Semi-automatic Tire Recycling Plant for Rubber Powder Production

| Daily Capacity | 1-3tons per day |

| Motor Power | 30–150kW (depending on the model) |

| Steel Nylon Separation Efficiency | 99.2% |

| Gum Powder Size | 10-40 mesh (2.5-0.63mm) |

| Applicable diameter | less than 1200mm |

You can now ask our project managers for technical details

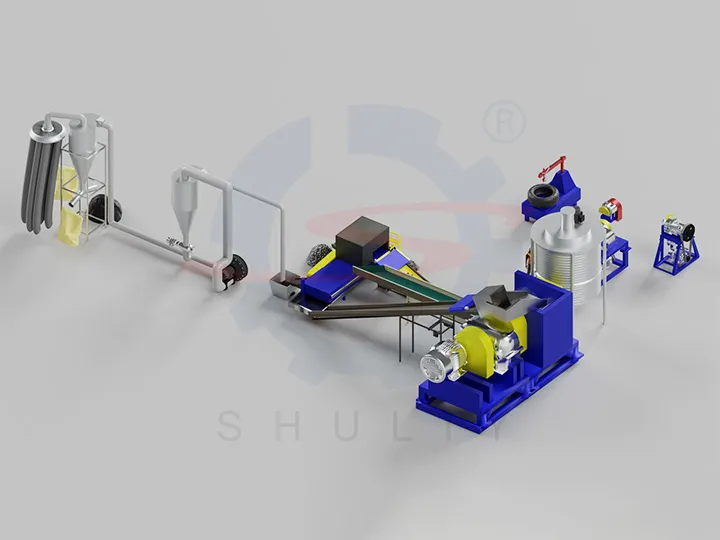

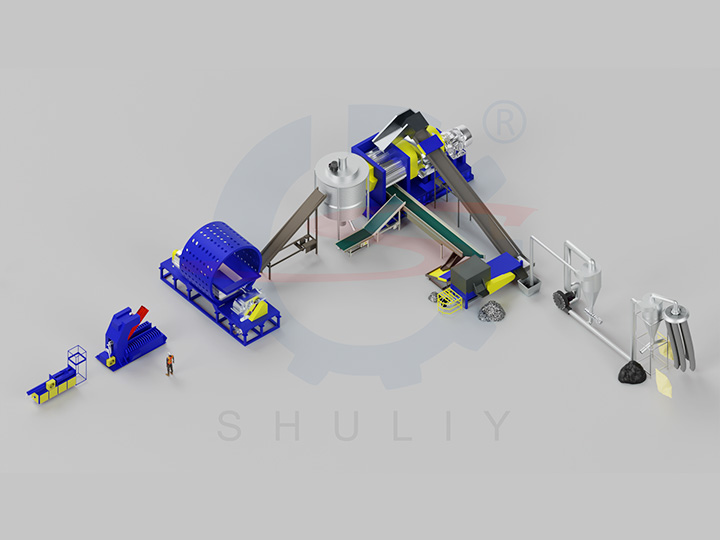

Our semi-automatic tire recycling plant is designed to process waste tires of various sizes into high-quality rubber powder, clean steel wire, and optional nylon fiber. This versatile tire recycling machine line includes a ring cutter, strip cutter, block cutter, bead wire remover, rubber powder mill, and an optional fiber separator. The process is engineered for maximum efficiency, reduced wear on key components, and optimized end-product purity, making it an ideal investment for recycling businesses worldwide.

rubber powder with different sizes

rubber powder with different sizes shredded rubber granules

shredded rubber granules

Rubber powder production process

The process begins with the tire recycling machine cutting the sidewalls to remove the steel bead rings. The tire body is then sliced into strips and blocks, which are easier to handle and feed into the next stage. The bead wire remover extracts the remaining steel wire, protecting the grinding equipment.

In the rubber powder production line, the rubber blocks are ground into fine powder (20–120 mesh), with magnetic separation ensuring the removal of any remaining metal. For nylon-reinforced tires, the optional fiber separator increases the rubber powder purity to 99%.

Tire recycling machines for the tire pretreatment

The tire bead cutter is the first step in the tire recycling process, designed to break the tire sidewall.

