What are the efficiency heating methods of pelletizing machine for plastic recycling?

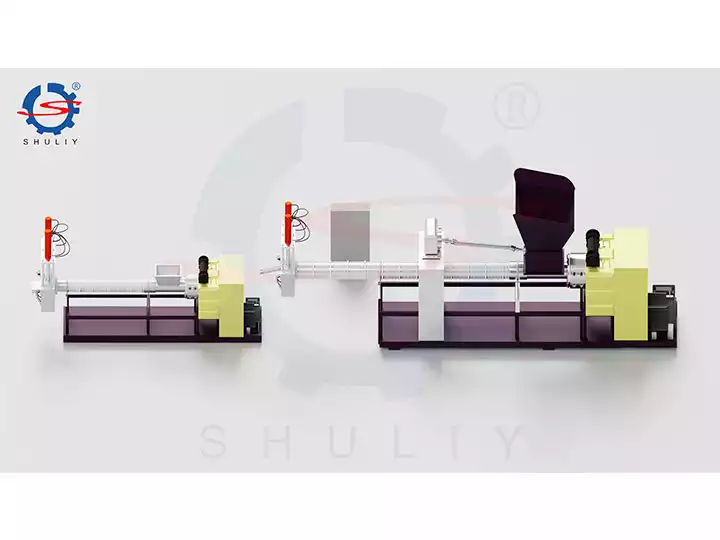

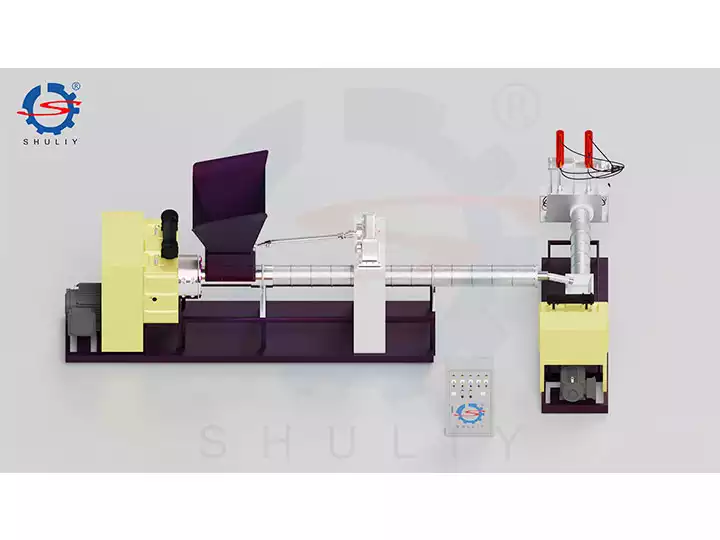

Electromagnetic heating and ceramic heating are two common and efficient heating methods used in pelletizing machine for plastic recycling, and they are key components in melting plastic.

Methods of pelletizing machine for plastic recycling

Electromagnetic heating

Ceramic heating

Differences between electromagnetic heating and ceramic heating

Principle:

- Electromagnetic heating: Electromagnetic heating utilizes the action of a high-frequency electromagnetic field to generate heat internally through the electric current generated by the conductive body. This method can quickly transfer energy to the conductive body so that it warms up.

- Ceramic Heating: Ceramic heating utilizes the principle of resistance heating, where an electric current generates heat in a resistive material. Ceramics are usually a material with a high electrical resistivity and can quickly generate heat when an electric current is passed through them.

Efficiency and speed:

- Electromagnetic heating: Electromagnetic heating is characterized by high efficiency and speed, capable of warming the heating body to the desired temperature in a short period of time, and is suitable for recycling plants that require high heating speed. We recommend the use of electromagnetic heating for pelletizing machine for plastic recycling when the customer’s output is more than 500Kg/h.

- Ceramic heating: ceramic heating may be slightly lagging in comparison, it takes some time to reach the set temperature, but its heating effect is more uniform.

Temperature control and stability:

- Electromagnetic heating: Electromagnetic heating usually has better temperature control and stability, and can accurately control the temperature of the heating body.

- Ceramic Heating: Ceramic heating may be limited in some cases by the properties of the material itself, and temperature control may be relatively simple.