PP PE Film Torba Plastik Granülleme Hattı için Plastik Geri Dönüşüm Makinesi

| Peletleme Kapasitesi | 100-500 kg/saat |

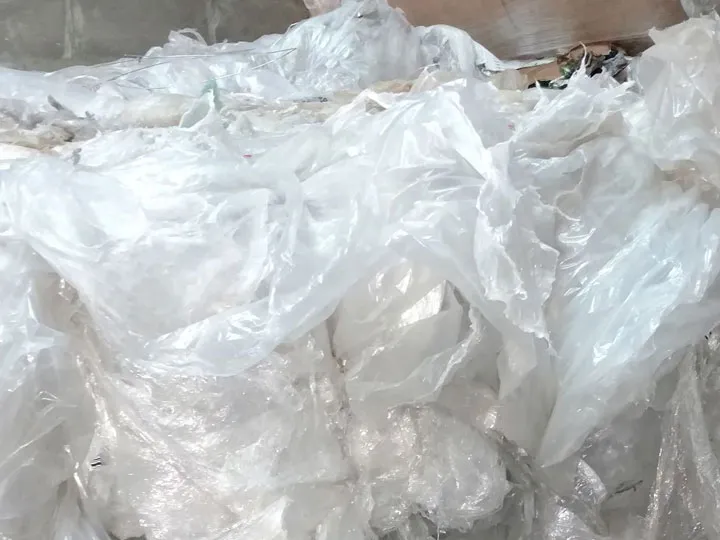

| Uygulama Malzemeleri | Dokuma torbalar, Yumuşak sulama borusu, Gıda ambalajı, Atık çöp torbaları, Tarım filmleri, Plastik yeniden öğütmeler, kesilen torba filmi vb. |

| Çekirdek Ekipman | Plastik Kırıcı, Plastik Granülatör, Yıkama Sistemi |

| Düzenli Çıkış için Saha Alanı Gereksinimleri | 300-500 Metrekare |

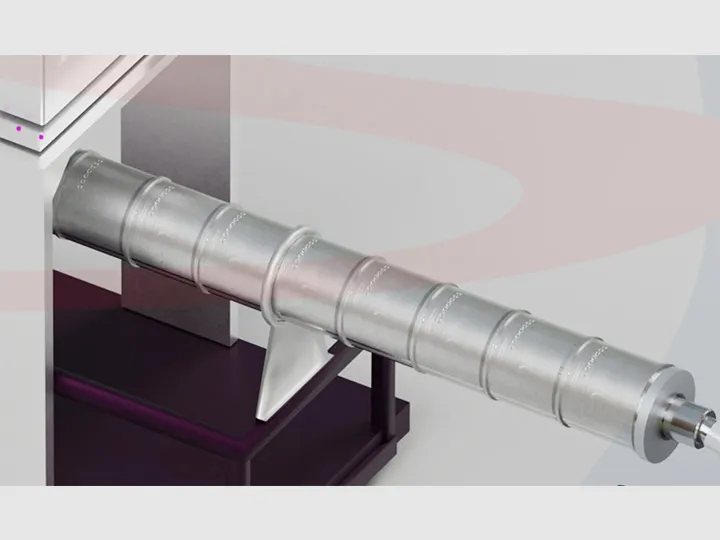

| Mevcut Farklı Ekstruder Vida Modeli | 150 mm, 180 mm, 200 mm vb. |

| Konveyör Adeti | 3-4 |

| Garanti | 12 ay |

| Teslimat süresi | 20-25 gün |

Artık proje yöneticilerimizden teknik detayları isteyebilirsiniz.

Plastik geri dönüşüm makinelerimiz, plastik ambalaj poşetleri, gıda ambalajları, PP rafya poşetleri, dokuma çuvallar, tarım filmleri vb. dahil olmak üzere baskılı ve baskısız PE polietilen (HDPE, LDPE, LLDPE) ve PP polipropilen malzemeyi işlemek üzere tasarlanmıştır. line t, çöp torbası, tarımsal film, gıda ambalajı, şrink ve streç film üreticilerinin yanı sıra dokuma endüstrisindeki PP dokuma çuval, leno torba, jumbo torba ve yumuşak sulama boruları üreticileri için şiddetle tavsiye edilir.

