Plastic Shredder Machine for Scrap Cutting Grinding

| Shredder Model | SL-600, SL-800, SL-1000 |

| Cutting Matertial | Pipes, milk bottles, auto waste, electric waste, film, bags, ropes, tubs, bubble wrap, containers, chemical drum, etc. |

| Grinding Capacity | 600-1000kg/hour |

| Material Type | PVC, HDPE, LDPE, LLDPE, ABS, PP |

| Number of Knives | 10pcs |

| Material of Knives | 60Si2Mn |

You can now ask our project managers for technical details

The plastic shredder machine is manufactured by Shuliy Machinery combined with many years of research experience, which is also called a plastic scrap cutting machine and plastic grinder. The shredder is used to grind barrels, baskets, milk bottles, toys. Plastic crushers have the characteristics of large crushing force, high output, and long service life. Shuliy plastic shredders have been exported to Germany, Ghana, Saudi Arabia and other countries, and have been well received by customers.

Plastic shredder recycling machine working video

Raw materials of plastic scrap cutting machine

The plastic cutting machine can crush all kinds of plastic scrap such as PVC pipes, HDPE oil drums, paint buckets, plastic household waste, injection molded items, electric waste, PP car bumpers, PP/PE shopping bags, HDPE agricultural films, used woven bags, cement bags, T-shirt bag cutoffs, jerry cans, etc. The cutting machine can also grind defective products and production waste for plastic manufacturers.

Working principle of plastic shredder

When the shredding machine is working, the motor drives the internal blades to rotate at high speed. The rotating blades will produce an angle with the fixed blades when they rotate, and the blades forming the angle will cut the materials, thus crushing large pieces. The crushed plastic pieces will fall to the discharge port through the screen filter. Plastic pieces that do not meet the size will continue to be crushed until the size meets.

Crusher machine advantages

- The crusher knife type is reasonably designed, which is conducive to the material being crushed evenly.

- The rotating knife frame and bearings of the crusher are made of high-quality steel, which is not easy to wear or break.

- The plastic crusher feed hopper is enlarged to effectively avoid material leakage during the crushing process.

- It should be noted that when dealing with soft materials, a fan should be added to the grinder machine. Shuliy provides an extra fan for the film grinder.

Parameters of plastic shredder machine

Understanding the core data is the first step in selecting the right equipment. The SLSP series is designed with a clear correlation between power, throughput, and processing capability.

The following table shows the hot-sell models of the Shuliy plastic shredder machine.

| Shredder Model | SL-600 | SL-800 | SL-1000 |

| Motor power | 30 kw | 45 kw | 55 kw |

| Grinding capacity | 600-800kg/hour | 800-1000kg/h | 1000-1200kg/h |

| Material of shredding knives | 60Si2Mn | 60Si2Mn | 60Si2Mn |

| Number of shredding knives | 10pcs | 10pcs | 10pcs |

| Box width | 600cm | 800cm | 1000cm |

Precision Engineering for Measurable Efficiency

The performance of a industrial plastic crusher is defined by its engineering details. The SLSP series integrates several features that translate directly into lower operational costs and higher quality output.

1.The Adjustable Cutting System: A 0.5mm Difference

The gap between the 10 rotating knives and the stationary knives is critical. Our system allows for precise adjustment, enabling you to optimize the cutting process based on material type:

- Soft Films (LDPE, PP): A smaller gap (as low as 0.5mm) ensures a clean, scissor-like cut, preventing material wrapping and reducing fines.

- Hard Plastics (PET, HDPE): A larger gap (1mm+) provides aggressive crushing power and protects the blades from excessive shock loads. This adjustability, combined with a bottom blade that compensates for wear, can extend blade service life by up to 30% before resharpening is required.

Modular Screens: Controlling Output Size from 26mm to 50mm

The screen determines the final particle size of the crushed material. The SLSP series features a quick-change screen system for maximum versatility. Based on extensive testing:

- For Film Materials: A screen with a ø26mm aperture provides the ideal balance, producing flakes large enough for efficient washing without passing excessive fines.

- For Hard Materials: A ø50mm screen is recommended to maximize throughput while producing a uniform regrind suitable for pelletizing.

Wet & Dry Crushing Capability: Leveraging Water for Performance

For processing soft films, the SLSP series supports wet crushing. When processing 1000 kg/h of film, an injection of 1-2 tons of water per hour achieves three key objectives:

- Friction Reduction: It lubricates and cools the blades, preventing heat buildup that can cause soft plastics to melt and adhere to the rotor.

- Preliminary Cleaning: It performs a coarse wash, removing surface dirt and contaminants early in the process.

- Improved Feeding: It increases the density of light films, preventing them from floating above the rotor and ensuring consistent engagement with the knives.

Using precautions of plastic scrap cutting machine

- Install the plastic scrap cutting machine in a ventilated position, so that the motor can fully dissipate heat and prolong its service life;

- After the scrap cutting machine has been used for some time, it is necessary to add lubricant to the bearing to ensure the normal operation of the machine.

