What Machine Is Used for Plastic Regrind Recycling?

Plastic regrind recycling and reuse help to reduce dependence on virgin plastics and lower manufacturing costs. This type of recycling has significant environmental and economic benefits, so many plastics manufacturers and recyclers have started programs to recycle plastics for profit. Plastic regrind materials are also becoming more common in the plastics industry.

What Is Plastic Regrind Material?

“Plastic regrind” refers to the plastic granules or flakes obtained after the used plastic materials are mechanically processed by crushing and cutting.

It is usually derived from trimmings generated during the production process, used plastic products or plastic waste products after use by consumers.

The material covers various types of plastics, and common plastic regrind materials include the following:

- Polyethylene, PE

- Polypropylene, PP

- Polyethylene Terephthalate, PET

- Polyvinyl Chloride, PVC

- Polystyrene, PS

- Acrylonitrile Butadiene Styrene, ABS

- Polycarbonate, PC

- Polystyrene, PS

- Nylon

The most common of these regrind materials are various PP PE packaging materials, PP PE injection molded products, PP PC ABS automotive parts, PE bottles.

Plastic regrind material is an intermediate product in the recycling process, and after subsequent melting, plasticizing and granulating, it can be used as raw material to be put into the manufacturing process again and used to make new plastic products.

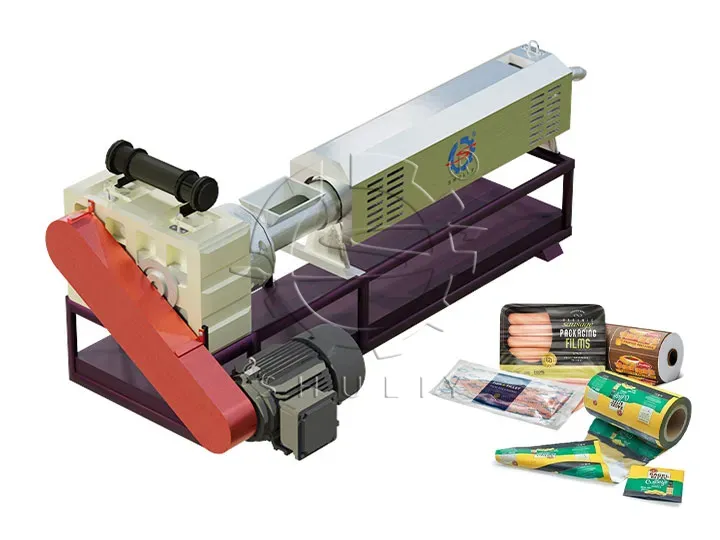

Shuliy Machines for Plastic Regrind Recycling

Every day there are many plastics from agricultural places, food or industrial packaging industry, injection molding, chemical industry, etc. These plastics need to be recycled and reused through plastic washing equipment. After the plastic washing step, the clean and dried plastic pieces are put into a plastic granulator to make pellets.

When you start a plastic recycling program, a professional cleaning step is one of the most important pieces of equipment to achieve your plastic recycling objects.

Plastic regrind can be easily processed using a pelletizer, helping businesses maximize resource efficiency, reduce waste, and contribute to a sustainable future. Shuliy pelletizers are designed to facilitate the recycling of all types of regrind materials, with outputs ranging from 100-500kg/h.

Whether you’re just starting in the plastics recycling business or are looking to expand your granule production capacity, we’ve got the right pelletizer for you!