After bead removal, the tire strip cutter slices the remaining tire body into uniform strips. These strips are the right size for feeding into the block cutter

The tire block cutter reduces the tire strips into smaller, manageable blocks, making them suitable for feeding into the rubber shredders.

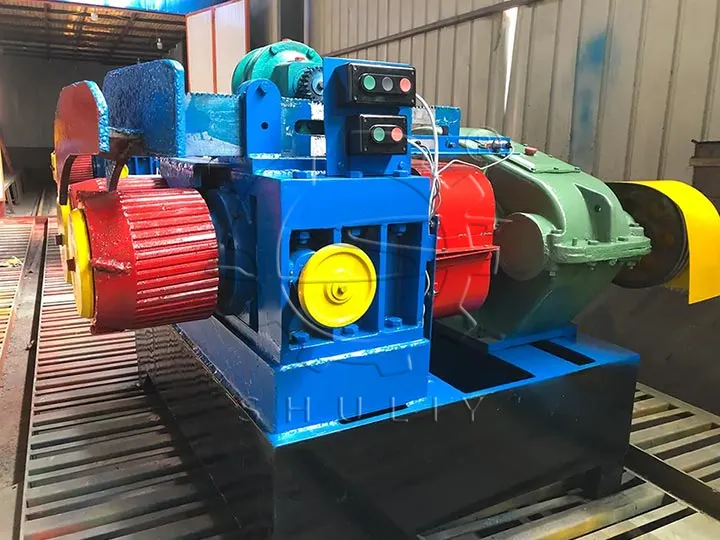

Key Equipment of the line: Rubber Grinding Machine

The core function of this tire grinder in the recycling line is to grind pre-processed rubber blocks into fine, high-value rubber powder.

Specifically, its function can be broken down into the following points:

- The tyre crusher machine processes rubber blocks that have already undergone pre-treatment (debeading, stripping, cutting) and have had the main steel bead wire removed.

- Using two high-speed, counter-rotating alloy rollers with special grooves, it subjects the incoming rubber blocks to intense squeezing, shearing, and grinding.

- Ultimately, it physically grinds these rubber blocks into rubber powder or granules, a raw material ready to be used in the manufacturing of new products like running tracks, floor tiles, and waterproofing membranes.

Highlight of Shuliy semi-automatic tire recycling plant

Our tire recycling plant is designed to balance efficiency, cost, and environmental performance:

- Flexible configuration – Machines can be customized for small-scale, medium-scale, or industrial production.

- High productivity – Even the smallest model can process up to 8000 kg of material per hour.

- Durability – Equipped with wear-resistant alloy blades and heavy-duty construction for long service life.

- Energy efficiency – Optimized motor systems reduce power consumption during the grinding process.

Turn Scrap Tires into Valuable Resources: Applications & Opportunities

Investing in our equipment opens up a diverse market for converting scrap tires into in-demand products. Here is the value you can create:

- High-Value Rubber Powder & Granules: This is your premium product, used to manufacture colorful running tracks, safe playground tiles, high-quality reclaimed rubber, and durable waterproofing membranes.

- High-Calorific Tire Derived Fuel (TDF): The shredded tire chunks are a clean, high-energy alternative fuel sought after by cement kilns, power plants, and industrial boilers.

- Direct Revenue from Scrap Steel: The separated and baled steel wire is a high-quality raw material for steel mills, ready for immediate sale and cash flow.

Applications of Rubber Powder

Rubber powder produced by our rubber powder production line is a high-value, versatile material with wide-ranging applications across multiple industries.

In the sports and leisure industry, fine rubber powder is widely used to create running track surfaces, playground flooring, and sports field infill, offering excellent shock absorption, slip resistance, and durability. In the construction sector, it is an essential additive for modified asphalt.

For the manufacturing industry, rubber powder can be processed into rubber mats, floor tiles, and molded products for both industrial and household use. It also plays a role in producing reclaimed rubber, which can be reintroduced into tire manufacturing or other rubber goods.

Additionally, the steel wire extracted during the recycling process can be sold to metal recyclers, while optional nylon fiber recovery provides another revenue stream for textile or reinforcement applications.