- Regularly check the knives and screws inside the shredder, and check whether there is looseness between the blade and the knife holder to ensure the safety of the machine.

Welcome to field research our plastic scrap grinder

Shuliy welcomes our customers to visit our factory, showing them our real production and processing capabilities. We always believe that a site visit is important when buying a plastic grinder machine. Because some manufacturers will boast and exaggerate their company’s capabilities in all aspects, if the customer does not seriously go to the site visit to see the plant environment, the quality of the equipment, the grinder test run, they will not know whether the truth is the same as the plastic scrap grinder machine manufacturer promised or not.

Plastic recycling shredder machine successful projects

Shuliy Machinery sent plastic recycling shredder and other recycling equipment to Oman, if interested, you can read more info on this page: PET recycle machines shipped to Oman

Feel free to contact us to learn more about plastic scrap machine price.

Plastic shredder machine for recycling HDPE baskets shipped to Oman

The video shows our HDPE scrap grinder in Oman, our clients purchased our plastic pelletizing line, including a shredder for grinding HDPE scrap, a pelletizer, a washing tank, and a dryer. More details and videos you can get by reading the case: HDPE plastic recycling line in Oman

Two PVC scrap grinders exported to Ghana

Our plastic crushers have been exported to Ghana. The Ghanaian customer has his own manufacturing company and now he wants to get into the plastic recycling business. He wanted to buy a few recycling machines to try out first. Therefore he found our sales manager Sunny on our website. After talking with the customer, he bought two PVC scrap grinders, model SL-600, with 22KW power and 600-800kg/h. If everything goes well with those grinders, he will buy the whole pelletizing line later.

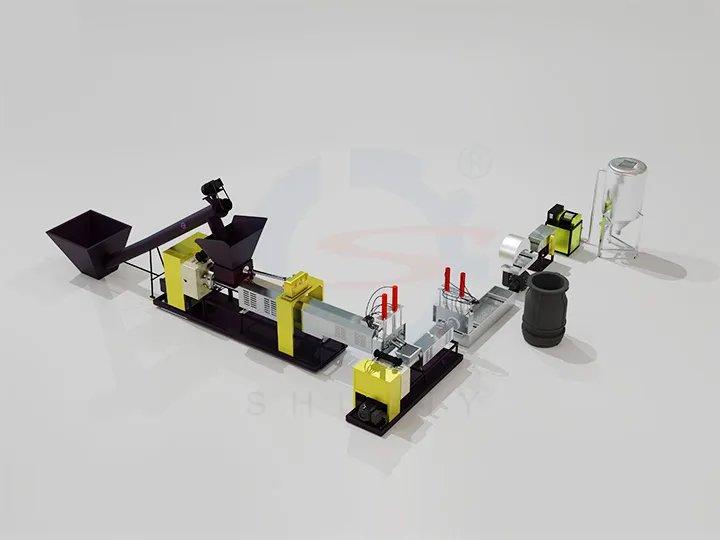

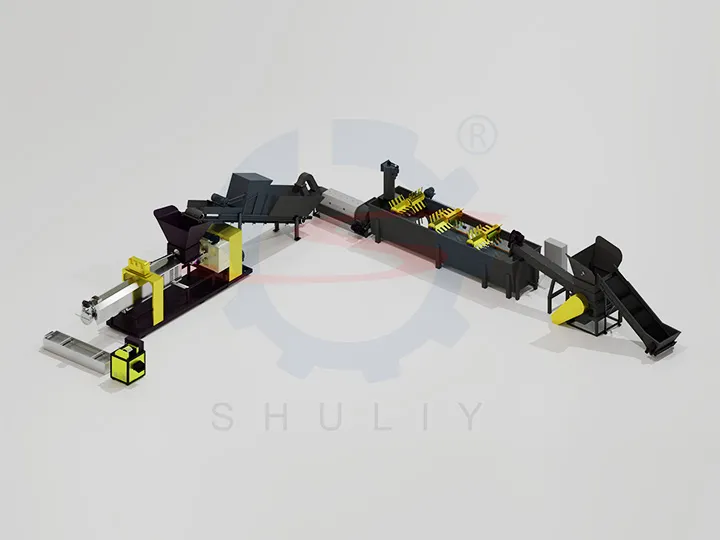

A Core Component in Your Complete Plastic Recycling Line

A crusher does not operate in isolation. It is the heart of a larger system. We design and supply complete solutions where the SLSP series integrates seamlessly with downstream equipment. For example, the output of our Industrial Plastic Crusher Machine is perfectly matched to our friction washers, which utilize specialized U-shaped augers for film processing to prevent clogging and simplify maintenance. This system-level approach ensures there are no bottlenecks in your production.

Plastic scrap cutting machines are usually used in plastic recycling plants, often paired with plastic pellet machines to form a complete plastic pelletizing line. Plastic pellets can be sold directly into recycled plastic products with high economic benefits.

