What are the differences between plastic soft film material and hard material granulation?

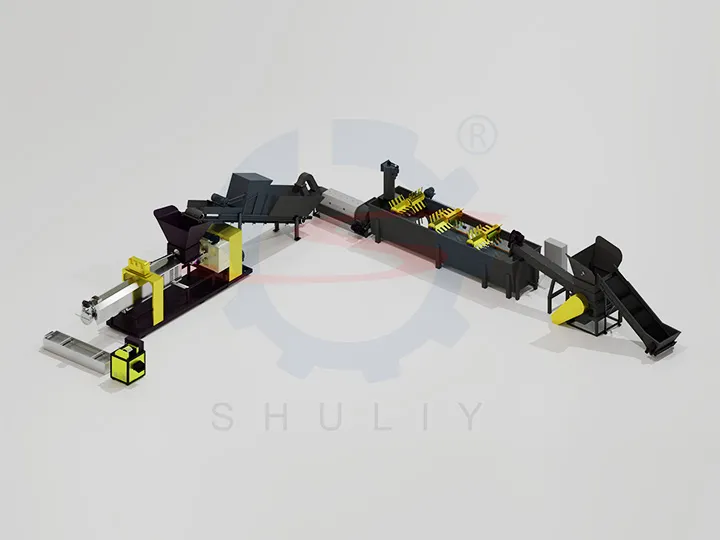

Plastic recycling extruder machines are essential in the granulation process of plastic materials. When it comes to plastic granulation, there are two types of materials to consider: soft film and hard material. In this article, we will discuss the characteristics and differences between these two types of materials in the plastic granulation process.

Soft film material plastic granulation process

Soft film materials are thin and flexible, such as plastic bags and wrapping films. To granulate soft film materials, a plastic recycling extruder machine with a high-speed rotating cutter is used. The material is first fed into the extruder, where it is melted and compressed. Then it is sent through the cutter, which cuts the melted material into small pellets.

When granulating soft film materials, it is important to control the temperature and speed of the plastic recycling extruder machine. This is because if the temperature is too high, the material may burn, while if the speed is too high, the material may not melt evenly.

Hard material plastic granulation process

Hard materials are rigid and tough, such as plastic bottles and containers. To granulate hard materials, a plastic recycling extruder machine with a single or twin screw is used. The material is fed into the extruder, where it is melted and compressed by the screw. The melted material is then pushed through a die, which shapes it into small pellets.

When granulating hard materials, it is important to consider the size of the die, the speed of the screw, and the temperature of the extruder. If the die is too small, the material may not be properly shaped, while if the screw speed is too high, the material may not be evenly melted.

Differences between soft film and hard material granulation

The main difference between granulating soft film materials and hard materials is the type of plastic extruder used. Soft film materials require high-speed rotating cutters, while hard materials require single or twin screw extruders. Additionally, the temperature and speed of the extruder must be carefully controlled for both types of materials to ensure high-quality pellets.

Conclusion

In conclusion, plastic extruder machines are essential in the granulation process of plastic materials. The selection of raw materials and the quality requirements vary depending on the type of material being granulated. Soft film materials require a different approach than hard materials due to their unique characteristics. With the right equipment and processes in place, plastic pelletizing can be an efficient and sustainable process.