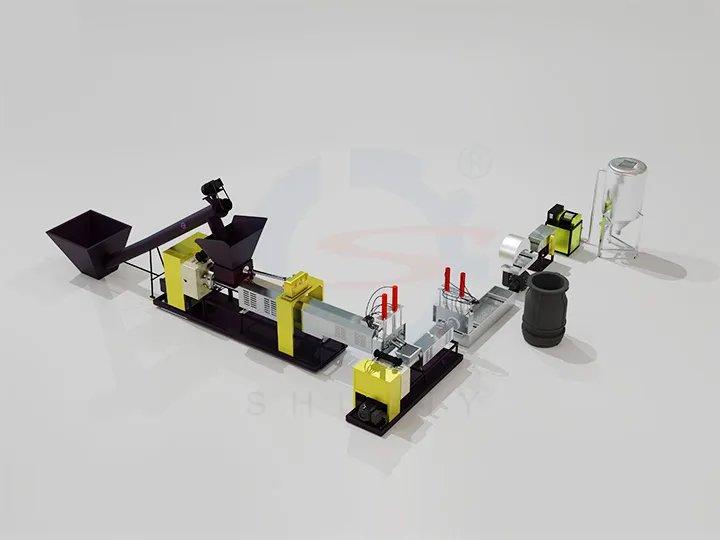

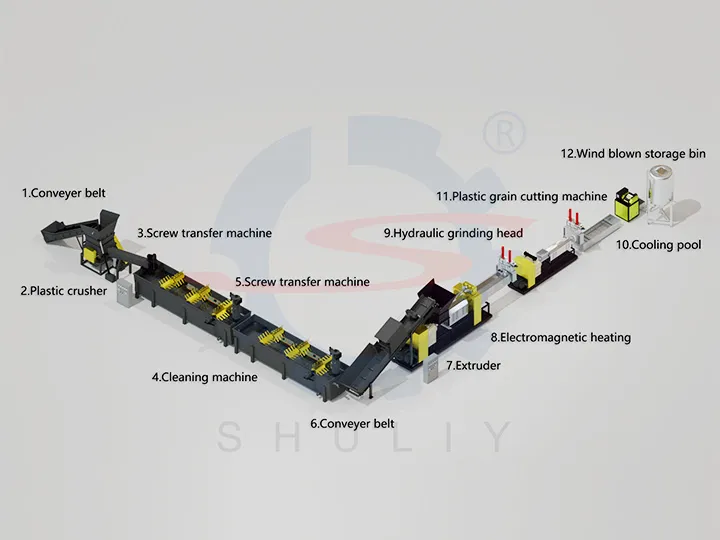

Plastik Peletleme Hattının Tanıtımı

Plastik atıkların ana malzemeleri PP, PE, LDPE, LLDPE, HDPE, PS, PVC vb.'dir. Peletleme hattının tamamı atık plastiklerin kırılmasını, temizlenmesini ve granülasyonunu içerir. Ana plastik poşet geri dönüşüm makinasında plastik kırma ve yıkama makinası, durulama tankı, kurutucular, plastik granülatörler, soğutma tankları ve pelet kesme makinaları bulunmaktadır. Plastik film geri dönüşüm makinası, müşterilerin hammaddelerine ve ihtiyaçlarına göre esnek bir şekilde yapılandırılabilir.

Plastik Film Geri Dönüşüm Makinası Videosu

Videoda fabrikamızda bulunan plastik film geri dönüşüm makineleri gösterilmektedir; satış müdürümüz Sunny size bunların görünüşünü, çalışma prensibini ve makine çıkışını tanıtacaktır.

Peletleme Sisteminin Dört Avantajı

Plastik peletleme sistemimizin dört önemli avantajı: iyi vida tasarımı, doğru besleme sistemi, verimli sıcaklık kontrol sistemi ve sertifikalı redüktör.

