Affordable plastic recycling machine for sale: Help you start your business

In many countries due to the abundant resources of waste plastics, recycling is cheap, and is a national support project, many people want to start doing plastic recycling business, and open plastic recycling plants.

Our plastic recycling machine for sale has been exported to more than 20 countries such as Germany, Nigeria, Mozambique, Ethiopia, Malaysia, etc. It has helped many first-time plastic recycling business people to set up recycling plants. Now those plastic recyclers have gotten their profits by recycling plastic and sell plastic granules.

Plastic recycling machine for sale for starters

Shredding machines

Generally speaking, plastic shredder machines are the important machines of the plastic recycling machine for sale, they are also the first step of the official recycling process.

Plastic shredders are different according to your raw materials. We have professional shredders for PP LDPE, HDPE, PS, PET and so on. Welcome to consult!

Washing and drying systems

After the plastic waste is crushed into smaller pieces, the The plastic fragments need to be thoroughly cleaned with a washing system. Usually, hot water and detergent are used to remove dirt, grease and residue. Washing machines are usually equipped with agitators and spray systems to ensure uniform washing.

Rinsing and Dewatering: After washing, plastic chips may need to be rinsed by rinsing tanks to ensure complete removal of detergent residue. Then the plastics will be removed excess water through centrifugal dewatering machines. Drying is very important as wet plastic can negatively affect subsequent processing steps. Dryers are often used to remove residual moisture.

Pelletizing technology

Pelletizing systems and machines for plastics recycling are a core component of converting cleaned waste plastics into recycled plastic pellets. This includes key elements such as extruders, die heads, cooling and cutting systems, and vibratory screening equipment.

The working principle involves heating, extruding, cooling, cutting, screening and packaging the waste plastic to produce a final output of high quality recycled plastic pellets that can be used to manufacture new plastic products or sold directly.

Selecting the right plastic pelletizer model and configuration for the needs is critical to ensure the product meets market standards and customer requirements.

How can we assist you?

- Customized solutions for your recycling business

- Comprehensive after-sales service

- Reliable machine quality

- Dependable International Transportation

Contact us now!

Plastic recycling machine costs range from a few thousand dollars to tens of thousands of dollars, with the exact plastic recycling price varying with your production and machine configuration.

Our project manager will match your specific needs with the most suitable recycling machines, designing the drawings of the recycling plant, and all specific prices will be explained in detail. Contact us now.

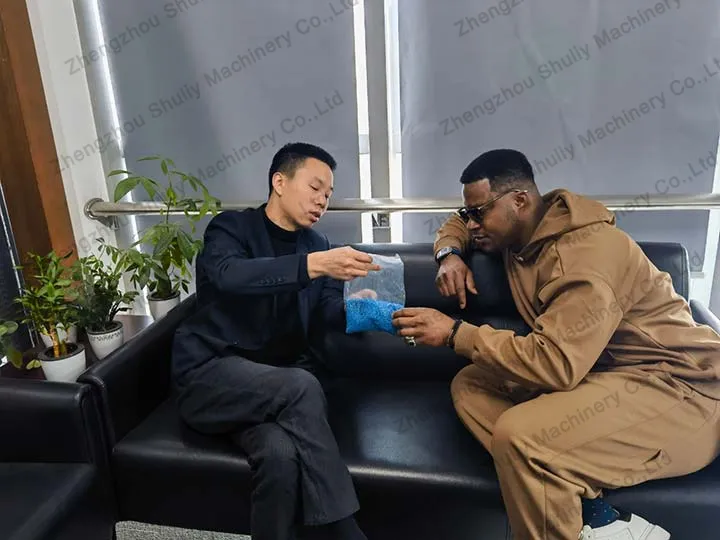

Customer from Togo visited our plastic recycling machines factory and order an recycling line for PP raffia bags pelletizing.

Customer from Poland visited the Shuliy factory and was very satisfied with our recycling machines for sale. We are looking forward the cooperation in the near future.

Client from Côte d’Ivoire visited our company and is interested in investing plastic granules production business.