Industrial Tire Shredder for High-Volume Tire Recycling | 2-20 Tons/hr Capacity

| Shredder model | 5 different models: SL-900-SL-1800 |

| Capacity | 2-20 tons/hr |

| Output size | 50-100mm |

| Warranty | 12 months |

You can now ask our project managers for technical details

Designed for scrap tire recycling centers, pyrolysis plants, and any business aiming to convert tire waste into a valuable commodity, our industrial-grade tire shredder is the powerful engine for your profitable operation. It efficiently processes mountains of end-of-life car, truck, and even heavy-duty OTR tires.

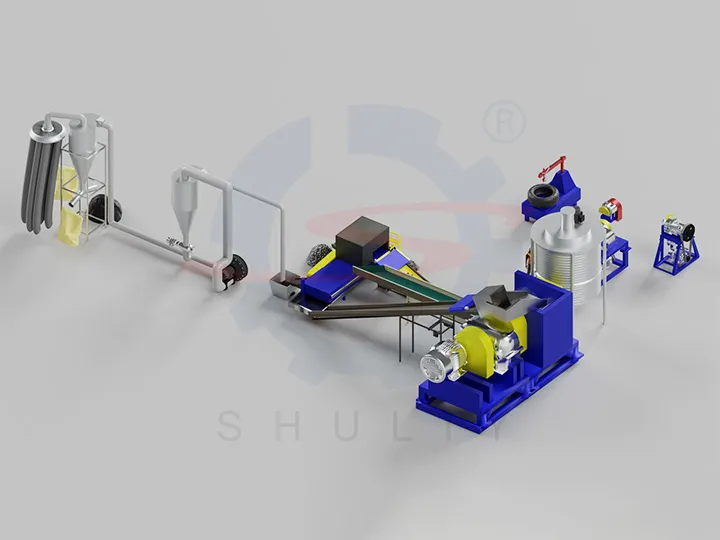

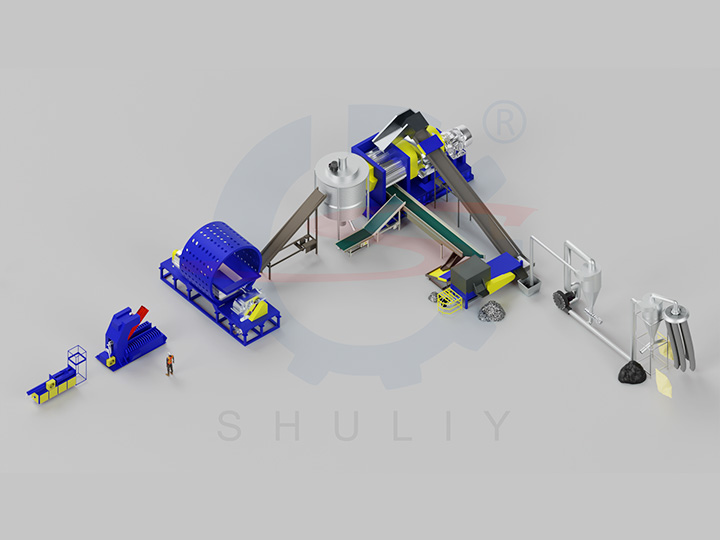

This machine is also called a rubber grinder machine, it is the critical first step in a complete rubber powder production line. Its core function is to shred whole tires into consistent, manageable 50-100mm blocks. This prepares the material perfectly for the downstream separation of high-value steel wire and the final grinding process into profitable rubber powder and granules. With a robust processing capacity of 2 to 20 tons per hour, it ensures your production line has a steady, reliable supply of feedstock.

Why Our Tire Shredder is a Smarter Investment for Your Business

Choosing the right equipment is the foundation of your success. Our tire shredder is more than just a machine; it’s an engineered profit center, designed to maximize your return on investment through superior performance and unmatched durability.

Unmatched Power & Throughput: Process More, Earn More

Equipped with a powerful drive system ranging from 64.5kW to 328.5kW, our shredder’s high-torque design tears through tough, steel-belted radial tires without hesitation, preventing jams and costly downtime. Whether you’re a startup processing 2 tons per day or a large-scale facility needing up to 20 tons per hour, we have a model scaled perfectly for your business, ensuring you can process more tires and generate more revenue.

