What is the waste HDPE recycling process?

HDPE is 100% recyclable, usually through a shredding, cleaning, and pelletizing process. HDPE is second only to PET in terms of recycling rates, and most recycling centers worldwide accept HDPE for recycling.

Introduction of HDPE plastic

HDPE This plastic is most often used in packaging, including milk bottles, laundry detergents, hair care products, and cleaning products. It is harder and more resistant to physical and chemical damage than many other plastics. After the HDPE recycling process, the recycled HDPE pellets are often reused in non-food containers and crates.

The HDPE recycling process

- Collection. Collected HDPE bottles and containers will be transported to the material recovery station for sorting.

- Sorting. HDPE containers are then sorted into two categories according to color: one is opaque or translucent, such as milk bottles and juice bottles. The other is colored bottles, such as laundry detergent, detergent, and flavor bottles.

- Crushing: Crushing is an important step of the HDPE recycling process. HDPE is crushed into plastic chips using professional plastic crushers to facilitate subsequent cleaning and granulation.

- HDPE cleaning system includes a floating and sorting machine and rinsing tank. The principle behind the use of flotation machines is that materials with a specific gravity greater than water will sink . PE has a specific gravity less than water, so when the material is messy, the plastic that floats on water is HDPE.

- Rinsing is an effective way to remove the debris attached to HDPE. We provide professional rinsing tanks, and the plastic pieces will become clean by repeated rinsing.

- Drying. The washed HDPE flakes need to be dried. Shuliy machinery offers two types of plastic dryers, both horizontal dryers and vertical dryers.

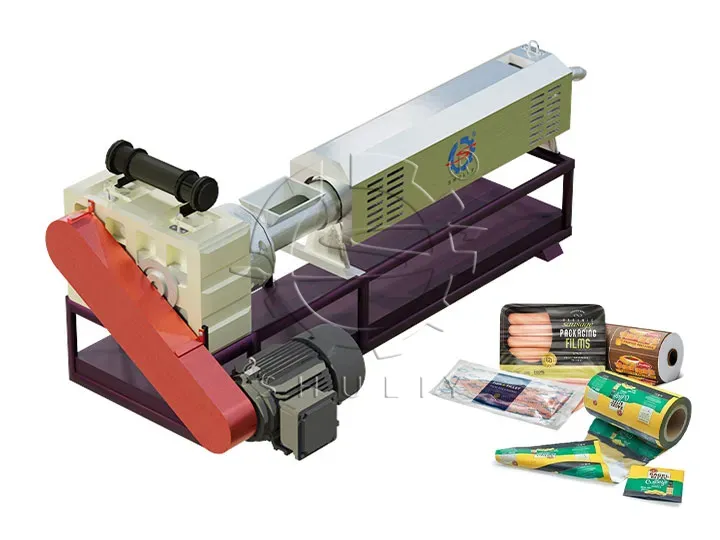

- Extrusion. It is the last step of the HDPE recycling process. The flakes are fed into a plastic granulator machine, which melts, mixes, and extrudes the flakes into pellets.

The final HDPE plastic pellets obtained can be used for various applications, such as office supplies, recycling bins, chemical detergent bottles, etc.