EPS Foam Melting Machine for Plastic Foam Recyclings

| Machine Brand | Shuliy Machinery |

| Model | SL220, SL880, SL1000 |

| Inlet Power | 3 kw |

| Capacity(kg/h) | 100-250 |

| Warranty | 12 months |

| Raw material | Plastic foam |

You can now ask our project managers for technical details

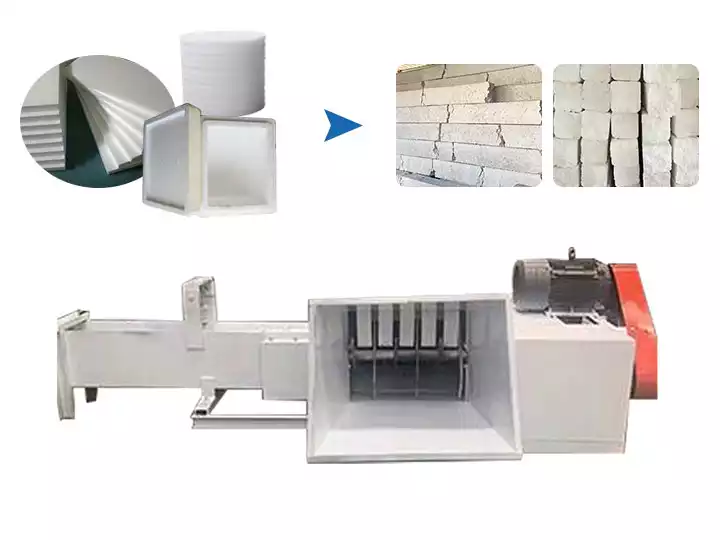

Shuliy EPS foam melting machine is also called a styrofoam densifier. It is used to crush and melt plastic foam at high temperatures. After crushing and heating, the EPS foam becomes the densified EPS ingots, and volume reduction ratio up to 90:1. The foam densifier machine not only can reduce the problem of white pollution, but also can bring great economic benefits after recycling foam into granules. Therefore it is a necessary equipment for plastic recycling manufacturers. If you are interested, please contact us.

Introduction of polystyrene densifier for sale

Polystyrene densifiers for sale can recycle Styrofoam(Polystyrene/EPS/Foam 6), which is widely used for insulation and product protection material during transportation. After the crushing is finished, they will be pushed by the screw to the heating area, after heating and plasticizing, the plastic raw material will melt into a heap, which is easy to transport and sell.

The materials that the machine can handle include foam fast food boxes, foam packing boxes, cake boxes, insulation materials, outer packaging foam of electrical appliances, and other white foam waste.

Working principle of EPS hot melting recycling machine

The EPS foam melting machine adopts double shaft crushing blades, which are two parallel blade shafts, and they rotate in different directions. Each blade shaft has 18 blades and is driven by a gearbox to crush the material, which is conveyed to the barrel through a screen. The foam is conveyed to the heated barrel by a high-speed rotating screw. The plastic foam will then be melted at high temperatures and extruded into a heap to flow out.

Advantages of styrofoam densifier

- This styrofoam densifier adopts manual loading, the material is quickly crushed by the double shaft blades and then conveyed to the host barrel through the screen, the machine is highly efficient.

- The host screw conveys and heats the material to the melting state, then extrudes it and the hydraulic blade cuts it into pieces for easy storage and transportation.

- The molten material coming out from the styrofoam densifier can be collected by steel trough to get the blocks, or cut by a cutting machine to get small blocks, which is convenient for the transportation of plastic foam.

- The EPS densifier’s appearance can be designed according to customer requirements.

EPS densifier hot melting machine parameters

| Model | Machine Size (mm) | Inlet Size (mm) | Configuration Power (kw) | Inlet Power (kw) | Capacity(kg/h) |

| SL220 | 1500*800*1450 | 450*600 | 15 | 3 | 100-150 |

| SL880 | 1580*1300*850 | 800*600 | 18.5 | 3 | 150-200 |

| SL1000 | 1900*1580*900 | 1000*700 | 22 | 3 | 200-250 |