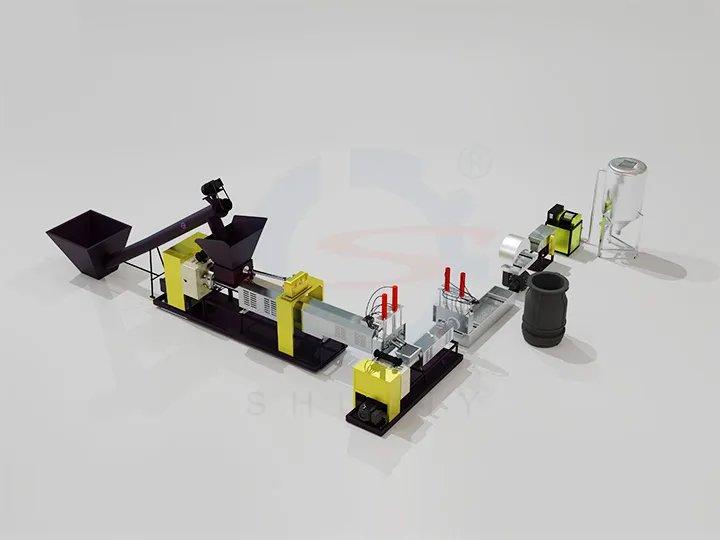

Plastic Film Washing Line

| Plastic Recycling Line Capacity | 100-500kg/h (can be customized) |

| Recycle Material | Film Scap, Film-on-roll, Woven bag, Soft irrigation pipe, Laminate film, Plastic food wraps, Agriculture films, Edge trim, Packaging bag, Bubble wrap, etc. |

| Core Equipment | Plastic rinsing tank, Crusher, Dryer |

| Final Product | Clean plastic film scrap |

| Application | Post-consumer Recycling |

| Warranty | 1 Year |

You can now ask our project managers for technical details

Shuliy’s high-efficiency plastic film washing line is designed for post-consumer waste. It can process PE polyethylene (HDPE, LDPE, LLDPE) and PP polypropylene waste material, such as used irrigation pipes, garbage bags, woven sacks, bubble wraps and laminated (muti-layered films. This film recycling system is equipped with crushing, cleaning and drying devices while producing high-cleanness film flakes at a productive rate.

Plastic film washing line working process

Plastic shredding machine: The first step of plastic washing pelletizing line is using a plastic shredding machine to cut plastic films into small pieces. The resulting plastic pieces from the plastic shredding machine are about 30mm-100mm in size.

Plastic rinsing tank: Plastic rinsing tank plays a key role. Plastic rinsing machines can remove dirt, grease, dust, residue, and other impurities from the surface of plastic through a series of water rinsing, so that the plastic debris can be treated more cleanly and purely. Clean plastic material results in a higher quality recycled product and less wear and damage to granulators and other recycling machines.

Centrifugal dewatering machine: Vertical centrifugal dewatering machine is a commonly used equipment for solid-liquid separation, and its main purpose is to dewater plastics suspended in liquids to the desired level of humidity or dryness. This centrifugal dewatering machine separates liquids and solids by centrifugal force, resulting in an efficient dewatering process.

Product silo: The silo is used to storage clean and dried plastic film pieces.

Plastic granulator (optional machine): Plastic granulator machine is one of the important recycling machines in the plastic film washing line, its main purpose is to heat and melt the recycled waste plastics and then extrude the plastic melt through the die. Recycled plastic pellets can be used as an alternative raw material for the manufacture of a wide range of plastic products, thus reducing the need for virgin plastic and lowering production costs.

Pellet packing machine (optional machine): The packing machine is used to package plastic granules into bags.

Additional pictures

Successful cases of plastic film washing line

Features of plastic film washing line

- Multifunctionality: the plastic film washing and pelletizing line can adapt to many types of waste plastics, including plastic woven bags, waste plastic film, plastic packaging bags, etc. It can meet the needs of all plastic recycling plants for plastic film recycling.

- High degree of automation: Plastic film washing line is usually equipped with an advanced automation control system, silo, and conveyor belt are installed with automatic control and discharging device, which reduces manual operation and improves recycling efficiency.

- Efficient cleaning: Plastic washing pelletizing line adopts a multi-stage cleaning process, which can effectively remove the dirt, oil, and other impurities on the surface of waste plastics and ensure the cleanliness and quality of waste plastics.

- Water recycling: To reduce the consumption of water resources, the plastic film washing line adopts a water recycling system to recycle the water in the cleaning process, which reduces the consumption of water.

- Flexible adjustment: Plastic film washing and pelletizing lines can usually be flexibly adjusted and customized according to the different needs of customers, the recycling machines can be adjusted for different types and specifications of waste plastics.

Inquiries for plastic film recycling

If you are interested in plastic film recycling machines, fill out the form in the lower right corner.

Our project manager will contact you as soon as possible and send you a recycling machine quotation.