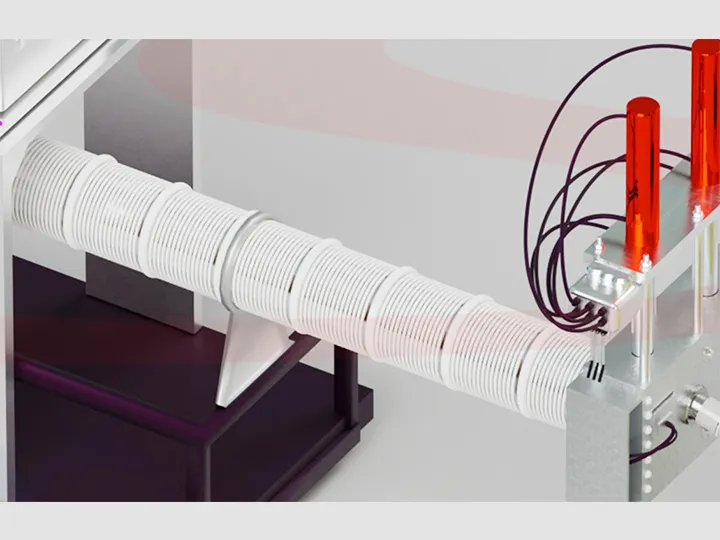

Vida Tasarımı

Vidanın tasarımı, plastiğin sıcak eritme ve ekstrüzyon prosesindeki performansını doğrudan belirleyecek ve bu da sonuçta plastik granüllerin kalitesini etkileyecektir.

Hassas Otomatik Besleyici

Shuliy'nin otomatik besleme hunisi, film malzemesinin dolaşmasını önleyerek beslemeyi kolaylaştırır. Shuliy, taşıma bandı tarafından beslenen malzeme miktarını izlemek, peletleme makinesinin sabit beslemesini ve çalışma hızını hassas bir şekilde kontrol etmek için kameralarla donatılmış depolama siloları tasarladı.

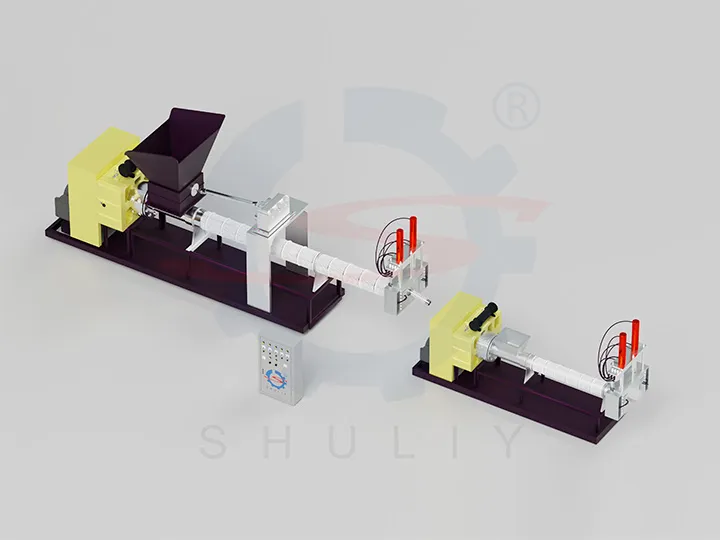

İki Alternatif Isıtma Verimliliği Yöntemi

Shuliy plastik film peletleme hattı, atık plastikleriniz için iki farklı ısıtma yöntemi sağlar: seramik ısıtma ve elektromanyetik halka ısıtma. Her ikisinin de geleneksel demir ısıtma yöntemlerine göre birçok avantajı vardır.

- Elektromanyetik Isıtma Halkaları

Elektromanyetik ısıtmanın termal verimliliği son derece yüksektir ve genellikle 90%'nin üzerine çıkar. Elektrik enerjisinin çoğu doğrudan ısıya dönüştürülerek plastiğin erimesi hızlandırılır ve işletme maliyetleri azalır.

Elektromanyetik ısıtma sistemleri, ısıtma sıcaklığını doğru bir şekilde kontrol edebilir ve farklı erime noktalarına sahip çok çeşitli plastikleri işleyebilir, böylece plastik peletlerin kalitesinin artırılmasına yardımcı olur.

