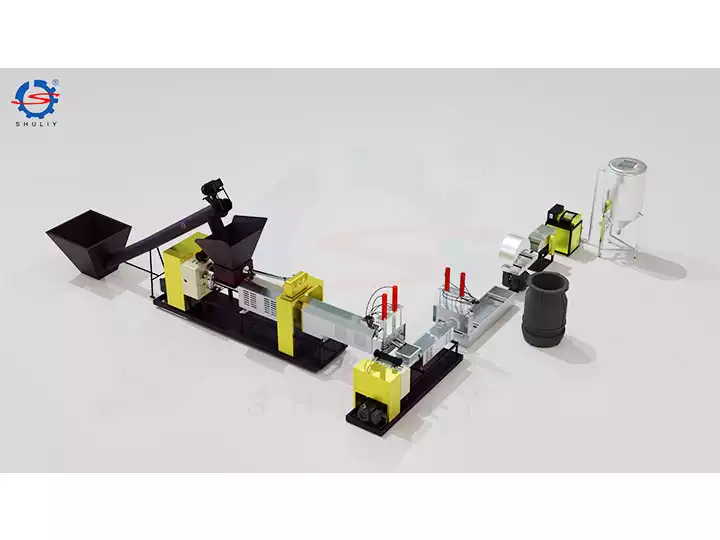

Shuliy Simple Three-Stage Pelletizing Solution for 500KG/H Output

For professional post-consumer recyclers, outputs of 500 kg/h are more common. For this high-output granulation, more continuous and stable filters are needed to reduce the granulation interruption process, reduce the number of screen changes and improve the overall granulation efficiency. This is a key factor.

Shuliy Focuses on Improving the Pellet Quality of Post-Consumer Scrap

Most recycling solutions on the market today are single and double-stage pelletizing, these are more suited to production volumes of less than 500kg/h, for larger volumes Shuliy recommends three-stage pelletizing.

The combination of the Shuliy 3-stage extruder pelletizer and the hydraulic die head filtration system provides a more consistent and efficient solution for the professional recycler. While most two-stage pelletizing systems on the market require screen changes every half hour, the Shuliy three-stage extruder extends the screen change time to every four hours, greatly improving pelletizing continuity. In addition, multiple filtrations result in higher-quality plastic pellets with fewer impurities, leading to higher profit margins.

Advantages of Shuliy Three-Stage Pelletizing Machine

- The use of hydraulic double die heads ensures continuous discharge and increased productivity

Compared to ordinary die heads in the market, Shuliy hydraulic die head filtration does not need to stop when changing the screen, one only needs to simply move the valve can be realized on one side to change the screen, the other end can take over the work, only one operator can change the screen, less labor costs.

- Triple filtration ensures clean material and improves plastic pellet quality

Inside the die head of the pelletizing machine, there are 3 or 4 filters, two 80 mesh filters in the outer layer and 60 mesh filters in the middle, which effectively filter out the dirt inside the plastic.