Plastic Washing Line Exported to Chad – Soft PP/PE Film & Woven Bag Recycling Solution

In June 2024, we welcomed a customer from Chad, Mr. Abakar Ousman Gombo, who flew to China to personally visit our factory and inspect the operation of our plastic washing line. As a local entrepreneur planning to expand into the plastic recycling business, he sought a reliable and efficient solution to process large volumes of soft plastic waste, including PP woven bags and PE film scraps.

He had already collected a significant amount of used agricultural film, packaging film, and old woven sacks, but lacked the machinery to properly clean, crush, and dry the materials before pelletizing.

What Plastic Materials Will Be Recycled?

The raw materials for this project include:

- PP woven bags from fertilizer and grain packaging

- PE film rolls from agricultural mulch and general packaging

- Dirty soft film scraps collected from urban and industrial waste streams

These soft plastics are lightweight, bulky, and often contaminated with dust or organic matter, which makes manual cleaning inefficient and costly.

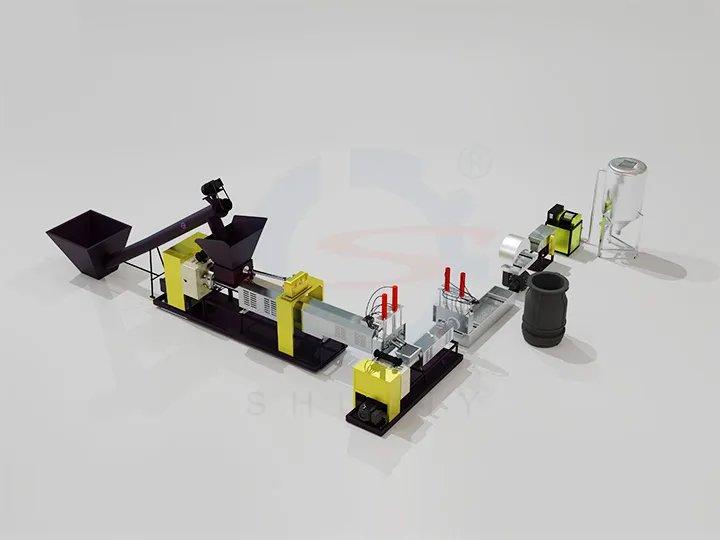

Customized PE Film Washing Line Solution

To meet the specific needs of the Chad market, we supplied a complete plastic film washing line with the following components:

- Plastic Crusher (SL-800) – Breaks soft film and bags into flakes

- Friction Washer – Removes dirt, labels, and surface contaminants

- Floating Washing Tank – Separates heavier materials and floats soft plastics

- Dewatering Machine – Removes moisture from cleaned film flakes

- Screw Conveyor – Transfers materials between washing stages

- Control Cabinet – Simplifies operation and ensures safe voltage compatibility

This PE film recycling line is designed to process 200–300 kg/h of soft plastic waste, offering a compact layout ideal for medium-sized recycling plants in Africa.