The Ultimate Pelletizer Machine Maintenance Checklist to Extend Lifespan

A high-performance plastic granulator is a significant investment and the engine of your recycling operation. While robustly built, its longevity and consistent performance are not guaranteed by design alone—they are secured through diligent, routine care. Neglecting maintenance leads to unscheduled downtime, costly repairs, and reduced pellet quality.

This guide provides a practical and comprehensive pelletizer machine maintenance checklist. By integrating these tasks into your operational schedule, you can move from a reactive “fix-it-when-it-breaks” approach to a proactive strategy that maximizes your machine’s lifespan and protects your return on investment.

The Foundation: Daily Plastic Granulator Checklist

These simple tasks should be performed at the beginning and end of every shift. They take only minutes but are the first line of defense against common operational issues.

- Visual Inspection: Walk around the machine. Look for any loose bolts, damaged wiring, or signs of oil leaks around the gearbox and hydraulic station.

- Cleanliness: Remove any residual plastic, dust, or debris from the machine’s exterior, feeding hopper, and the area around the pelletizer. A clean machine is easier to inspect and runs cooler.

- Listen for Abnormal Noises: During startup and shutdown, listen for any unusual grinding, rattling, or high-pitched sounds. These are often the earliest indicators of a developing mechanical issue.

- Check Safety Guards: Ensure all safety guards and emergency stop buttons are in place and functioning correctly. Operational safety is paramount.

Digging Deeper: Weekly Pelletizer Maintenance Tasks

Once a week, dedicate time for these more thorough checks to address gradual wear and tear.

- Inspect V-Belts: Check the tension and condition of the V-belts on the motor and pellet cutter. A loose belt can slip and reduce performance, while an overly tight one can strain bearings.

- Check Electrical Connections: With the power safely locked out, open the main control cabinet and check that all electrical connections are secure. Vibrations can sometimes loosen terminals over time.

- Clean Cooling Systems: Inspect and clean the cooling fans on the main motor and the water channels in the cooling tank. Proper cooling is essential for both mechanical and electrical component longevity.

Proactive Care: Your Monthly Granulator Inspection & Lubrication Schedule

A proper monthly granulator inspection is a critical part of preventative maintenance that prevents major failures.

- Gearbox Oil Level Check: The gearbox is the heart of your machine’s power transmission. Visually inspect the oil level through the sight glass. It must not be below the center mark.

- Lubrication: Follow a strict plastic granulator lubrication schedule. Key pivot points and bearings may require greasing. Most importantly, plan your gearbox oil changes. Based on our operational guide, we recommend changing the gearbox oil (specifically, a high-quality N220 intermediate pressure gear oil or equivalent) after the first 300 hours of operation, and then every 3000 hours thereafter.

Focus on Core Components: How to Maintain a Plastic Granulator for Peak Performance

Understanding how to care for specific high-wear components is key to long-term reliability. This is where excellent pelletizer machine maintenance truly pays off.

Plastic Granulator Screw Maintenance: The Heart of Your Machine

The screw and barrel endure immense heat, pressure, and abrasion. Their condition directly impacts your output and pellet quality.

- Prevent Metal Contamination: The number one enemy of a screw is metal. Even a small bolt can cause catastrophic damage. This is why a magnetic iron remover on the feeding conveyor is not an option, but a necessity, especially for a plastic rigid recycling line.

- Understand Material Wear: Our screws are forged from hardened 38CrMoAl alloy steel for maximum durability, but they are not invincible. Abrasive materials like glass-filled plastics will cause faster wear. Knowing your material helps you anticipate maintenance needs.

- Proper Shutdown: Never stop the machine with a full barrel. Always run it until all material is purged. This prevents material from solidifying on the screw, which can cause extreme torque and damage on the next startup.

Pelletizer Gearbox Maintenance: The Powerhouse

Our pelletizer machines are equipped with a robust hard gear reducer designed for high torque. Proper care ensures it delivers that power for years.

- Use the Correct Oil: Do not substitute the recommended N220 gear oil with a lower-grade alternative. The correct viscosity and pressure additives are crucial for protecting the gears.

- Keep it Cool and Clean: Ensure the gearbox housing is free from heavy layers of dust, which can trap heat and degrade the oil faster.

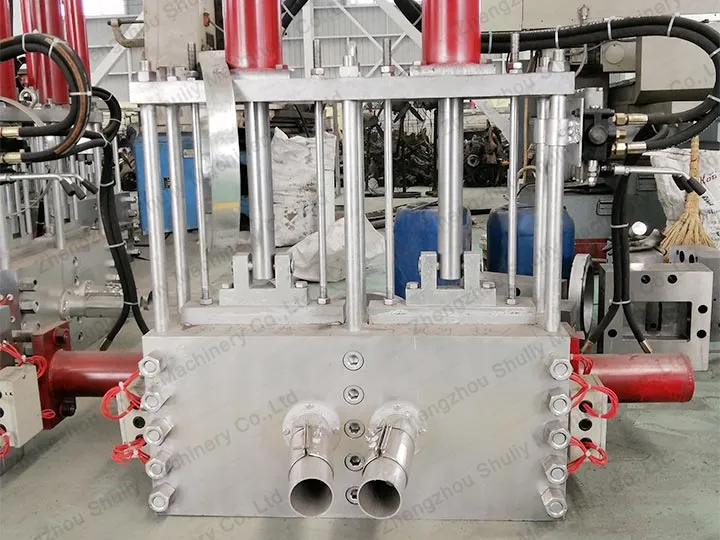

Granulator Screen Changer Maintenance: Ensuring Purity

For machines equipped with a hydraulic screen changer, especially those in a demanding plastic film recycling line, this component is vital for uptime.

- Check Hydraulic Hoses: Regularly inspect hydraulic lines for any signs of leaks, cracking, or abrasion.

- Clean the Breaker Plate: During screen changes, ensure the breaker plate (the perforated steel disc that supports the screen) is thoroughly cleaned of any carbonized material. Blocked holes reduce flow and increase pressure.

By following this checklist, you transform maintenance from a chore into a strategic advantage, ensuring your equipment remains a productive and profitable asset for years to come.