Working process of plastic recycling granulator

Plastic recycling granulators are a key tool in the recycling and reuse of plastics and are used to convert plastic waste into useful plastic pellets. These pellets can then be used to make new plastic products for sustainable recycling. However, operating these recycling machines requires care and expertise to ensure safe and efficient production. In this article, we will provide you with detailed steps on how to operate a plastic recycling granulator.

Total Time:

Preparation

Before starting the recycling granulator, make sure that the machine is on a level factory floor and not on a sloping area. This contributes to the stability and performance of the machine.

Prepare clean, decontaminated plastic scraps. These can be waste plastic products, plastic bottles, or other plastic materials. Ensure that the quality and processing capacity of the raw material is within the specifications of the machine.

Starting the plastic recycling granulator

Turn on the power and start the main motor in order to start the machine. It is necessary to start e.g. feed systems, heaters, etc. Ensure that the machine is able to start and run properly.

Feeding plastics into the inlet

In a complete plastic granules production line, it is the automatic feeder that drops the pre-treated plastic scrap into the inlet. It is important to note that no hard objects, such as metal, should fall into this step to avoid hurting the screw inside the machine. In addition, in this step, the input material should not exceed the granulator machine’s handling capacity, so as not to cause unnecessary load on the machine.

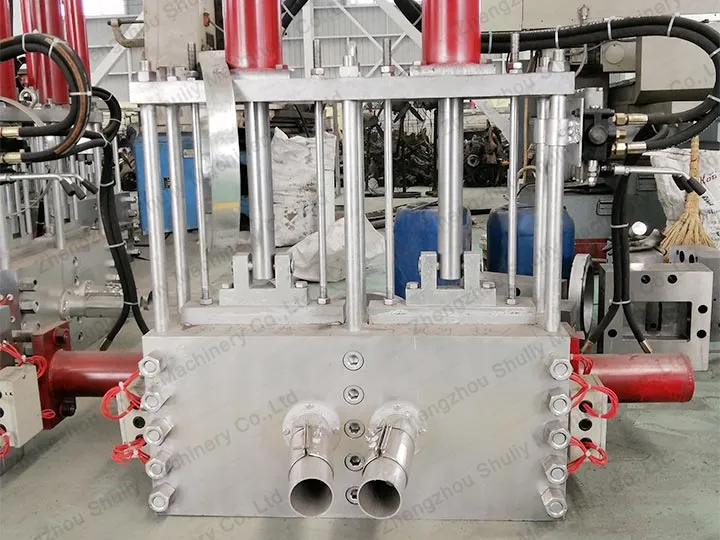

Melting and extruding

Depending on the melting point of the material, the plastic recycling granulator is set to the appropriate heating temperature. Normally, the machine will heat and melt the plastic and extrude it through the screw. Ensure that the temperature is set correctly to ensure quality melting and extrusion.

Cooling and cutting

The extruded plastic pellets are cut to the desired length by a cutting machine. The pellets are then cooled down and cured by a cooling system. This ensures that the quality and shape of the pellets are as expected.

Shuliy Machinery has helped many plastic recycling factories begin their businesses with plastic recycling granulators. The end plastic granules can meet the global market demands. If you are interested in plastic recycling machines, contact us now and we will provide you a customized recycling solution.