Advantages of double stage plastic granulating machine

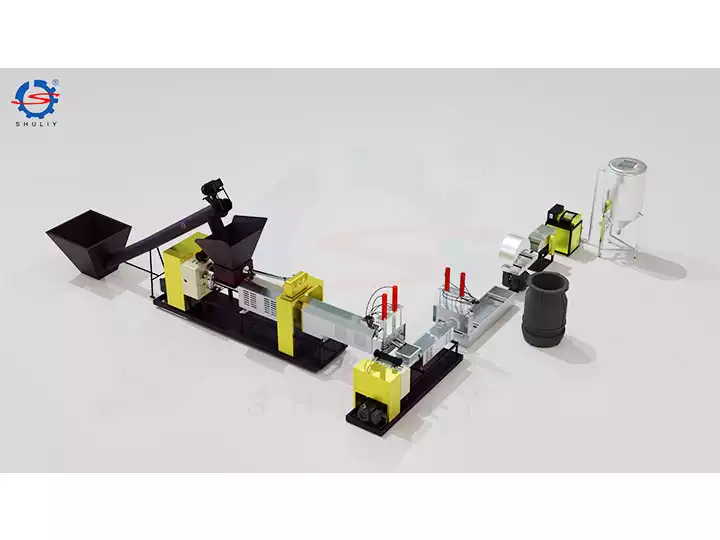

Double stage plastic granulating machine is a kind of equipment commonly used in the plastic recycling industry, many plastic recycling factories choose double-stage granulators, and this article introduces the main features and advantages of double-stage granulators.

Why do you need a double stage plastic granulating machine?

Efficient capacity: Due to the two-stage processing, the double-stage pelletizer usually has a higher capacity and can process from 500 kg to 2 tons of raw material. It is the first choice for large-scale plastics recycling plants.

Versatility: The double stage plastic granulating machine is suitable for a wide range of plastic raw materials, including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), etc. This versatility makes it ideal for processing a wide range of different plastics. This versatility makes it ideal for processing different types of plastics.

Better Pellet Quality: With two separate stages, double stage plastic granulating machine typically provide a more uniform, consistent pellet quality. This is important for applications where pellet quality is critical.

Reduced Energy Consumption: Despite the complexity of the equipment itself, a dual-stage pelletizer can potentially consume less energy per unit of capacity due to the ability to control and utilize the energy more efficiently in both stages, resulting in energy and cost savings for the recycling plant.

Highly customizable: double stage plastic granulating machines can often be customized to suit specific customer needs for different types and shapes of raw materials. Examples include the heating method and screw length of the plastic pelletizer.

Get your own plastic granulator machine right away!

If you are a company looking for an advanced plastic pellet production line, we strongly encourage you to contact us. Our team of professionals will provide you with the best design for your needs, and we can offer customized solutions no matter the size of your recycling plant.