A Startup’s Guide to the 150kg/h Small Scale Plastic Granulator

Starting a plastic recycling business is an exciting venture with huge potential for both profit and positive environmental impact. But the first major decision—choosing your primary equipment—can be daunting. The temptation might be to get the biggest machine you can afford, but the smartest move is often to start with a machine that perfectly matches your initial scale.

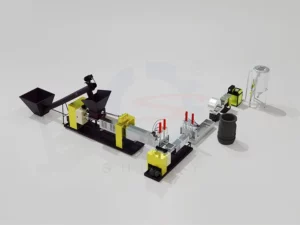

This is where a small scale plastic granulator shines. Specifically, this guide will explore why our Type 105, a robust 150kg/h plastic granulator, is the ideal granulator for startup operations.

The Startup Sweet Spot: Balancing Investment and Recycling Machine ROI

For a new venture, cash flow is king. The goal is to begin generating revenue as quickly as possible without taking on excessive debt or overwhelming operational costs. A 150kg/h capacity hits the perfect sweet spot for profitable small scale recycling.

- Sufficient Output: It’s powerful enough to process a significant amount of scrap per day, allowing you to produce enough pellets to build a customer base and generate consistent income.

- Manageable Investment: As an entry-level recycling machine, it represents a more affordable pelletizer machine. This lower initial cost means a faster path to profitability and a healthier recycling machine ROI.

A Small Scale Plastic Granulator with a Professional Core

“Small scale” should refer to the size and output, not the quality. A common mistake is choosing a cheap, poorly built machine that leads to constant downtime. Our Type 105 granulator is designed to be a professional recycling machine for small business operators who demand reliability. Let’s look at the specifications:

| Specification | Type 105 |

|---|---|

| Screw diameter | 105mm |

| Main motor power | 18.5kw |

| Size (L*W*H, m) | 2.4*0.7*0.7 |

| Output | 150KG/H |

Here’s what these numbers mean for you:

- Efficient Power: This 18.5kw plastic granulator is designed for efficiency. The motor provides ample power for its 105mm screw without consuming excessive electricity, keeping your daily operational costs low.

- Compact Footprint: At just 2.4 meters long, this is a truly compact plastic granulator. It can fit into smaller workshops or garages, saving you money on rent and making setup much simpler.

- Professional Build: Most importantly, this machine is not a “hobby” machine. It features the same core engineering as our larger industrial models, including a hardened 38CrMoAl screw and a robust hard-gear reducer. It’s a simple plastic granulator to operate, but it’s built for serious work.

Planning for Growth with Your First Machine

Your first machine should be a stepping stone, not a dead end. By starting with a reliable 150kg/h unit, you can master the process, whether you’re creating a small plastic film recycling line or processing rigid plastics. As your business grows and your material supply increases, you will have the capital and experience to confidently scale up to a larger machine.

Choosing the right small scale plastic granulator is about making a smart, strategic investment in your future. Our Type 105 model provides the perfect combination of affordability, reliability, and professional performance to get your venture off the ground and on the path to success.

Ready to take the first step in your recycling journey? Explore the full technical details of our complete range of plastic granulators.