Plastic Film Washing Machine for LDPE PP recycling plant

| Length | 15-20m |

| Qty of rotating wheel | 10 |

| Distance between every two wheels | 1.5-2m |

| Appication materials | PP PE PVC PS plastic waste |

You can now ask our project managers for technical details

A plastic film washing machine is one of the common plastic cleaning equipment used in plastic film recycling lines for rinsing plastic shreds and removing sticker residue from plastic. The plastic washing tank is made of stainless steel, which is not easy to rust and has a long service life.

Application of plastic film washing machine

The PE film washing machine mainly cleans plastic film pieces. After the plastic film shredder crushes the waste plastic bags, the plastic waste is still dirty. Since there are many oil stains, dust, paint and other stains on the plastic bag, it needs to be cleaned before granulation. Therefore, it is very necessary to send it to the plastic cleaning tank so as to improve the quality of the recycled pellets and increase economic efficiency.

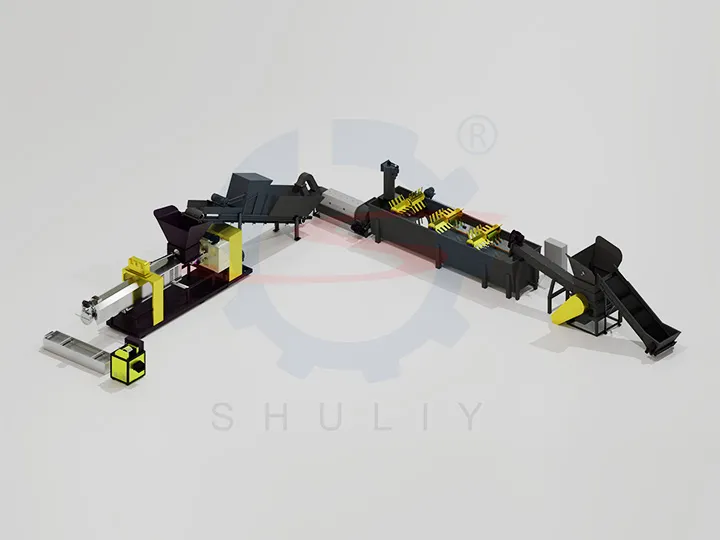

Working principle of plastic washing machine

The plastic recycling washing machine is mainly composed of the water tank, rotating gear, drainage port and other structures. When the plastic piece enters the water tank, the rotating gears will drive a large amount of plastic to tumble and clean during the rotation, and convey it to the next gear. A total of ten gears are installed on the water tank, and the circular tumbling will make the plastic clean.

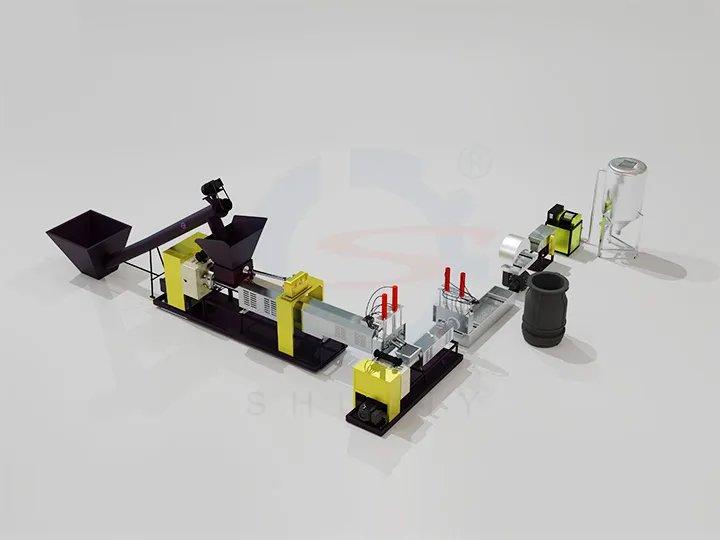

Plastic washing tank factory display

A total of 10 rotating gears are needed, the distance between every two mixing wheels is 1.5-2 meters, and the length of the whole machine is about 15-20 meters. The color of the rising machine can be customized by our customer’s demands.

In the complete plastic recycling line, the rinsing tank is always connected with a dewatering machine, which used to lift the materials in the tank and remove their extra water.