Advantages of LDPE Stretch Film Granulation Line

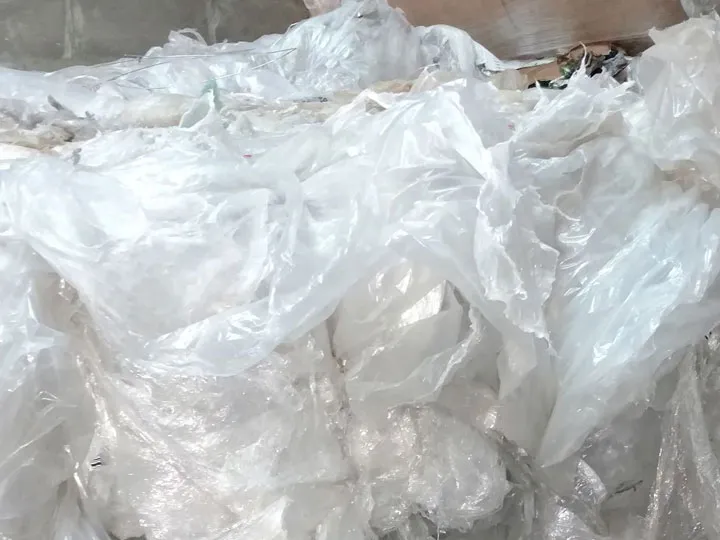

Low-density polyethylene (LDPE) films, such as plastic bags, stretch films and packaging materials, have become integral to our daily lives. In order to minimize the negative impact on the environment, LDPE film stretch granulation is becoming increasingly important. The following is an introduction to the granulation process of LDPE film and the required plastic recycling machines.

LDPE plastic film recycling process

Collection and Sorting: First, waste LDPE stretch film needs to be recycled. This can be done through regular recycling programs or waste sorting centers. The material needs to be sorted to ensure purity.

Washing and shredding: The film may be contaminated and therefore needs to be washed. This step usually involves placing the film in a washing tank to remove dirt and impurities. Next, the film needs to be cut or crushed by a plastic crusher machine into smaller particles for further processing.

Dewatering: Wet LDPE pellets need to be passed through a dewatering machine to remove excess water and ensure pellet quality.

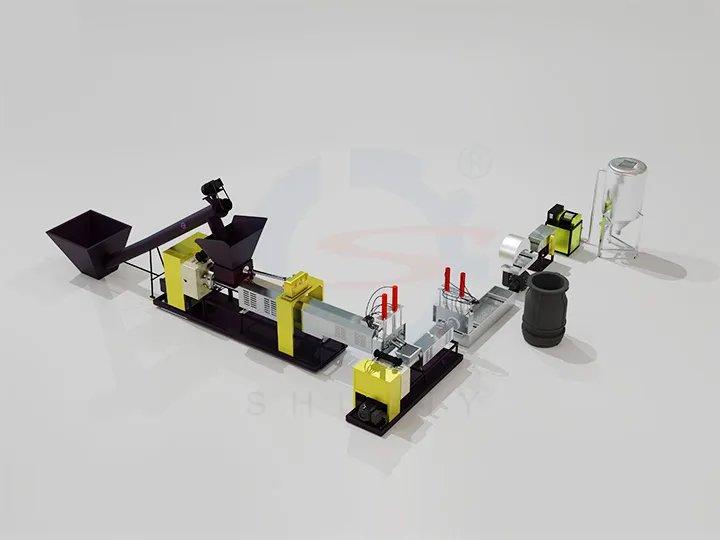

Granulating: The plastic granulator machine is the key equipment that converts the cleaned and dewatered LDPE pellets into recycled pellets. This step usually involves heating and extrusion.

Cooling and Cutting: Once the plastic granulating is complete, the pellets need to be cooled in a cooling tank and then cut into desired-size pellets through a cutting machine.

Advantage of LDPE stretch film granulation line

- High Production Capacity: Our recycling machines for LDPE films have a high production capacity from 200kg/h to 2000kg/h, capable of swiftly processing large quantities of LDPE film. This helps enhance recycling efficiency, reduce production time, and lower labor costs.

- Quality Control: Our LDPE stretch film granulation line is manufactured with precision and control technology to ensure consistent quality and specifications of the recycled pellets. This is crucial for producing high-quality recycled plastic products.

- Customer Customization: We offer machine customization services, allowing adjustments to the machine’s specifications and performance according to customer requirements. This means customers can get recycling machines that meet their specific needs.

- Reliable After-Sales Support: We provide comprehensive after-sales support, including training, installation, technical assistance, and spare parts supply, ensuring the continued high performance of the machines.

LDPE stretch film granulation line conclusion

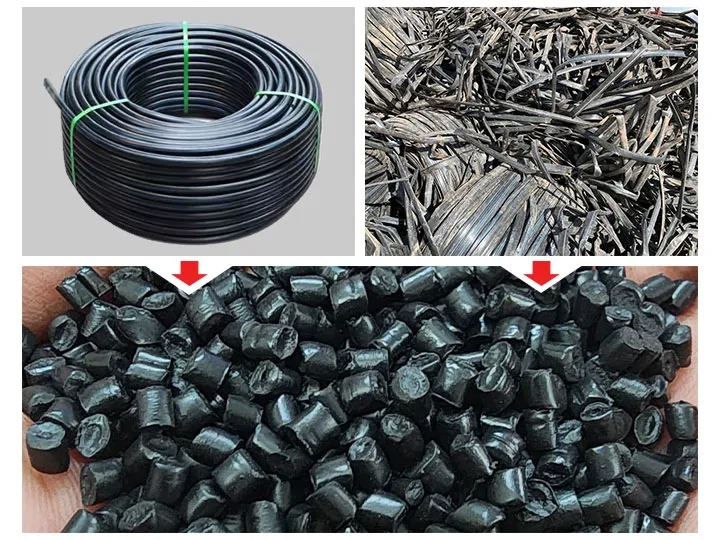

Through the synergistic action of this range of recycling machines, LDPE film can be obtained as high-quality recycled pellets of controlled color and size for the production of new plastic products. LDPE stretch film granulation line helps to reduce the negative environmental impact of plastic waste and promotes a sustainable plastic circular economy.