Plastic Foam Pelletizing Line for Polystyrene Recycling

| Capacity (kg/h) | 100-500 |

| Raw Materials | EPS, EPS Foam |

| Core Equipment | Crusher, Granulator |

| Machine Color | White, Red (Support Customization) |

| Brand Name | Shuliy Machinery |

| Warranty | 12 Months |

| After Warranty Service | Video Technical Support, Online Support, Field Maintenance and Repair Service |

You can now ask our project managers for technical details

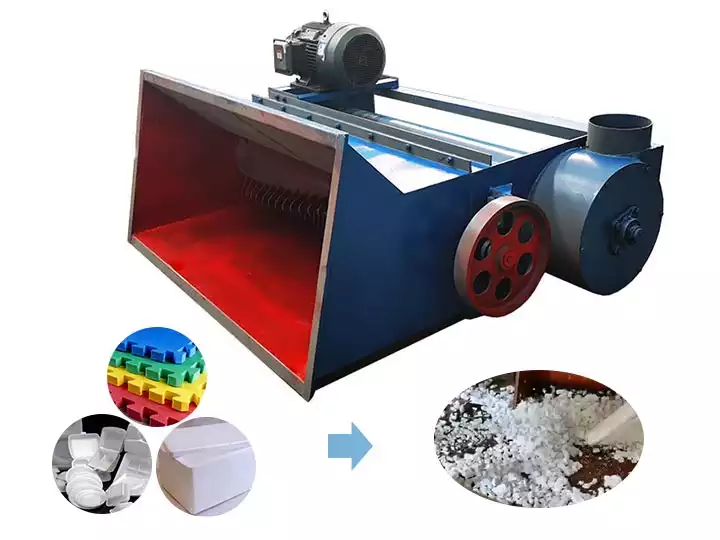

Shuliy plastic foam pelletizing line mainly copes with waste plastic foams, the waste plastics will be crushed and then turned into small plastic pellets, which can be reused as packaging materials, insulation, and other materials. The most important equipment for EPS recycling machines is granulators, which will melt and extrude pellets.

What are the waste EPS and EPE materials?

People in daily life everywhere and plastic products in contact, it has become one of the indispensable materials for people’s life and economic development. With the continuous development and application of plastics, EPE and EPS (styrofoam/polystyrene) have been widely used in packaging and filling materials.

EPE pearl cotton foam is a new type of plastic product material, widely used in gift packaging, hardware products, daily necessities, and other product packaging. Expanded Polystyrene, referred to as EPS, is a light polymer. Such as foam fast food boxes, foam packaging boxes, insulation materials, refrigerator outer packaging foam, and other white foam garbage.

Process of plastic foam pelletizing line

The collected waste plastic foam will be first shredded by a styrofoam shredder, and then melted and extruded by a EPS granulator.

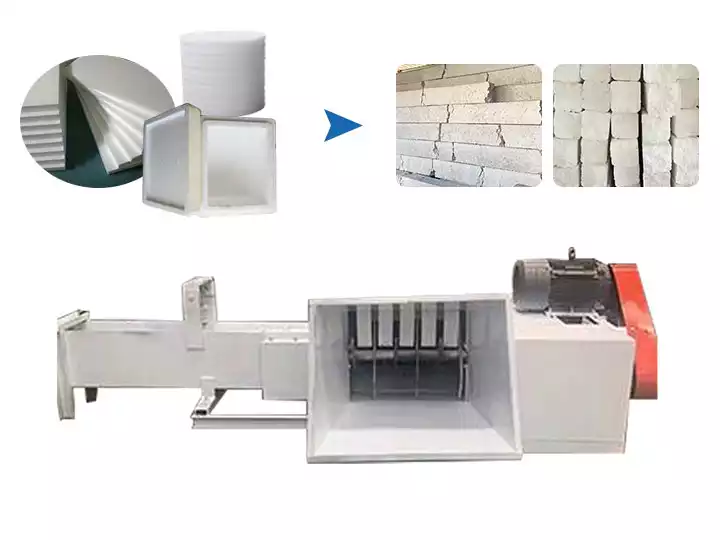

Styrofoam compactor

After the plastic foam is compressed by the EPS styrofoam recycling compactor, the foam density increases, and the foam is in the shape of a square block, which is very convenient for transportation and storage.

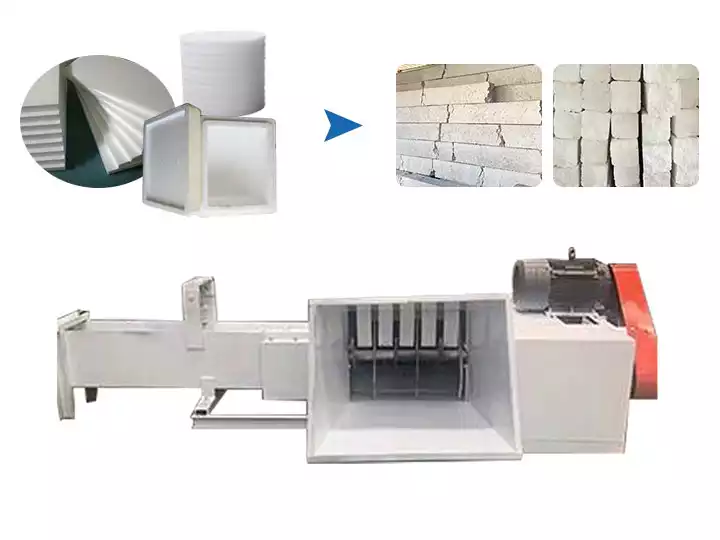

Polystyrene shredder

The polystyrene shredder machne is mainly used to crush various foam materials into small pieces, and the horizontal style is more labor-saving.

EPE EPS granulator

The pelletizer is suitable for extruding and pelletizing EPE and EPS waste plastics as raw materials and processing them into EPE plastic pellets which are in shortage in the plastics industry.

Why need an EPS styrofoam recycling compactor?

EPS foam compaction machine is one of the plastic foam recycling equipment. Due to the large size and light weight of foam, transportation is a big inconvenience. EPS foam cold press can easily compact foam and reduce the volume of plastic.

- The styrofoam compactor is equipped with a separate pre-crushing device, which can crush large pieces of foam directly.

- The foam recycling machine has a high compression ratio, which can reduce the volume of plastic foam by 40 times, saving storage space and convenient transportation, thereby saving storage costs.

- There is no need to add chemical materials and heat during operation, and the processed foam blocks are non-toxic, odorless, and environmentally friendly.

Granulating equipment of plastic foam pelletizing line

EPS foam pelletizing machine

The EPS foam granulator adopts a conical twin-screw barrel, which speeds up the feeding speed and greatly increases the output. The output of the commonly used model is 150-375kg/hour. The plastic granulator machine is produced by the main and auxiliary machines, the heating temperature is stable, the molecular structure of the material is effectively improved, and the quality of the plastic particles is high. The pelletizing unit is mainly composed of crusher, extruder, and automatic traction pelletizer, and the production process is pollution-free.

EPE foam pelletizing machine

The EPE foam granulator includes a feeding system, compaction and extrusion systems. Due to the particularity of EPE plastic, the length of the barrel of the pellet machine is longer than that of the EPS pellet machine, and it is easy to identify by looking at the appearance. All electrical standards of the equipment conform to European standards, and the output is high.

Video of plastic foam pelletizing line

Plastic foam pelletizing line factory display