How to recycle cement bags?

Cement bags, an important packaging material for the construction industry, generate a large amount of waste yearly. To better combat this environmental problem, innovative recycling solutions have emerged. In this article, we will introduce how to recycle cement bags and waste cement bags.

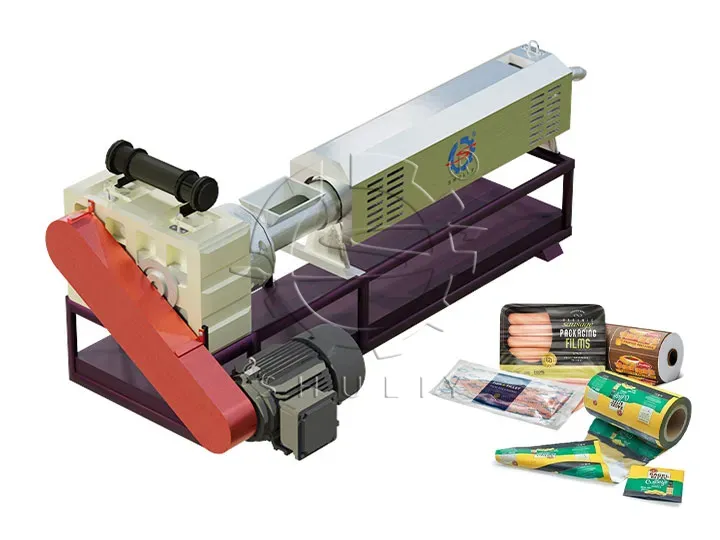

Application of plastic recycling machines

Using a professional plastic crusher is a common method to recycle cement bags.

- Crushing stage: Using a professional plastic crusher, the waste cement bags will be crushed quickly and efficiently, converting them into small particles for subsequent processing.

- Cleaning stage: The pulverized particles are washed through the cleaning tank to remove the dirt and residues attached to the cement bags and ensure the purity of the particles.

- Pelletizing process: Using a plastic granulator, the cleaned pellets are processed again to form uniform plastic pellets. These pellets can be used to make new plastic products and achieve waste reuse.

Other recycling methods

Manual dismantling: In areas with low labor costs, manual dismantling can be used to dismantle cement bags by hand to extract the recyclable parts.

Pyrolysis Recovery: Through high-temperature pyrolysis technology, the plastic components in cement bags are decomposed into oil and gas to realize the recovery of resources.

The recycling of cement bags becomes more efficient and environmentally friendly through the process of crushing, cleaning and pelletizing by plastic recycling machines. Meanwhile, other recycling methods provide diversified options.