Hard Plastics vs. Soft Films: Understanding the Unique Challenges in flexible Plastic Recycling

In the recycling industry, a common mistake is to assume that “plastic is plastic.” This oversimplification leads to significant operational failures, equipment damage, and low-quality output. The reality is that the physical properties of plastic waste dictate the entire recycling process. Nowhere is this more evident than in the comparison of hard plastic vs. soft plastic recycling.

Understanding the fundamental differences between rigid materials (like PET bottles and HDPE drums) and flexible films (like LDPE packaging film) is the first step toward designing an efficient and profitable operation.

The Challenge of Rigids: Brute Force and Abrasion Resistance

Recycling hard plastics is a matter of overcoming their structure with brute force.

- Key Challenge: Their rigidity, thickness, and often abrasive nature (due to fillers or contaminants) require immense impact force to fracture. The main PET bottle recycling challenges, for example, involve dealing with thick walls and harder cap materials.

- Processing Requirement: The process must be designed for high-impact shattering. This requires a heavy-duty crusher for hard plastics with a high-mass rotor, robust construction, and blades made from hardened tool steel to resist wear and chipping when crushing HDPE drums or other thick-walled items. This is the core principle of a well-designed hard plastic recycling line.

The Unique Challenges of Flexible Plastic Recycling

Flexible films present a far more complex set of problems that cannot be solved with brute force alone. This is where many recycling operations fail.

1. Low Bulk Density and Feeding Issues

The most immediate problem with films is their low bulk density. They are light and fluffy, like feeding feathers into a machine. This causes inconsistent feeding, leading to the machine running empty frequently, which wastes energy and reduces throughput.

2. Elasticity and the Wrapping Phenomenon

This is the single most critical challenge in flexible plastic recycling. Unlike rigid plastics that shatter on impact, films are designed to stretch and resist tearing.

What Happens Inside the Crusher? When a standard crusher’s flat blades strike a plastic film, the film doesn’t break. Instead, it stretches and wraps itself tightly around the rotor and knives. This phenomenon, known as plastic film wrapping around crusher rotor, quickly builds up, causing the machine to overheat, jam, and eventually seize. Answering the common question, “why is my plastic crusher jamming with film?” almost always points to this wrapping issue.

3. Difficult to Wash Effectively

Dirt and moisture get trapped in the folds and layers of bundled films, making them difficult to clean thoroughly in a standard washing process.

Engineered Solutions: A Tale of Two Processes

Because the challenges are different, the solutions must be purpose-built. You cannot effectively process both streams with the exact same equipment setup.

Solutions for Hard Plastics:

The solution is straightforward: power and durability. The design of an effective plastic crusher for rigids focuses on a heavy rotor to provide inertia, thick steel housing, and claw-type knives for an aggressive tearing and crushing action.

Solutions for Flexible Plastic Recycling:

Solving the film problem requires smarter engineering, not just more power.

Wet Granulation: This is a key process. The equipment for recycling plastic film often includes a water inlet in the crushing chamber. Wet granulation for plastic film provides three distinct advantages:

- Adds Mass: Water wets the film, making it heavier and preventing it from floating above the rotor.

- Cools the System: The friction from processing film can cause it to melt and become sticky. Water acts as a coolant, preventing this.

- Pre-Washes: It begins the plastic film washing process right in the crusher, removing surface dirt.

V-Type Rotor Design: Instead of a blunt, impactful strike, a V-type (or scissor-cut) rotor creates a progressive cutting action from the outside in. This clean shear is far more effective at cutting the film rather than stretching it, directly preventing the wrapping issue.

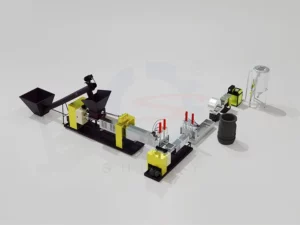

Downstream Density Increase: After granulation, the low-density flakes are often fed into a film agglomerator or squeezer to increase their density before being processed by a plastic pelletizing machine. This entire workflow is optimized in a complete plastic film recycling line.

| Feature | Hard Plastic (Rigid) Recycling | Flexible Plastic Recycling |

|---|---|---|

| Primary Challenge | Brittleness, Thickness | Elasticity, Low Density |

| Cutting Action | High-Impact Shattering/Crushing | High-Speed Shearing/Cutting |

| Rotor Design | Claw or Flat Blade | V-Type (Scissor Cut) |

| Water Injection | Optional, not essential | Highly Recommended |

| Key Failure Mode | Blade Wear, Motor Overload | Rotor Wrapping & Jamming |

Ultimately, understanding the unique properties of your plastic waste is the key to profitability. The process must be tailored to the material, and the equipment must be engineered for the process. Attempting to use a one-size-fits-all approach is a recipe for inefficiency and failure.