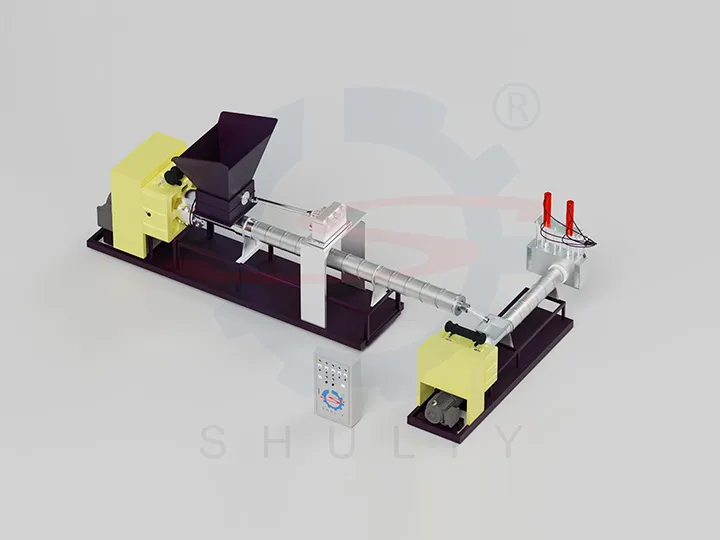

- Seramik Isıtma

Seramik ısıtma sabit bir sıcaklık sağlar, ısıtma yüzeyinin sıcaklığı aynıdır ve aşırı ısınmayı önler, bu da onu enerji açısından verimli, güvenli ve uzun ömürlü kılar.

Sertifikalı Redüktör

Tüm Shuliy peletleme makineleri, yüksek tahrik verimliliği, düşük gürültü seviyeleri, uzun hizmet ömrü ve istikrarlı üretim için sertifikalı sertleştirilmiş dişli redüktörleriyle donatılmıştır.

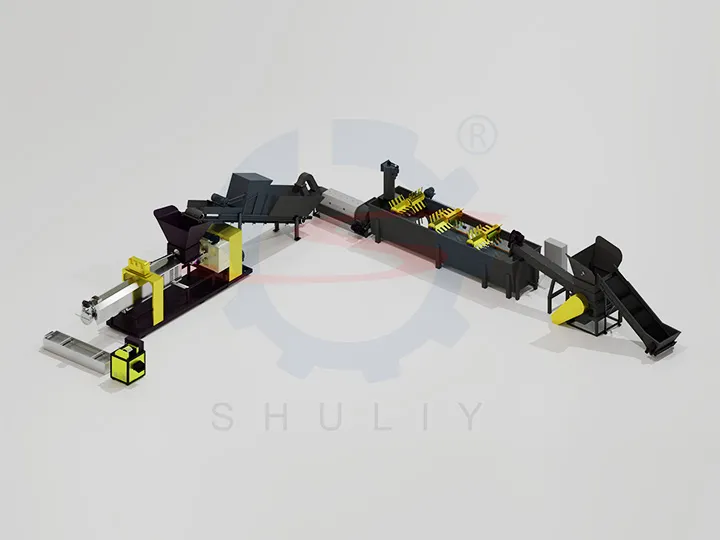

Plastik Peletleme Sisteminin Komple Konfigürasyonu

Plastik Kırma Makinası

Döner tip cihazların ve konveyörlerin dolaşmasını ve tıkanmasını önlemek için uzun plastik filmlerin parçalama makinesi ile küçük parçalar halinde parçalanması gerekmektedir. Parçalayıcı, plastik film parçalama ve temizleme için öncelikli olarak uygundur.

Plastiğin ezilmesinden sonra plastik parçaların yüksek verimlilikle doğrudan temizlenmesiyle karakterize edilir. Kırıcının içinde dönen bir kesici bulunur ve kesici, yumuşak malzemeyi kısa sürede küçük parçalara ayırmak için özel olarak işlenir. Bıçaklar dayanıklılık için yeniden bilenebilir.

