Is Laminated Film Recyclable?

What is laminated film?

Laminated film is made by laminating multiple layers of materials. These materials include plastics, paper, foils, etc., and they are combined through laminating techniques to provide specific properties such as durability, protection, and aesthetics. The versatility of laminated films has led to their use in many industries.

Here we can set several examples:

- Food Packaging. Laminated films can be used in flexible packing, and provide excellent protection against moisture, oxidation and tearing, extending the shelf life of food products.

- Printing and book covers. The use of laminating films on prints and book covers enhances the gloss and abrasion resistance of the surface, making it more attractive and durable.

- Industrial Applications. The use of laminated films in protective clothing, insulation and composites provides specific functionality and protection.

Is laminated film recyclable?

The answer is yes, laminated film is recyclable and does not emit any toxic or harmful by-products when recycled. So what’s the solution to laminated film recycling?

- The first step of laminated film recycling is collection and sorting.

The first step in recycling laminated films is to collect and sort different types of used laminated films. Depending on the material, they can be categorized into plastic substrates, paper substrates and metal foil substrates (We can call it metalized films).

- The second step is cleaning and shredding.

Collected film scrap needs to be cleaned to remove surface dirt, grease and other contaminants. For printed films, ink residues on the surface also need to be removed.

(Want to learn more about washing product: Rinsing Tank)

After cleaning, the films need to be pulverized in a plastic shredder to turn them into small pieces or granules. This step can help with subsequent processing steps such as granulation.

(Know more about film shredder: Shuliy Plastic Shredder Machine)

- The third step is film granulation.

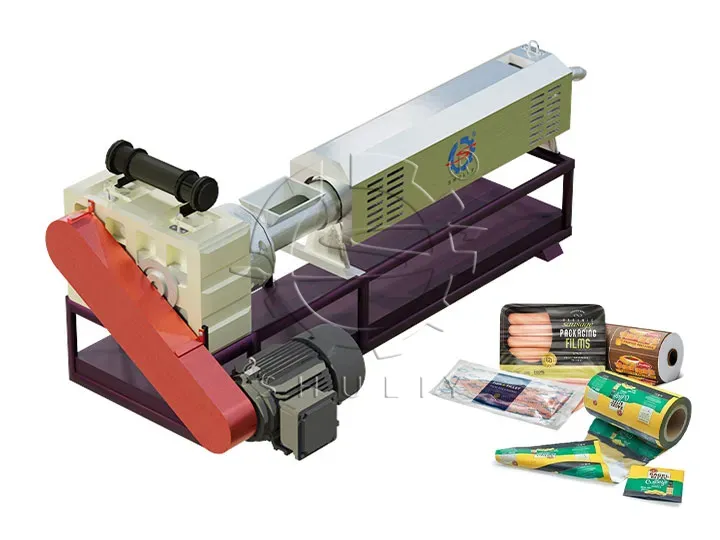

After shredding, the laminated film is passed through a plastic granulator for pelletizing. The pelletizing process involves heating and melting the film material, which is then passed through an extruder to form uniform pellets. These pellets can be used as raw material for the production of new plastic products.

The above steps are the essential process of laminated film recycling. Know more about Shuily film pelletizing line: One-stop Plastic Recycling Line

Something you need to pay attention

For some specialized materials, recycling plants require some additional processing.

For metalized films, due to the presence of a layer of metal (usually aluminum), special equipment may be required to separate the metal and plastic portions during the recycling process. The separated metal and plastic parts can be recycled separately.

Inks and coatings on fully printed films also require additional treatment during the recycling process, such as solvent cleaning or heat treatment, those processes can remove additional substances and enhance the final pellets’ quality.

Conclusion

Recycling laminated film through appropriate equipment and technology not only reduces environmental pollution but also realizes the reuse of resources and promotes the development of a circular economy.

If you want to know more about the solutions for recycling laminated film, please contact us, we will provide you with professional recycling equipment and technical support.