Three Different Die Heads of PP PE Granulating Machine

For PP PE granulating machine, Shuliy Group provides three different die heads, including an electric gear die head, an automatic slag filter, and a hydraulic die head. Customers can choose the proper die head depending on their requirements and budget.

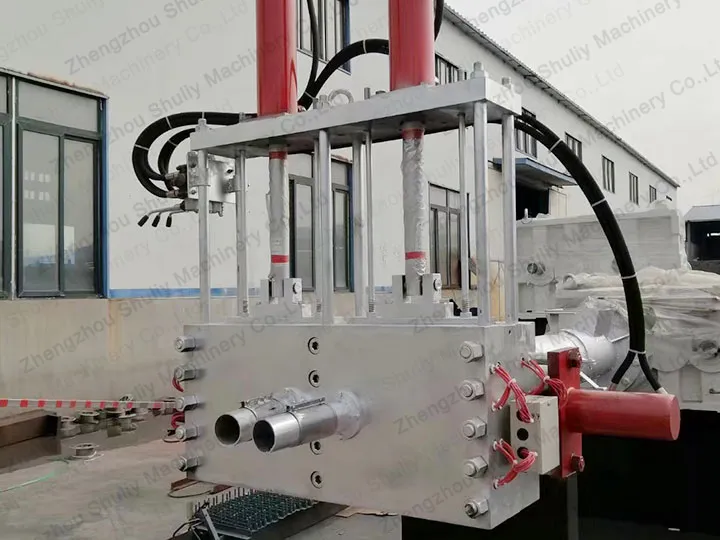

Type 1: Hydraulic die head

This hydraulic die head is the most popular one when customer purchase a PP PE granulating machine. The hydraulic die head is driven by hydraulic system, which has high production efficiency. Its non-stop screen-changing function makes it possible to change screens without stopping the machine, saving production time and increasing production efficiency. It is more efficient than traditional manual or semi-automatic die heads.

Type 2: Electric gear die head

Electric gear die head is a common type of PE granulating machine die head, electric gear die head is easy to use and simple to operate. It is easy to use and simple to operate. Adjustment of the speed and torque of the gear drive can be realized by simply adjusting the speed and torque of the gear drive through the control panel or buttons.

In addition, for areas where energy is scarce, the electric gear die head is more energy efficient and environmentally friendly than the traditional hydraulic die head, as it does not have the operating and maintenance costs of a hydraulic system.

Type 3: Automatic slag filter

The automatic slag filter die head of the PP PE granulating machine is a little bit more expensive and can be chosen for high budgets or for customers who have higher requirements for plastic pelletizing line.

The automatic slag filter die head is designed with an internal screen or filter that effectively filters out impurities and contaminants from the pelletizing process. This design allows the screen inside the die head to be automatically cleaned or periodically washed, making it easy to maintain and keep the die head running properly.

Moreover, the automatic slag filtering die head effectively removes impurities and contaminants from the pellets, resulting in a purer and more consistent quality of the plastic pellets produced. High-quality pellets help to increase the value and market competitiveness of recycled plastics.