Heavy-Duty vs. Small-Scale: Sizing Your Industrial Plastic Grinder for Maximum Efficiency

Selecting an industrial plastic grinder is one of the most critical decisions in establishing or upgrading a plastics recycling operation. The choice is not simply about buying the biggest or most powerful machine; it’s about precision-matching the equipment to your specific needs. An incorrectly sized machine is a constant source of inefficiency, whether it’s a low throughput plastic granulator creating bottlenecks or an oversized machine wasting energy and capital.

This guide provides the key plastic crusher selection criteria to help you answer the fundamental question: “what size plastic crusher do I need?” We’ll compare the roles of small-scale grinders and true heavy-duty machines to ensure you achieve maximum efficiency.

The Case for Small-Scale Grinders: Precision and Proximity

A small scale plastic granulator is the ideal solution for specific, targeted applications. It is not designed for high-volume, continuous recycling, but excels in other areas.

Best suited for:

- In-House Scrap Grinding: For injection molding or blow molding facilities, a small grinder placed beside the production machine can immediately process runners, sprues, and rejected parts. This creates a closed-loop system, reducing waste and material costs.

- Small Business & Start-ups: A plastic crusher for small business offers a lower initial investment, a smaller footprint, and reduced power requirements, making it an accessible entry point into the recycling market.

- Lab-Scale and R&D: A lab-scale plastic grinder is essential for testing the recyclability of new materials or creating small batches for product development.

The Need for a Heavy-Duty Industrial Plastic Grinder

When your operation moves to production scale plastic granulation, the definition of “capable” changes dramatically. A heavy duty plastic crusher is defined not just by its size, but by its construction, power, and durability, designed for continuous, demanding work.

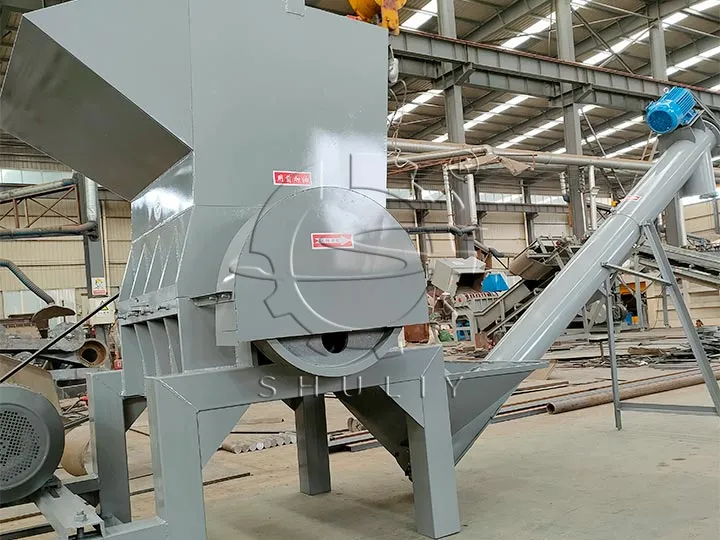

Let’s examine the specifications of a real-world heavy-duty 1000-type model designed for crushing large, thick-walled items like chemical drums:

- Robust Construction: The machine’s frame is built from 30mm thick steel plates. This massive construction absorbs vibration and withstands the immense shock loads of crushing dense materials.

- Core Strength: It features a solid 140mm diameter main shaft, providing the structural integrity needed to prevent flexing or failure under high torque.

- Raw Power: A 55KW motor power (kW) with a star-delta starter delivers the consistent force required to process tough materials without the risk of a crusher motor overloading.

- Maintenance & Safety: A hydraulic opening system allows the crushing chamber to be opened effortlessly in minutes. This is a critical feature for safe and fast blade changes, screen cleaning, and clearing the rare but inevitable jam, drastically reducing downtime.

A machine with these specifications is the only viable choice for a high capacity plastic crusher for a recycling plant that processes a continuous stream of challenging materials.

How to Calculate Your Needs: 3 Key Sizing Criteria

Sizing your industrial plastic grinder is a technical process. Use these three criteria as your guide:

1. Material Type, Size, and Form:

What are you processing? Large, hollow HDPE drums require a large chamber opening and high-impact force. Tangled LDPE film requires a different rotor design and benefits from a wet process in a plastic film recycling line. Thick-walled PVC pipes require immense shear force. Your material dictates the machine’s fundamental design.

2. Required Throughput (kg/h):

Be realistic about your current and future needs. A plastic crusher’s capacity (kg/h) is its most important metric.

- For outputs in the 600-800 kg/h range, a model like our SLSP-600 is a highly efficient choice.

- For a true 1000 kg/h plastic granulator requirement or more, you must step up to a heavy-duty model like the SLSP-1000. Always plan for 20-30% future growth to avoid creating a bottleneck later.

3. Operational Scale:

Will you operate 8 hours a day, or 24/7? Continuous operation demands a heavy-duty build quality, superior bearings, and features like the hydraulic opening system to minimize maintenance downtime.

The Hidden Costs of a Mismatch

Choosing incorrectly has direct financial consequences that go beyond the initial cost of an industrial plastic crusher.

- An Undersized Machine: Will lead to a plastic crusher constantly jamming, frequent motor overloads, and an inability to meet production targets. The operational stress will also lead to premature wear and failure.

- An Oversized Machine: Represents a poor plastic grinder return on investment (ROI). You suffer from a high initial capital cost and the energy inefficiency of an oversized crusher, as the large motor consumes significant power even when under-utilized.

The goal is to find the sweet spot where the machine is powerful enough for your toughest material but sized correctly for your average daily throughput. This ensures every kilowatt of energy is used effectively, turning waste into valuable flakes ready for a plastic pelletizing machine.

Whether you are processing hard plastics in a hard plastic recycling line or need a general-purpose plastic crusher, a proper sizing assessment is the first step toward a profitable operation.