EPS Pelletizing Machine for Plastic Foam Recycling

| Model | 220 (Double Reducer) |

| Capacity (KG/H) | 150-175 |

| Main Motor (KW) | 15 |

| Model | 270 (Double Reducer) |

| Capacity (KG/H) | 200-225 |

| Main Motor (KW) | 18.5 |

You can now ask our project managers for technical details

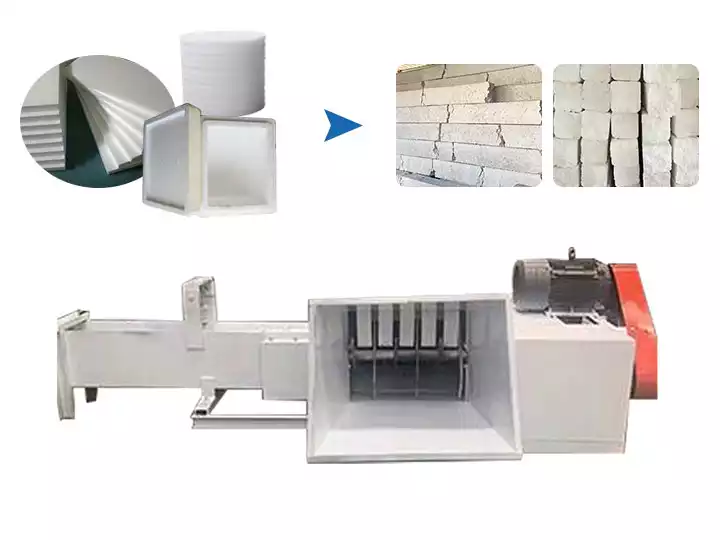

EPS pelletizing machine is a professional equipment in the plastic foam recycling industry, which is specifically for waste styrofoam (polystyrene). The styrofoam granulator structure is compact and reasonable, and the investment cost is low, which is the ideal EPS recycling machine.

Applications of EPS granulator

The polystyrene recycling machine can be matched with a foam shredder and pellet cutting machine, those are the basic equipment of the plastic foam recycling line. The recycling line can crush, extrude, cool, and granulate the waste foam fast food boxes, foam fresh boxes, insulation materials, packaging foam for furniture, etc. so that the waste foam becomes the best-selling recycled EPS granules in the market. The foam granulator machine meets the high standard pelletizing requirements of EPS ultra-low density foam plastic.

Final product of EPS foam pelletizing machine

After recycling the final pellets are EPS recycled pellets, they have a hard texture, uniform size, high gloss, and a wide range of uses. The main uses include building exterior insulation panels, transparent parts of public buildings, optical instruments, transparent models and so on. The manufacturers with high demand are mainly external wall insulation wall factories, photo frame factories, and billboard factories.

Styrofoam granulator structures

In general, the styrofoam recycling machine is often used in combination with a foam crusher and a cooling pool. The styrofoam shredder is easier to feed by using horizontally. The EPS granulator consists of a submachine, and this combination makes the plastic melt more thoroughly.

Advantages of EPS recycling machine

- Shuliy manufacturer has a complete range of plastic recycling technology and reliable quality. We also have a perfect after-sales service. If you are a novice, you can buy with confidence, our professional technicians will explain how to operate.

- The plastic EPS granulator is made of carbon structure lead steel, durable, and not easy to deformation which has a high capacity and a long service life.

- The set of EPS pelletizing machines have perfect supporting facilities and covers an area of small and high-quality finished products.

- The foam granulator machine makes full use of the high-pressure friction heating, and automatic heating production, which can avoid heating continuous heating and save more energy-saving power.

EPS foam pelletizing machine parameters

The EPS granulator has six models, customers can choose one according to his demands and capacity.

| Model | Capacity (KG/H) | Main Motor (KW) |

| 220 (Double Reducer) | 150-175 | 15 |

| 270 (Double Reducer) | 200-225 | 18.5 |

| 220 (Single Reducer) | 150-175 | 15 |

| 270 (Single Reducer) | 200-225 | 18.5 |

| 320 (Double Reducer) | 275-300 | 18.5 |

| 350 (Double Reducer) | 325-375 | 22 |

EPS recycling machine plant display

Maintenance of EPS pelletizing machine

Any machine needs regular maintenance, and an EPS pelletizing machine is no exception. After a period of use of the pellet mill, some customers find that the foam recycling machine rotation is also not as flexible as before. The cause of this problem is relatively simple. Machine lack of oil or chassis dust caused by more. We can check the work of the rollers every six months, grease, and timely replacement of worn or damaged bearings.

Operators should clean the oil cup, oil tank, pipeline, and filter after 500 hours of production time, then add new filter oil. Clean the dust and dirt in the electric control box once every quarter or half a year, check the lubricant quantity of the oil tank, and replenish the lubricant quantity in time.

Services of Shuliy Machinery EPS granulator

- We offer a free but professional product consultation service. Normally, our sales consultants will reply within 24 hours.

- You are warmly welcome to visit our factory to see the plastic EPS foam recycling machine. If you are unable to visit the factory, our staff will send you pictures and videos, please feel free to contact us.

- After-sales engineers are available to assist you with the installation of your machine. Once the machine arrives, our engineers will be online to help you set up and debug the machine.

- All of Shuliy Machinery’s EPS recycling machines are covered by a one-year free warranty. Please feel free to contact us.