What Are Your Plastic Scrap Recycling Solutions for Your Factory?

How do you recycle production waste and trimmings in your factory? Manufacturers increasingly recognize the importance of recycling the plastic scrap generated in their factories. Smart plastics producers do plastic scrap recycling, including defective products and plastic trimmings to reduce production costs. This can be accomplished by providing each plant with the right recycling solution and a reliable plastics recycling machine.

Benefit of in-house recycling

Recycling factory waste, such as polyethylene and polypropylene, not only helps to save money but also increases resource efficiency. These materials are produced and reproduced in the plastics industry, and by implementing an effective recycling strategy, manufacturers can ensure that these materials are continually recycled back into the production process.

Implementing the right recycling program

To achieve successful recycling results, manufacturers must invest in recycling programs tailored to their specific needs. This includes deploying high-quality plastic recycling machines capable of handling all types of plastic waste, including factory film waste, raffia waste, and injection molded items. In this way, factories can efficiently process waste into reusable plastic pellets that can be used directly in factory production.

As a manufacturer of recycling machines, not only do we provide our customers with smooth-running plastic recyclers that produce high-quality products, but Shuliy also provides operational advice and solutions that are tailored to your recyclables. Producers can choose from a variety of recycling options offered by Shuliy.

Shuliy solutions for different plastic scrap recycling

For factory film waste

Recycling industrial waste film materials can help you save on production costs. Industrial waste film materials include laminate film/multi-layered film, stretch film, bubble wrap, shrink film, fully printed film, metalized film etc. If your material is 100% from your production, then your material is It is very clean and does not need to be washed and can be recycled directly into shredders and pelletizers. The reusability of the granules is 100% and you can reuse them directly in the factory line.

- Machines for factory film waste

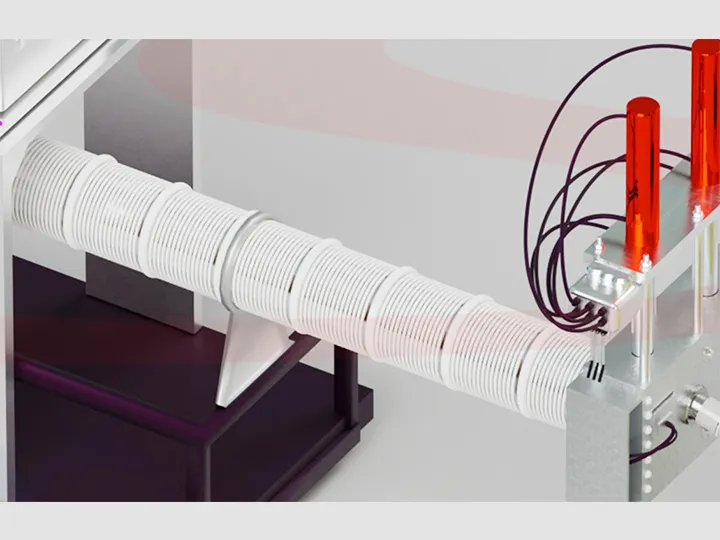

The Shuliy film recycling line is designed to recycle PE (HDPE, LDPE, LLDPE) and PP flexible packaging scrap.

The recycling solution is equipped with a film shredder, which eliminates the need to wash the material and crushes it directly into 3-5 cm film flakes, which are fed directly into the granulator using a conveyor to ensure optimal granulation.

- For more information about this product: Product Information: Shredder Machine – Film Pelletizer

For factory injection molded item

Recycling injection molding defective products can help plastic factories save production costs. Materials that can be recycled include polypropylene (PP) which is mainly used for packaging consumer and household goods, polystyrene (PS), polycarbonate (PC) and ABS.

- Machines for factory film waste

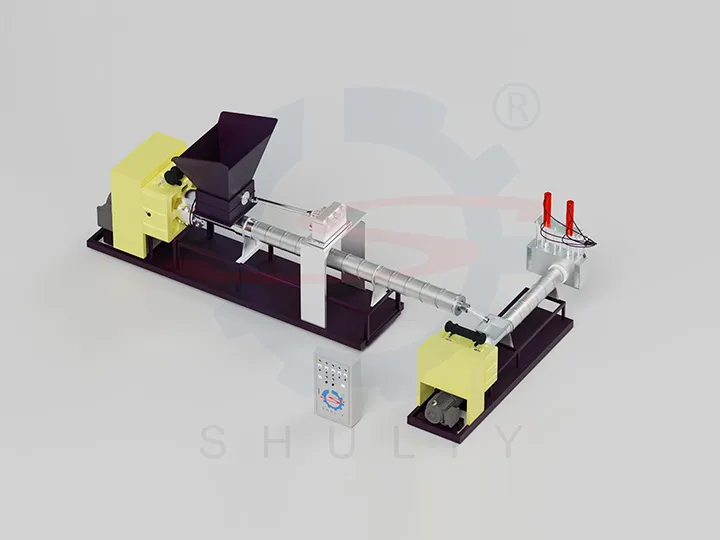

This two-stage recycling granulator effectively melts injection molding trimmings and factory waste. Your recycled pellets will be of the highest quality and productivity due to the integration of high-quality pelletizing screws, highly efficient electromagnetic heating methods, two die filtration and cooling cutting systems. If you’re looking for a recycling machine for your plant, the Shuliy can fulfill your needs.

- Want to find out more about this product: Rigid Shredder – Two-stage Recycling Machine

- Complete recycling solution: Pelletizing Line