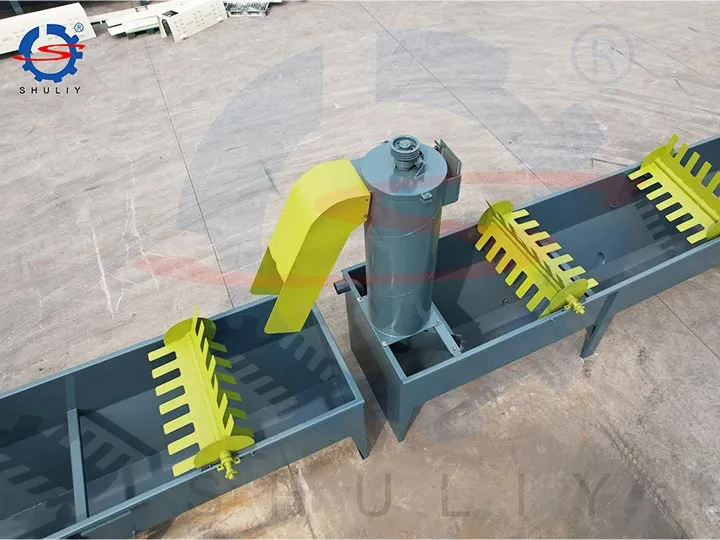

Yıkama Sistemi (Sürtünmeli Temizleme ve Durulama)

Yıkama sistemi esas olarak nihai granüllerin yüksek kalitesini sağlamak amacıyla plastik atıklardaki kiri çıkarmak için kullanılır. Sürtünmeli yıkayıcı sayesinde plastik filmler yüksek hızda birbirine sürtünerek yağ ve kir gibi kirliliklerden kurtulur.

Plastik durulama tankı paslanmaz çelik veya demir plakalardan yapılmıştır. Makinenin üst kısmında plastik parçaları ileri doğru iten çok sayıda dişli karıştırıcı bulunmaktadır. Genellikle yıkama tankının uzunluğu 10 metredir, daha büyük geri dönüşüm kapasitesiyle 20 m veya 30 m'ye kadar özelleştirilebilir.

Plastik Kurutma ve Kaldırma Ünitesi

Durulama tankı ile yıkandıktan sonra, bir dikey susuzlaştırma makinesi film peletleme hattında bağımsız bir rol oynar. Islak plastik filmleri güçlü santrifüj kuvvetiyle kurutabilir, ardından bir sonraki peletleme işlemine (tekrarlanan durulama veya peletleme) kaldırabilir.

Dikey susuzlaştırma makinesinin içinde, spiral taşıma işlemi sırasında malzemeden nemi dışarı atmak için merkezkaç kuvveti kullanan bir spiral besleme cihazı bulunur.

Plastik Eritme ve Ekstrüzyon Prosesi

Bir plastik granülatörü, plastik peletleme hattındaki en önemli plastik geri dönüşüm makinesidir. Plastikleri yüksek sıcaklıkta eriterek ve ardından uzun şeritler halinde ekstrüze ederek granülasyonu gerçekleştirecektir.

Genel olarak plastik iki kademeli peletleme makinesi ile eritilip ekstrüde edilecektir. Bununla birlikte, kapasitesi 1 ton/saatin üzerinde olan peletleme hattı için üç kademeli peletleme ekstrüzyon makinesi de mevcuttur.

