How Can HDPE Recycling Enhance Circular Economy?

HDPE recycling fully supports the development of a circular economy by reducing resource consumption, lowering production costs, minimizing waste and environmental pollution, promoting sustainable development, and stimulating innovation and employment opportunities. This recycling practice not only brings economic benefits to companies but also pushes the plastics industry in a more environmentally friendly and sustainable direction.

Below is a comprehensive overview of everything you should know about HDPE.

What Is HDPE?

HDPE (High-Density Polyethylene) is a common plastic material with high strength, chemical stability, weather resistance and excellent mechanical properties, widely used in packaging materials, piping systems, construction materials, toys and agriculture.

HDPE Recycling Solution

HDPE plastic bags recycling. The common HDPE bags include grocery bags, trash bags, food storage bags, ice bags, merchandise bags, mailing bags, industrial bags, cement bags, etc.

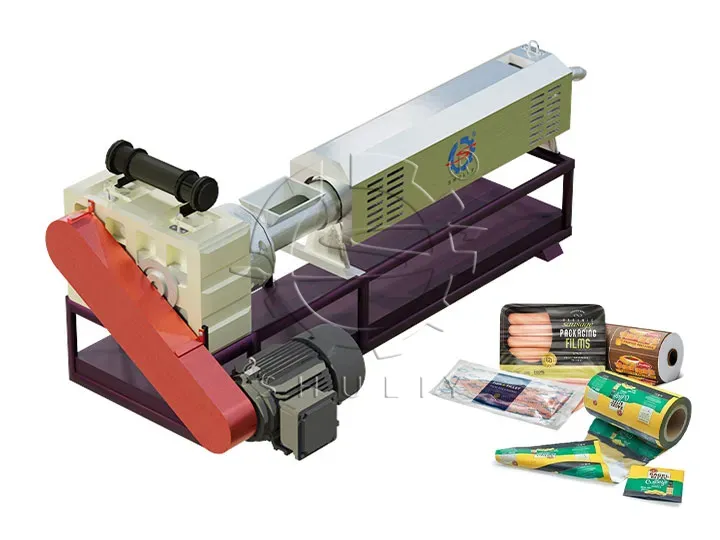

For clean bag trimmings generally do not need to be cleaned, crushed directly into the pelletizing machine, Shuliy HDPE pelletizing machine recycling capacity is 100-500kg/h. For post-consumer plastic bag scraps, crushed need to be rinsing washer to remove the oil, dust, and then pelletized! For post-consumer plastic bag scraps, after crushing, a friction washing machine is needed to remove oil and dust, and then pelletizing.

HDPE pipes recycling. HDPE pipes usually include drinking water delivery pipelines, agricultural irrigation pipelines, urban drainage pipelines and industrial wastewater pipelines.

Shuliy-80 Heavy-duty shredder Specially designed for shredding HDPE pipes, quickly shredding plastic pipes. After shredding and cleaning, the high temperature of 300 to 400 degrees Celsius melts and plasticizes the plastic, and finally extrudes it into HDPE recycled pellets, which are used to make new products, such as plastic bottles, building materials, garden supplies, etc.

HDPE crate bottle container regrind recycling. HDPE Regrind is a small pellet or fragment that is typically recycled from discarded HDPE products or waste materials from manufacturing processes and is cleaned, crushed and processed.HDPE Regrind materials are often used as a replacement for virgin plastic raw materials as a feedstock for the manufacture of new plastic products.

HDPE bottles recycling. HDPE bottles usually include mineral water bottles, chemical bottles, medicine bottles, shampoo bottles, shower gel bottles, food packaging bottles, industrial use bottles, lubricant bottles and so on.

HDPE bottles need to be thoroughly cleaned to remove residues, labels and adhesives from the inside and outside of the bottle. Label and cap removal: labels, caps and other appendages also need to be removed. The cleaned HDPE bottles are placed in a shredder machine that pulverizes them into smaller chips. These fragments are called HDPE flakes or regrind for further pelletizing.

Learn more about recycling machine:

HDPE Plastic Recycling Significance to Circular Economy

Reducing production costs. Purchasing new plastics requires a lot of energy and costs, which can be significantly reduced by factories recycling HDPE trimmings and remnants. In addition, recycled HDPE sheet manufacturers, for example, use recycled HDPE materials for production, which not only saves the cost of raw materials, but also reduces energy consumption.

For plastics producers, recycling HDPE can improve economic efficiency and support environmental protection at the same time.

Reducing waste and environmental pollution. Recycling of HDPE can effectively reduce the generation of plastic wastes and prevent these wastes from being sent to landfills or entering the natural environment, causing pollution problems.

By converting HDPE waste into valuable recycled materials, the negative impact of plastic waste on soil, water and marine ecosystems is reduced.

Promoting sustainable development. HDPE Recycling supports a circular economy development model for the plastics industry. Through a closed-loop recycling system, HDPE materials can be recycled multiple times, creating a sustainable production and consumption system.

This recycling not only helps reduce the environmental footprint but also promotes a green economy.

Stimulating innovation and employment opportunities. Recycling project of HDPE promotes technological innovation and industrial chain upgrading, giving rise to new markets and business models. Recycling enterprises and manufacturers of recycled plastics benefit as a result.

In addition, the prosperity of the recycling industry also brings a large number of employment opportunities, which promotes the diversification of the economy and the sustainable development of society.

Shuliy Helped Oman Client with HDPE Recycling

One of Oman’s leading plastics recycling plants installed a complete set of HDPE recycling machines in 2023 and they are very happy with the solution that Shuliy provided them to process the plastic scrap from their plastics.

Learn more about the case: Shuliy Recycling Machine installed in Oman

“With the help of Shuliy’s plastic recycling machine, we reuse the HDPE scrap and smoothly produce recycled pellets which will generate revenue for us.” said the head of the recycling plant in Oman.