Differences Between HDPE and LDPE & Recycling Guide

In the plastics recycling industry, HDPE (High-Density Polyethylene) and LDPE (Low-Density Polyethylene) are the two most common polyethylene materials. Although they are both made from the polymerization of ethylene monomers, HDPE and LDPE have significant differences in appearance, properties and applications due to differences in molecular structure. This article will detail the differences between HDPE and LDPE to help you better understand and how they can be recycled.

Appearance difference between HDPE and LDPE

HDPE Plastic Appearance

- HDPE products are usually white or opaque material, the texture is more hard, give a person a thicker feeling.HDPE is usually opaque, but after film processing can have a certain translucent.

- Due to its high density and rigidity, it is relatively hard to the touch, with better tear resistance and a harder product surface.

LDPE Plastic Appearance

- In contrast, LDPE has a more transparent, softer appearance, often with a glossy finish. In film applications, LDPE can achieve very good transparency and give the impression of lightness.

- LDPE products’ flexibility is better than HDPE, the surface is soft to the touch, and easier to bend and fold. lDPE is suitable for the production of such as plastic bags, food packaging and other products that require flexibility.

HDPE and LDPE performance difference

HDPE

The high-density structure gives HDPE high tensile strength and rigidity, allowing it to withstand greater pressure and weight, with excellent impact resistance. At the same time, HDPE is also more resistant to abrasion and is less likely to be deformed or damaged.

HDPE has better heat resistance, it can withstand higher temperatures, and will not easily soften or deform at high temperatures.HDPE has very good chemical resistance and is widely used in chemical tanks and pipelines.

Due to its superior strength and durability, HDPE is widely used in rigid plastic products such as plastic drums, pipes, bottles, toys, and plates. It is also used in construction materials, the automotive industry, and water pipes that can provide long-lasting performance.

LDPE

LDPE has softer mechanical properties, and lower tensile strength and is suitable for packaging of lightweight items. However, the heat resistance of LDPE is poor, easy to soften at lower temperatures.

Therefore, LDPE is not suitable for high-temperature environments, but it still has superior chemical resistance and is suitable for some lightweight packaging.

LDPE is commonly used as soft flexible packaging materials, such as food packaging bags, garbage bags, agricultural films, wire and cable insulation, heat sealing layers.

Recycling guide for HDPE LDPE scrap

Although HDPE and LDPE are different plastic materials, their recycling processes are generally the same and follow the following steps: sorting, cleaning, shredding, melting and pelletizing.

Read more:

The recycling process for both HDPE and LDPE begins with collection. HDPE is usually sourced from HDPE bottles, containers, rigid packaging, etc., whereas LDPE is mainly sourced from LDPE films, bags, food packaging, etc. The recycling process for both HDPE and LDPE starts with collection.

Sorting: Collected plastic waste needs to be sorted to ensure that HDPE and LDPE can be processed separately. Sorting is usually done manually or by automated sorting machines. The purpose of sorting is to ensure that different types of plastics are not mixed to avoid compromising the quality of subsequent recycling.

Removing impurity. During the recycling process, HDPE and LDPE plastic scraps are often covered with contaminants such as grease, food residue, dust, and other contaminants. Contaminants can affect the purity of the recycled material, thus reducing the quality of the recycled material. To solve this problem, modern plastics recycling plants often use highly efficient rinsing tanks and friction washers to remove these contaminants.

Melting: The crushed HDPE and LDPE plastic materials are fed into the plastic pelletizer to be heated and melted. (Note: The two materials cannot be mixed and pelletized at the same time.) the melting point of HDPE is high, generally between 130-145°C, while the melting point of LDPE is relatively low, about 105-115°C. The melting temperature needs to be regulated according to the characteristics of the materials when melting.

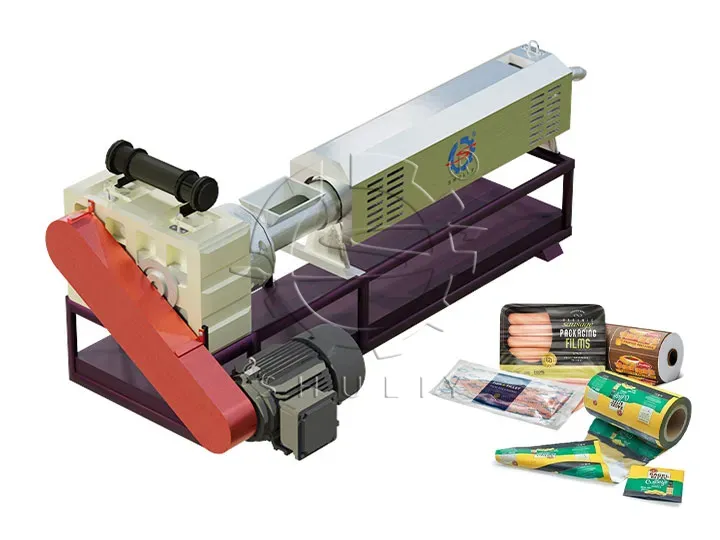

Pelletizing: During the melting process, the plastic material is extruded into uniform plastic filaments through a screw extruder, which is subsequently cooled and cut to form recycled HDPE/LDPE pellets. These recycled pellets are an important product of plastic recycling and can be used to replace virgin plastic in the manufacture of new products. They are much more cost-effective.

Reuse of HDPE and LDPE pellets

Recycled HDPE pellets and LDPE pellets can be used in the production of a wide range of products. For example, HDPE pellets can be used in the production of garbage cans, plastic containers, pipes, plastic trays, etc., while LDPE pellets can be used in the production of plastic films, shopping bags, garbage bags, agricultural mulch, etc.

Although recycled plastics may not be as strong and durable as virgin plastics, they still offer high economic value and practicality in many low-tech demanding applications.

Cost-effective LDPE HDPE recycling machine for you

HDPE and LDPE, as widely used polyethylene plastics, both have good recyclability and recycling value. Through systematic recycling and reuse, these two plastic materials can be recycled, reducing the impact on the environment while creating economic value for businesses.

However, for recycling plants, recycling cost is an important factor to consider in the recycling process. How to reduce recycling costs is one of the challenges for plastics recycling plants.

Shuliy Machinery uses highly efficient equipment, optimized energy use and innovative processes to design 3D drawings based on raw materials, site, budget and other factors before the customer purchases the machine, and design a variety of recycling solutions free of charge to the customer, Shuliy provides spare parts for the machine at cost for the lifetime of our customers, to help plastics recycling companies to reduce operating costs, thereby improving economic efficiency. Shuliy’s machines are designed to help recyclers reduce their operating costs and thus improve their economic efficiency.

While HDPE and LDPE each face certain challenges in the recycling process, the plastics recycling industry is moving toward a more efficient and environmentally friendly direction as recycling technologies continue to advance and innovate. If you have more needs or questions about recycling equipment or recycling processes for HDPE or LDPE, please feel free to contact us to learn more.