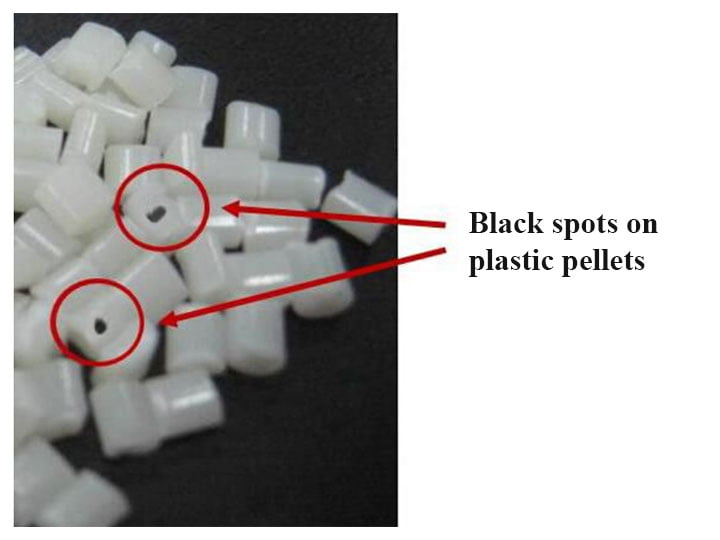

How to Solve The Problem of Black Spots on Plastic Pellets?

In the process of plastic granulation, it is a relatively common problem to encounter black spots on the pellets. Is it the problem of plastic pellet machine, the problem of raw materials, or other factors that lead to such a phenomenon? In fact, the problem of black spots in the granulation process is a common failure phenomenon, especially in the light-colored pellets more obvious. So how can we improve this problem?

These black spots are the residual plastic thermal deterioration of the plastic pellet machine after the carbide, in order to ensure the quality of plastic pellets, the staff should often clean the machine carbide.

Use harder plastic or its return material and white mineral oil for cleaning, and the temperature should be appropriately increased by 10~15°C. At this time, the plasticizing ability of the small extruder should be considered. For large and medium-sized extruders that can plasticize ultra-high molecular weight plastics, they can be cleaned with ultra-high molecular weight plastics or their return materials and white mineral oil. Because the hardness of ultra-high molecular weight plastics is better, and when the temperature is high, the cleaning object will be softened, so that it becomes easy to fall off, which is beneficial to the carbides being carried out by the plastic melt.

During the cleaning process, the speed of the plastic pellet machine can be repeatedly switched between low speed and high speed. If there is still a spare motor load, you can repeatedly stop and restart the extruder several times during the operation, which can improve the cleaning effect. When the carbide in the plastic melt is obviously reduced, gradually adjust to the appropriate temperature, then the normal production.