Built for Durability: Lower Your Long-Term Operating Costs

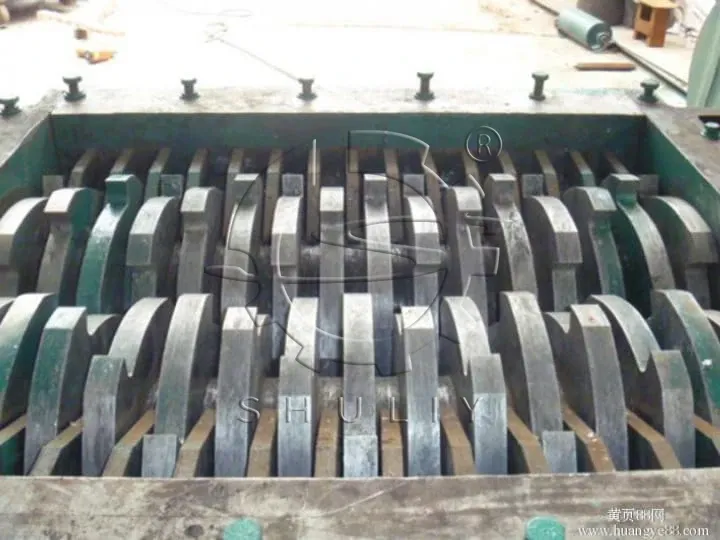

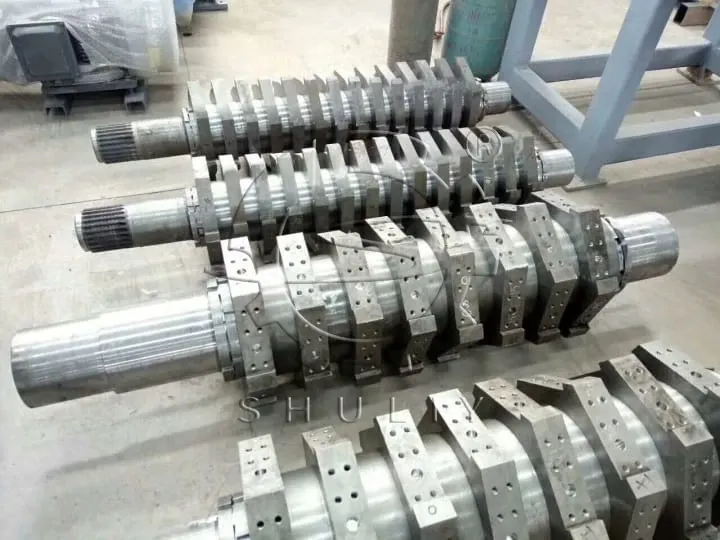

The substantial weight of our machines, from 10 to 26 tons, isn’t just a number; it’s your guarantee of rock-solid stability during operation. This heavy-duty steel construction absorbs vibration, reducing wear and tear for a longer service life. We use high-hardness, wear-resistant composite alloy blades, which means they last longer and need fewer replacements, directly cutting your long-term maintenance costs.

Consistent & Valuable Output: The Key to Higher Profits

Higher profit comes from high-quality output. Our tire shredder machine consistently produces uniform 50-100mm tire chunks. This material is ideal for producing high-quality Tire Derived Fuel (TDF) and is the perfect feedstock for our downstream rubber granulators. Crucially, the liberated steel wire can be sold directly as valuable scrap steel with a high market price, opening up a second, immediate revenue stream for your business.

The Heartbeat of Your Complete Tire Recycling Line

A single, efficient shredder is a great start, but the real profit potential is unlocked with a complete, seamlessly integrated rubber powder production line. Our tire shredder serves as the powerful heartbeat of the semi-automatic and fully automatic tire recycling machine systems we design for our clients.