If you are interested in the plastic recycling business, welcome to consult Shuliy Group or leave messages on our website. We will recommend the most fittable machines for you.

SLSP Series Industrial Plastic Crusher – Key Questions & Answers

Q: When processing different materials, for example, switching from rigid PET bottles to soft LDPE film, how long does the entire changeover process take? What specific adjustments are involved?

A: A skilled operator can complete the entire changeover process in approximately 30-45 minutes. It primarily involves two core steps:

- Blade Gap Adjustment: Using adjustment bolts to change the clearance between the rotating and stationary knives from ~1mm (required for hard plastics) to ~0.5mm (optimal for films).

- Screen Replacement: Removing the retaining bolts, sliding out the screen for hard plastics (e.g., ø50mm), and inserting the screen for films (e.g., ø26mm). Our design simplifies these procedures to maximize your production uptime.

Q: Knives are the primary wear part. What is the expected service life in hours for the standard 60Si2Mn blades when processing moderately contaminated post-consumer plastics? How does their performance compare to the upgraded D2 (SKD-11) steel?

A: The standard 60Si2Mn blades are known for their high toughness and impact resistance. Under standard operating conditions, the effective life of a single cutting edge is typically between 500-800 working hours before resharpening is needed. A set of knives can be resharpened 2-3 times.

Upgrading to D2 (SKD-11) tool steel significantly increases hardness and wear resistance, especially for abrasive materials like glass-filled plastics, extending the service life by 50%-70%. However, it has slightly lower toughness, making it more sensitive to metal contaminants.

Q: Under what ideal conditions is the “Capacity” listed in the technical specifications (e.g., 1000-1200 kg/h for the SLSP-1000) measured? In actual production, what are the key variables that affect throughput?

A: The listed capacity is benchmarked under ideal conditions: continuous and uniform feeding of clean, high-density hard plastics (like PET bottle flakes) using a large-aperture screen (≥50mm).

In practice, the four most critical variables affecting throughput are:

Q: What are the specific safety mechanisms of your Industrial Plastic Crusher Machine? How does it respond to an accidental intake of an uncrushable object like a metal fragment?

A: Safety is paramount in our design. The crusher is equipped with:

- Overload Protection: An amperemeter in the control cabinet monitors the motor load and triggers an automatic shutdown to prevent damage.

- Safety Limit Switches: The machine will not operate if the hopper or chamber door is open.

- Emergency Stop Buttons: Located for immediate access. These features work together to protect both the operator and the investment in your equipment.

Q: Regarding the Wet Plastic Crusher for Film capability, does long-term water injection cause corrosion in the bearing housings or machine body? What specific anti-corrosion measures are in place?

This is a key design consideration we have fully addressed. Our wet plastic crusher features:

- Enhanced Sealing: A multi-layer seal structure protects the main shaft bearings from water and dust ingress.

- Anti-Corrosion Coating: The crushing chamber interior is coated with high-quality, durable paint.

- Efficient Drainage: The machine base is designed for rapid water evacuation to ensure longevity even in continuous wet granulation operations.

Q: The V-type cutting geometry of your Adjustable Blade Plastic Crusher is interesting. How does it directly impact energy consumption compared to other designs?

A: You are correct, the “V-type” cutting action is a key energy-saving feature. Unlike a flat-blade design that creates a single high-impact chop, the V-shape creates a progressive, scissor-like cut. This significantly reduces the peak motor load and overall power consumption of the plastic grinder, resulting in documented energy savings of 15%-20% for the same output.

Q: What is the operational noise level of the shredder, and do you offer soundproofing solutions?

A: As a powerful heavy-duty plastic crusher, the operational noise level is approximately 90-95 dB at no-load and can reach 105 dB when processing hard plastics. For facilities with strict noise regulations, we offer an optional full soundproof enclosure, which effectively reduces the noise level by 15-20 dB.

Q: When we receive a quote for your Plastic Crusher Machine, what is included in the standard price, and what are the main optional accessories?

A: The standard quotation includes the main crusher unit (with one set of knives and one screen installed) and the electrical control cabinet. Key optional accessories include spare knives and screens, feeding conveyors, material discharge systems, and the soundproof enclosure. We provide a fully transparent quote.

Q: As a Plastic Crusher Supplier in China, what is your after-sales service policy for international clients, especially concerning spare parts availability?

A: We provide a comprehensive 12-month warranty and lifetime technical support. We maintain a ready stock of critical wearing parts like knives and screens. For international clients, we can typically dispatch standard spare parts by air freight within 48 hours of order confirmation to minimize your downtime.

Q: What is the standard production lead time and can you assist with international shipping?

A: The standard production lead time for our Industrial Plastic Crusher Machine models is 30-45 working days. Our experienced logistics team can manage the entire shipping process for you, from booking freight to handling customs documentation, ensuring a smooth delivery to your designated port.