allgemeinen in Materialien erster, zweiter und dritter Qualität unterteilt werden.

- Die hohe Qualität des erstklassigen Materials bezieht sich auf die verwendeten Rohstoffe. Die Qualität ist ebenfalls besser oder es wird kein Kunststoff verwendet. Sie kommen häufig in postindustriellen Abfällen vor, wie z. B. HDPE/LDPE-Beutelabschnitte und fehlerhafte LDPE-Reißverschlussbeutel-Produktionsabfälle , Randbeschnitt usw. Die Qualität dieser verarbeiteten Kunststoffpellets ist gut und sie können direkt zur Kunststoffproduktproduktion weitergeleitet werden.

- Die Pellets der zweiten und dritten Klasse stammen immer aus Post-Consumer-Abfällen. Es wurden Recyclingmaterialien verwendet. Shuliy Machinery ist auch für die Verarbeitung von gewaschenem Post-Consumer-Abfall konzipiert. Die recycelten Pellets können im Extrusionsprozess erneut verwendet werden. Sie können recycelte 100%-Pellets für die Kunststoffproduktion (z. B. für die Herstellung von Müllsäcken, Bewässerungsrohren usw.) oder als Teil der Mischung verwenden, um die Rohstoffkosten bei der Produktion zu senken. Die Qualität der recycelten Pellets kann auch durch die direkte Zugabe von Masterbatch und Additiven verbessert werden.

3D-Video einer Kunststoffrecyclingmaschine zum Pelletieren

Wie stellt man Kunststoffpellets her?

Parameter von Plastiktüten-Recyclingmaschinen

| NEIN. | Artikel | Technische Daten |

| 1 | Förderer | Leistung: 3 kW Größe: Länge 5 m Breite 0,8 m Kapazität: 1000–1200 kg/h |

| 2 | PP-PE-Brecher | Modell: 1000 Leistung: 37 kW + 11 kW Kapazität: 1000 kg/h |

| 3 | Bandförderer | Leistung: 1,5 kW Größe: (L) 4 m * (B) 0,6 mm Kapazität: 800-1200 kg/h |

| 4 | Automatischer Futterspender | Leistung: 3 kW Kapazität: 800-1200 kg/h |

| 5 | Haupt-Kunststoffgranulator | Modell: SL-220 Schraubendurchmesser: 220 mm Schraubenlänge: L1,6 m Motor: 22+18,5 kW |

| 6 | Vice Kunststoffgranulator | Modell: SL-260 Schraubendurchmesser: 260 mm Schraubenlänge: 3,6 m Motor: 110 kW |

| 7 | Pelletschneidemaschine | Leistung: 1,5 kW Größe: 1000 * 1200 * 1100 mm |

| 8 | Kunststoff-Pellet-Verpackungsmaschine | Modell: 1000 Leistung: 37 kW + 11 kW Kapazität: 1000 kg/h |

Kunststoffgranulierer und andere Maschinen zum Recycling von Kunststoff in unserer Anlage

Maschine zum Recycling von Kunststoff nach Deutschland geliefert

Mit einer Recyclingquote von etwa 651 TP3T ist Deutschland eines der besten Länder der Welt für Abfallsortierung und -recycling. Das haben wir auch erfolgreiche Fälle mit deutschen Kunden. Ermutigt durch die nationale Politik beschloss unser deutscher Kunde letztes Jahr, ein Kunststoffrecyclingunternehmen zu gründen und hauptsächlich einige Einkaufstüten aus Plastikmüll zu recyceln. Er suchte online nach Herstellern, die Maschinen kaufen konnten, und fand uns.

Unsere Fabrik produziert und verkauft seit mehr als zehn Jahren Maschinen zum Recycling von Plastiktüten und verfügt über umfangreiche Erfahrung. Nachdem der Vertriebsleiter die Bedürfnisse des Kunden verstanden hat, erstellt er mehrere unterschiedliche Angebote. Wir stellen uns dem Problem des Kunden und lösen es effektiv. Endlich hat man das Vertrauen des Kunden gewonnen und nun wurde die Kunststoffgranulierlinie nach Deutschland verschifft.

Globale Fälle von Kunststoffpelletierlinien auf der ganzen Welt

Shuliy-Kunststoffrecyclingmaschinen werden in mehr als 20 Länder exportiert. Sie dienen der Wiederverwertung von Kunststoffabfällen aller Art. Unsere Kunden haben ein sehr gutes Feedback zu den Kunststoffrecyclingmaschinen und -dienstleistungen von Shuliy. Bitte sehen Sie sich die folgenden erfolgreichen Fälle an.