We provide a complete, end-to-end solution, optimized for maximum efficiency:

Tire Pre-processing (e.g., debeading, cutting) → Primary Shredding (The Core Stage) → Steel Separation → Rubber Grinding/Granulating → Fine Screening → Nylon/Fiber Separation → High-Value End Products

Detailed Technical Specifications

We believe transparent, detailed data is the foundation for your best decision. The table below outlines the full specifications for our range of industrial tire shredder for sale.

| Model | Power | Output | Machine Size (LWH) | Weight | Footprint (LWH) | Feed Size | Output Size | Blade Dia. | Blade Thickness | Blade Qty |

|---|---|---|---|---|---|---|---|---|---|---|

| 900 | 64.5 kW | 2 tons/h | 4*2.2*2.8 m | 10 tons | 9*5*2.8 m | <900mm | 50mm | 360mm | 50mm | 16 |

| 1000 | 94.5 kW | 4 tons/h | 5*2.6*3.2 m | 13 tons | 10*6*3.2 m | <1000mm | 60mm | 440mm | 50mm | 16 |

| 1200 | 157 kW | 5-6 tons/h | 5*2.6*3.2 m | 15.8 tons | 10*6*3.2 m | <1200mm | 60mm | 510mm | 60mm | 18 |

| 1500 | 188.5 kW | 8-10 tons/h | 20*10*3.5 m | 18.6 tons | 20*10*3.5 m | <1200mm | 75mm | 580mm | 75mm | 20 |

| 1800 | 328.5 kW | 15-20 tons/h | 20*12*4 m | 26 tons | 20*12*4 m | <1400mm | 100mm | 650mm | 100mm | 18 |

Note: The configurations above are standard. We provide complete solutions from semi-automatic to fully automatic lines, which can be customized based on your specific feedstock and final product requirements. Please contact our engineers for a complimentary consultation and system design.

Frequently Asked Questions

Blades are the main wear part and a significant operating cost for a industrial shredder. What is the specific material of your blades, what is their realistic operational lifespan, and what are the costs and procedures for replacement or maintenance?

This is a core concern. Our industrial shredder blades are forged from a high-hardness, high-toughness composite alloy steel, which undergoes multiple heat treatment processes. Under standard operating conditions (processing passenger and truck tires without excessive contaminants), the blade edges can process several thousand tons of material before requiring maintenance. Critically, the blades feature a rebuildable design. When the edges wear down, you do not need to replace the entire set. Instead, your technicians can restore their performance through professional hard-face welding and grinding. This can reduce your long-term operating costs by over 70%. We provide a detailed maintenance guide for this procedure.

Q: Our feedstock includes a large volume of steel-belted radial truck tires and occasionally some smaller OTR tires. What is the risk of the shredding equipment jamming or overloading when processing these high-strength materials?

Our tire shredding equipment is specifically engineered for such demanding conditions. Firstly, the high-torque planetary or hypoid gear reducer provides immense shredding force. Secondly, all models come standard with a PLC-controlled intelligent overload protection system. If the system detects a sudden torque spike, the shafts automatically reverse to release the material, then rotate forward again to re-attempt shredding. This process repeats automatically, allowing the machine to work through the vast majority of tough materials, effectively preventing jams and protecting the motor and gearbox from damage.

You mention an output size of 50-100mm. How do you guarantee the consistency of this size? Our downstream rubber powder line has strict requirements for feedstock uniformity.

The uniformity of the output size is ensured by two key design factors: the thickness of the blades and the spacing of the blades on the shafts. These parameters are precisely calculated and fixed during the machine’s design and manufacturing, ensuring a consistent and stable output of properly sized tire chunks. For example, the Model 900 consistently produces an output of approximately 50mm. While the shredder’s primary role is coarse shredding, its stable output is fundamental to the efficiency of your subsequent fine grinding and screening processes.

Do we have to purchase your entire rubber powder production line? If we only want to buy a single rubber shredder to upgrade our existing line, what about compatibility?

You can absolutely purchase the rubber shredder as a standalone unit. We understand the need to upgrade existing facilities. Before your purchase, our engineers will communicate with you in detail, providing all necessary drawings for the in-feed and out-feed ports, height specifications, foundation bolt patterns, and electrical control interface requirements to ensure it integrates seamlessly with your existing conveyors and workflow.

You mentioned the tyre shredder for sale saves up to 1/3 of the energy compared to traditional machines. How is this achieved?

This energy-saving advantage of Shuliy tyre shredder for sale comes from our optimized transmission system. We utilize a design with up to eight double-row roller bearings. Compared to traditional sleeve bearings or standard bearings, their friction coefficient is extremely low, which significantly reduces energy waste and heat generation during operation. Paired with a high-efficiency reducer, this ensures more of the motor’s power is converted into effective shredding torque, resulting in substantial energy savings.