Stretch Film Recycling Machines and Solutions

Over the years, stretch film has gained popularity for its use in the packaging industry, and as demand and production have increased, so has its waste. Some plastics producers have begun recycling it to enhance the sustainability of their plants!

What Is Stretch Film?

Stretch Film, also known as wrap film, is typically made from Linear Low-Density Polyethylene (LLDPE), a material known for its strength and elasticity that provides excellent protection. The primary function of stretch film is to stabilize, bundle and protect goods, especially during transportation and storage.

Advantages of Stretch Film Recycling?

For plastic film producers: Recycling of stretch film is becoming a major trend in the plastics production industry, bringing significant sustainability, economic benefits and recycling advantages to the market. By recycling waste stretch film, stretch film manufacturers are not only able to significantly reduce their raw material costs, but they can also reintroduce the recycled material back into the production process, while ensuring that the quality of the finished product remains at a high standard.

For plastic recycling centers: In addition, stretch film recycling is a lucrative opportunity for recyclers. Many plastics recycling centers are actively seeking renewable recycled materials, and large quantities of stretch scrap allow them to capitalize on the business opportunity. Recyclers collect plastic waste from factories, process it into pellets, and sell these pellets to plastic manufacturers, creating a highly profitable business model.

Cost-Effective Solution for Stretch Film Recycling

Recycled stretch film can be processed through the following steps:

Collection & Sorting: Waste stretch film first needs to be collected and separated from other types of plastic waste.

Cleaning and Shredding: Stretch film usually needs to be cleaned in order to remove any dust, grease or other contaminants that may have adhered to the film. After washing, the stretch film is crushed into small pieces or pellets.

Melting and Recycling: The crushed pellets are reprocessed through a melting process into plastic pellets. These recycled pellets can be used to produce new plastic products such as garbage bags, agricultural film or construction materials.

How to Select the Right Machine for Stretch Film Recycling?

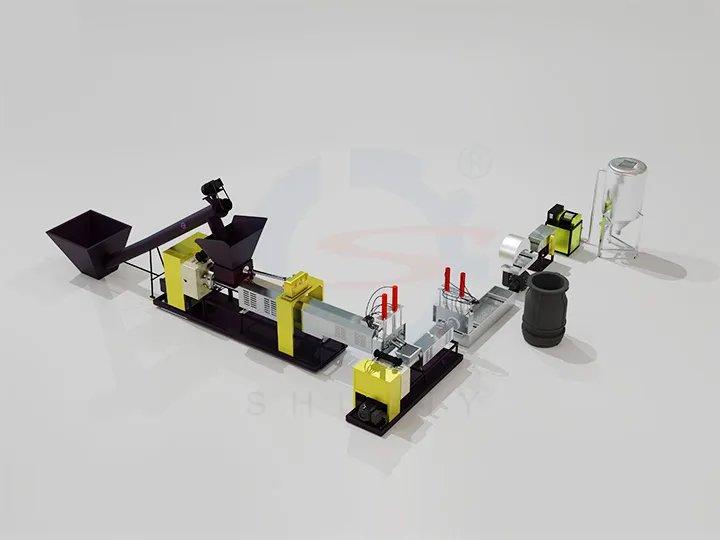

The innovative Shuliy shredder shreds plastic waste quickly. It selects a large-diameter screen to serve the shredded film material and improve its recycling efficiency. Stretch film producers can streamline the recycling process by removing the paper core and feeding the plastic waste directly to a belt conveyor.

If you are a recycling center or recycling plant, the odds are that your film material is dirty, and the Shuliy shredder is designed with the ability to connect a hose to fill it with water for a pre-wash effect.

The Shuliy granulator is a versatile recycler that can handle many types of plastic film such as garbage bags, shrink wrap, plastic bags, film scraps and bag cut-offs. The Shuliy pelletizer is therefore ideally suited to plastic film producers whose plastic waste can be diverse, both in shape and type.

In conclusion, recycling stretch film isn’t just about saving money or making a profit, it’s a meaningful move to protect the planet’s environment. Adopting a better solution than letting plastic go into landfills, reduces white pollution and creates a healthier environment for everyone.