Plastic Granule Cutter for Strand Pelletizing

| Application | For plastic strand pelletizing |

| Model | SL-180, SL-220, SL-260 |

| Width of knives (mm) | 180, 220, 260 |

| Type of knives | Hob type |

| Related products | Plastic granulator, plastic washing machine, plastic crusher |

| Warranty | 12 months |

You can now ask our project managers for technical details

The plastic granule cutter is an indispensable auxiliary machine for the plastic granulating line. Shuliy plastic granule cutters have been exported to many countries in the world to support their plastic recycling businesses. The final plastic granules are of high quality and profitable profits, bringing our customers huge economic margins.

Plastic granule cutter introduction

The plastic granule cutter is used in a plastic pellet production line, cutting plastic perfectly at the end of the line. The granule cutter machine is suitable for PP, PE, HDPE, LDPE, ABS, PVC and other plastics. The long plastic strip will be cut by a rotary blade and a fixed blade. Then the large pieces of waste plastic into small pellets for subsequent processing or reuse. You can choose many different models with different voltages, which also can be customized.

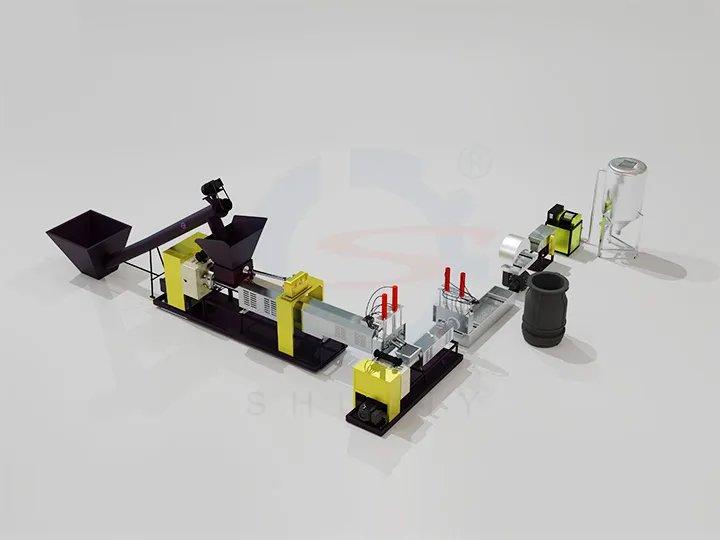

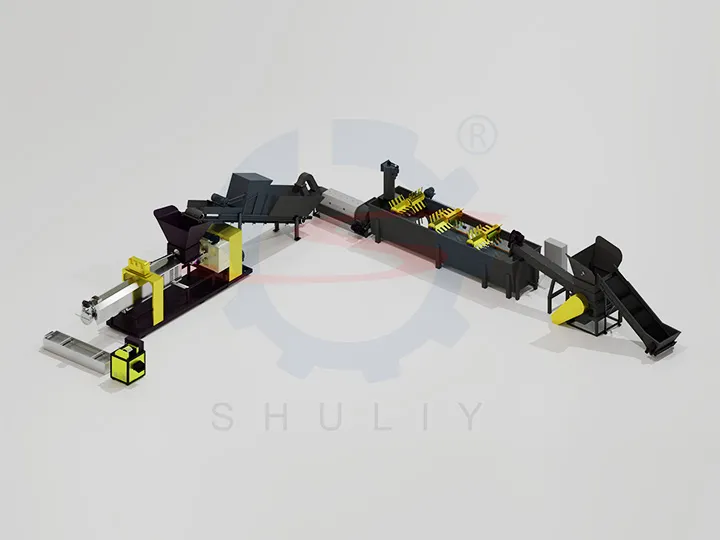

Plastic dana cutter machine display

Features of plastic granule cutter machine

- High efficiency: The plastic strip cutting machine adopts high-speed rotating blades, which can cut plastic materials quickly and achieve high-efficiency cutting.

- High degree of automation: plastic pellet cutting machine usually has an automatic control system, which can automatically complete the process of feeding, cutting and discharging, reducing manual intervention and improving production efficiency.

- Adjustable cutting size: The blade spacing and blade angle of the plastic strip cutting machine can be adjusted to achieve different size cutting effects to meet the needs of different customers.

- High safety: The plastic granule cutter usually has multiple safety protection measures, such as overload protection, emergency stop, etc., to ensure the safety of the plastic recycling plant operators.

- Simple maintenance: the machine uses alloy steel blades, no need to sharpen and polish the blades within a year. The plastic granule cutter machine structure is simple, and easy to maintain, replacing the blade and cleaning the machine are also relatively easy.

Parameters of plastic pellet cutting machine

The plastic pellet cutting machine is named by the width of the knives, for example, the model SL-260, the width of its knives is 260 mm. The following data is the basic parameters of the plastic granule cutter, feel free to leave your requirements on our website, and our sales manager will be happy to help you choose the most fittable model for you.

| Model | Power (kw) | Width of knives (mm) | Type of knives |

| SL-180 | 3 | 180 | Hob |

| SL-220 | 5.5 | 220 | Hob |

| SL-260 | 5.5 | 260 | Hob |

Related recycling line of plastic strip cutting machine

A plastic dana cutter is usually used in combination with other plastic recycling equipment to form a complete waste plastic pellet production line. For example, a plastic pellet cutting machine is usually used in conjunction with a washing machine and a plastic granulator. The plastic washing machine first cleans the waste plastic, and then the plastic granulator melts and granulates the plastic at high temperatures.

The plastic pellets need to be finally processed into small pellets by the plastic granule cutter. These recycled plastic pellets are the raw materials that can be used to produce plastic products.

The recycling line can also be equipped with plastic conveyors, plastic shredders, plastic drying machines, and other equipment to convey, shred, and dry the plastic to ensure the quality of plastic pellets. By using these machines together, waste plastics can be recycled efficiently and bring more profit for plastic pellet manufacturers.

Successful cases of plastic granule cutter

The plastic pellet cutter machine installed in Saudi Arabia

Plastic granule cutting machine shipped to Mozambique

Plastic granule cutter machine sent to Ethiopia

Plastic dana cutter shipped to Tanzania