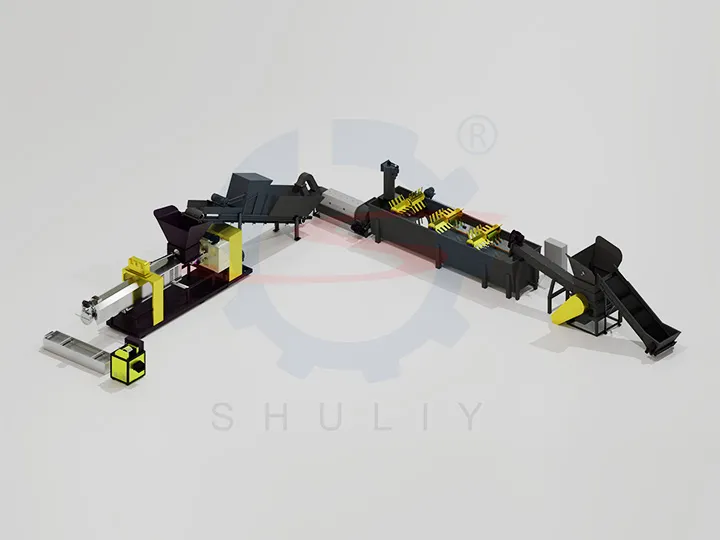

Pelletization Machine for Rigid Plastic Recycling

| Recycle Material | Pipe, Automotive waste, Chemical drum, Food container, Electronic waste, Pallets, Injection molded products, oil cans, Cosmetic tube |

| Material Type | HDPE, PP. ABS, PA, PC, PVC |

| Output Range | 100-500 kg/h |

| Final Product | High-quality plastic pellets/granules |

| Cutting Type | Strand pelletizing system, Water-ring pelletizing system |

| Cooling Type | Water cooling |

You can now ask our project managers for technical details

Shuliy pelletization machine for rigid plastic recycling offers an easy and quick solution for recycling plants and plastic producers. The dirty rigid plastic like HDPE milk bottles, shampoo bottles, pipes, barrels, drums, toys, defective production cut-offs, waste residential electric meters, etc., they will be processed to small and round plastic granules by some plastic recycling machinery. The end products are fully clean granules that can be reused for manufacturing. Our rigid plastic recycling machinery has capacities from 100kg/h to 500kg/h.

Rigid plastic recycling principle

A plastic pelletizing machine for plastic recycling is suitable for producing PP, PE, PS, ABS, PA, PVC, PC, POM, and other kinds of plastic recycling. After the plastic enters the screw from the hopper, the plastic is transported forward under the action of the rotating screw, and the loose solid plastic begins to be compacted.

At the same time, under the action of the heating ring outside the barrel and the constant friction between the screw and the material inside the barrel, the temperature of the plastic rises continuously, and finally, when the temperature of the plastic reaches the melting point, it begins to melt.

At the end of the compression section, all the materials are transformed into a viscous flow state, but at this time the temperature of each point is not yet uniform, after the homogenization section of the homogenization of the role of a more uniform, and then the screw will be the molten material quantitatively, fixed-pressure, fixed-temperature extrusion into the head.

The head of the die mold is a molding part, the material is through it and gets a fixed size of the plastic strip, and then after the cooling and cutting process, you can get the molded plastic recycled particles.

Features of rigid plastic extruder pelletizing machine

- Our rigid plastic extruder pelletizing machine is reasonably designed, with a high degree of automation, good product quality, uniform particle size and pure color, meeting the requirements of the international market.

- The plastic pelletization machine exterior adopts a fully enclosed safety shield, one is to avoid the operator due to high temperature and scalding, in addition to avoiding the problem of electrical leakage, but also play a role in heat preservation.

- The pelletization machine uses the best quality motor, with the pelletization machine high-speed operation of the motor is the most prone to problems, we use China’s best quality motors, to ensure that the granulator can be a long and smooth operation.

- As the founder of the recycled plastic pelletization plant risk is small, the size of the investment can be, the entrance door is also low. Investors can start from a plastic pelletizing recycling line, but also at the same time to start a number of sets of recycling machinery.

Warranty and services of rigids pelletization machine

Each recycling machinery comes with a limited warranty. Shuliy Group provides 12 months for our plastic pelletizing machine for plastic recycling. We also provide site installation, our project manager will go to your country and help you with machine installation.

Pelletizer additional images

Inquiries for rigid plastic pelletizer machine

To get limited pelletizer machine prices and lead times, send us a message using the form in the lower right corner.

Our professional sales manager will be happy to send you the recycling machinery details soon.