EPE/EPS Polystrene Styrofoam Compactor

| Compactor application | EPE, EPS(styrofoam/polystrene) |

| Compression ratio | 50:1 |

| Compactor output | 100-250kg/h |

| Warranty | 1 year |

You can now ask our project managers for technical details

Styrofoam compactor is a specialized equipment used to process waste foam materials, and many plastic recycling plants use this machine to initially process foam waste. Below are some of the advantages of the foam cold press and the advantages of using this machine for recycling plants.

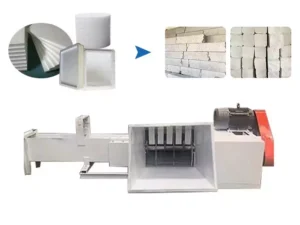

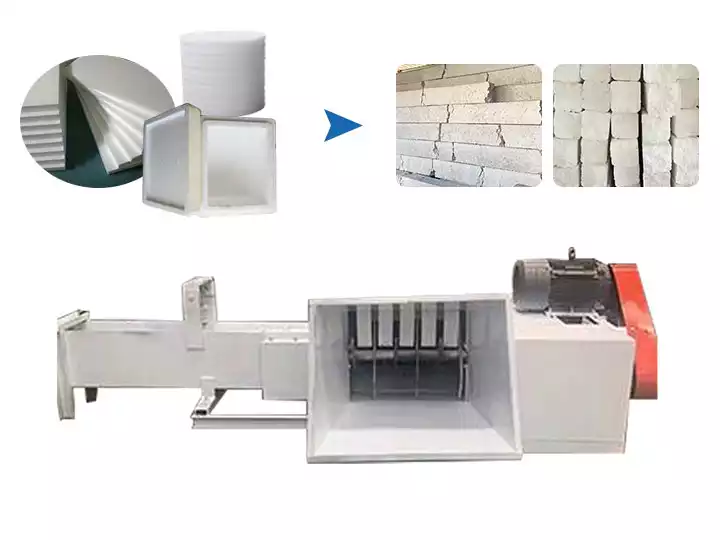

Raw materials & end products of EPS foam cold pressing styrofoam compactor

Foam is a kind of lightweight, porous material also known as white foam or styrofoam. It is commonly used in packaging materials, building insulation, and insulation foam. Our EPS foam cold pressing styrofoam compactor can handle all foam waste on the market.

Working principle of plastic foam compactor

Feed: Waste foam material is first introduced into the plastic foam compactor through the feed system. Before entering the plastic foam compactor, the foam material usually has to pass through a crushing port. The purpose of this step is to pulverize the foam into smaller pieces to make it easier for subsequent processing.

Pre-compression: The foam material enters a pre-compression area where the material is compressed into a preliminary shape to reduce its volume.

Main Press: After pre-compression, the foam material enters the main press area. Here, a hydraulic system or other pressure mechanism applies more pressure to the material, further compressing it into a tighter, denser block.

Advantages of using foam polystyrene compactor

Efficient compression: Polystyrene compactor adopts efficient cold pressing technology, which can quickly and efficiently compress the large volume of waste foam material into compact blocks, reducing the volume and making it easy to store and transport.

Space saving: By compressing waste foam into high-density blocks, the polystyrene compactor saves a lot of storage space. This is a very important advantage for recycling plants, especially those facing limited storage space.

Improved transportation efficiency: Compressed foam blocks are easier to load and transport, thus improving logistical efficiency. This lowers transportation costs and reduces the need for transportation resources.

Improvement of environmental image: The use of foam cold presses helps foam recycling plants to improve their environmental image. Through efficient and energy-saving waste treatment, manufacturers are able to demonstrate their commitment to environmental protection and sustainable development, and enhance their corporate image.