How to Process Plastic Shrink Wrap Recycling?

What Is Shrink Film?

Plastic Shrink Film is a film material that shrinks when heated and wraps tightly around an item. This material is usually made of PVC and PE. They are widely used in the packaging field, especially in the packaging of food, beverages, electronic products, toys and books.

Plastic Shrink Wrap Recycling Solution & Machines

Plastic shrink film may be contaminated during use, so it is important to choose the right film washing equipment. Below are a few steps for plastic shrink-wrap recycling and recommended film recycling machines:

Shrink Film Washing Process

If the PE shrink film is dirty, the top of the plastic crusher can be installed according to the user’s needs of the water pipe, in the crushing of the film material for the injection of water. The above design realizes the film crushing and cleaning at the same time, which is the coarse washing of the plastic film.

The second washing step is friction washer equipment. The spindle inside the equipment generates strong centrifugal force and friction force through high-speed rotation and rinses through the water flow phase, which can effectively remove the stains and impurities on the surface of plastic film. The inner wall of the washing machine is equipped with specially designed baffles to enhance the cleaning effect and prevent the plastic film from being knotted or entangled during the cleaning process.

After the initial cleaning in the friction washer, the film material is transported to the rinsing tank for precision cleaning. In the rinsing tank, effluent and contaminants are separated and rinsed out to further remove stains from the shrink PE film surface.

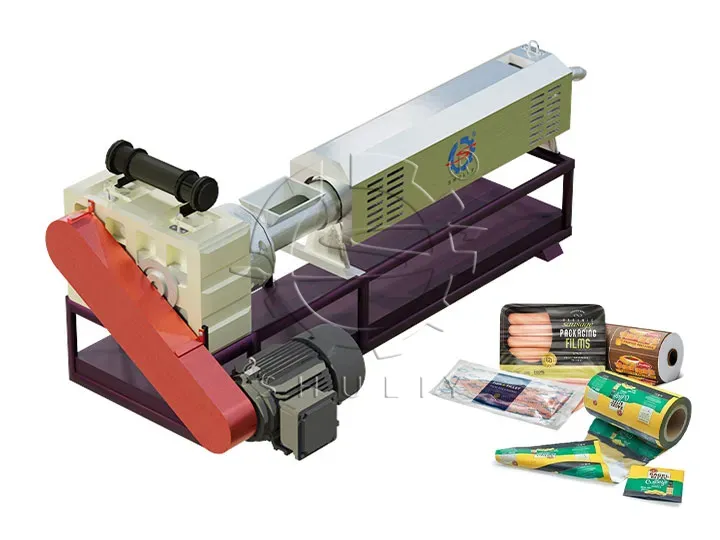

Plastic Shrink Wrap Film Pelletizing Process

Shuliy’s Plastic Pelletizer for shrink film recycling is an efficient and intelligent machine designed specifically to convert used plastic films into economically valuable plastic pellets. Waste PE films will be melted, plasticized, and extruded under 300-400 degrees Celsius. A cooling tank will reduce the temperature and make the plastic hard. Shuliy provides a strand pelletizing system and a water-ring pelletizing system, we will suggest the most fittable one according to your needs.

Plastic pellets produced through Shuliy’s plastic granulators have high market demand and economic value. These pellets can be widely used in the production of various plastic products, helping customers to turn waste plastic films into treasure and create a new source of profit.