Hot Melter VS Cold Polystyrene Densifier for Sale

Cold polystyrene compactor

Styrofoam/Polystyrene foam compactor is a kind of equipment used to process waste foam (such as EPS, EPE), specially designed to compress the volume so that the density of the foam is increased, which is convenient for storage and transportation.

- Feeding method: the foam cold press compactor can be fed in two ways: top feeding and side feeding. Side feeding is generally used in horizontal cold presses and is designed to facilitate manual feeding.

- Crushing process: Loose foam material is put into the hopper, which is cut and crushed by the crushing equipment to become smaller pieces. The crushed foam is then pushed by the screw to the compaction chamber.

- Compression process: When the compaction chamber is filled with foam pieces, the screw stops rotating and the hydraulic plunger starts moving in the compaction chamber to compress the air out of the foam. This process dramatically reduces the volume of the foam, creating a high density block material.

- Cold compaction equipment for styrofoam/polystyrene foam can typically reduce the volume of foam material to 60:1, meaning that 60 times the original volume of the foam material can be compressed into a small volume block.

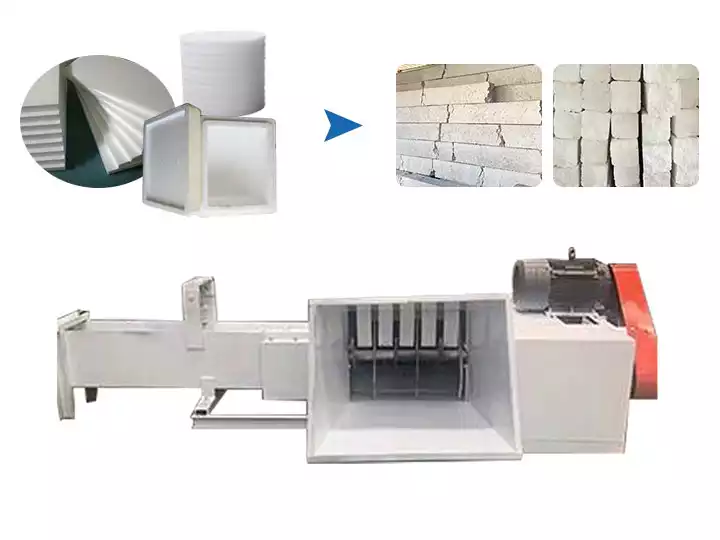

Plastic hot melter densifier

The Hot Melt Densifier in the Foam Recycling Machine is designed for the recycling of foam (e.g. EPS, EPE, XPS, etc.). It top feeds through a hopper type inlet, handles loose foam and compresses it to reduce its volume.

- The foam is put into the hopper of the densifier and enters through the inlet.

- Crushing process: The loose foam is shredded into smaller pieces by a system of blades.

- Screw conveying: the chopped foam will fall into the screw system, which rotates to convey the foam to the heating unit.

- Heating and melting: The screw pushes the foam into the heated melting zone, where the foam melts at high temperatures and is greatly compressed in volume.

- Volume reduction: The Hot Melt Densifier reduces the volume of the foam in a ratio of 90:1, i.e. the density of the processed foam increases and the volume is significantly reduced, which facilitates subsequent transportation and reprocessing.

At Shuliy Machinery, we handle both hot melter and cold compaction foam densifiers. Each type utilizes different technology and each type offers unique advantages and benefits depending on your application.

Let’s talk through your project and recycle foam and then we can provide you the best and most cost-effective recycling solution.