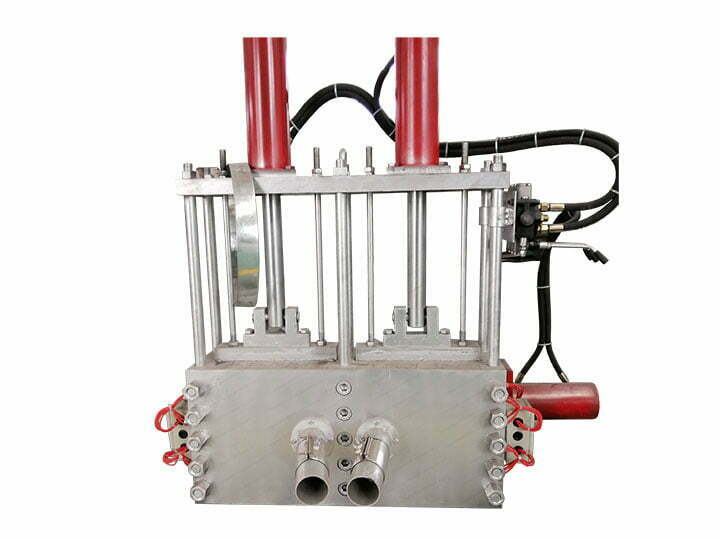

Peletleme Kalıp Kafası

Peletleme kalıpları, plastik eriyiğin ekstrüzyona tabi tutulması için şerit peletleme sistemlerinde kullanılır.

Shuliy, 3 farklı tipte peletleme kafası sunmaktadır (kesintisiz elek değiştiriciler ve motorlu dişli kafaları dahil). Plastik ekstrüzyon koşulları açısından geri dönüşüm tesislerinin farklı gereksinimlerini karşılayabilirler.

Soğutma Cihazı

Soğutma tankı paslanmayan veya korozyona uğramayan paslanmaz çelikten yapılmıştır. Esas olarak plastik granülatörden ekstrüde edilen yumuşak şerit malzemesini sertleştirmek için soğutmak için kullanılır.

Pelet Kesme Cihazı

Bir plastik pelet kesme makinesi, plastik şeritleri plastik peletlere keser ve peletlerin boyutu ayarlanabilir, bu da plastik granülleme hattı için vazgeçilmez bir makinedir. Shuliy bir ip peletleme sistemi ve su halkası peletleme sağlar.

Pelet Depolama için Silo Ünitesi

Plastik granüller boru vasıtasıyla siloya üflenecektir.

Bu depolama, toz birikimini ve doğal israfı azaltır ve pelet kalitesini ve görünümünü daha iyi korur.

Plastik Geri Dönüşüm Makinalarının Özellikleri

- Plastik geri dönüşüm makinesi geniş bir uygulama alanına sahiptir ve PP/PE atık plastik film, PP/PE plastik çöp karışımı, atık PP çimento torbaları, uzay torbaları, evsel çöp plastikleri, atık tarımsal sera filmi, endüstriyel ambalajların geri dönüştürülmesi ve işlenmesi için uygundur. film, alışveriş çantaları vb.

- Plastik geri dönüşüm makineleri esas olarak kırıcı, temizleme havuzu, kurutma makinesi, plastik peletleme makinesi ve diğer ekipmanlardan oluşur. Ekipmanın tamamı son derece otomatiktir ve tüm süreci yürütmek için yalnızca bir çalışana ihtiyaç duyulur, bu da işçilik maliyetlerinden tasarruf sağlar.

- Plastik peletleme hattı düşük enerji tüketimine ve yüksek üretim verimliliğine sahiptir ve üretilen geri dönüştürülmüş plastik peletler, pazar standardına ulaşabilen pürüzsüz yüzeylere ve tekdüze boyuta sahiptir.

Plastik Poşet Geri Dönüşüm Makinası Uygulamaları

Yeniden Kullanılabilir Plastik Peletler Elde Edin

Geri dönüştürülmüş plastik peletler, kullanılan farklı hammaddelere ve işlenmiş plastik peletlerin özelliklerine göre temel olarak sınıflara ayrılır ve bunlar genellikle birinci, ikinci ve üçüncü sınıf malzemelere ayrılır.

- Birinci sınıf malzemenin yüksek kalitesi, kalite için kullanılan hammaddelerin de daha iyi olması veya plastik kullanılmaması anlamına gelir; bunlar, HDPE / LDPE torba kesikleri, kusurlu LDPE fermuarlı torba üretim atıkları gibi sanayi sonrası atıklarda yaygındır. , kenar trimi vb. İşlenen bu plastik peletlerin kalitesi iyidir ve doğrudan plastik ürün üretimine gönderilebilir.

- İkincil ve üçüncü sınıf peletler her zaman tüketici sonrası atıklardandır. Geri dönüşüm malzemeleri kullanıldı. Shuliy Machinery ayrıca yıkanmış, tüketici sonrası atıklarla çalışacak şekilde tasarlanmıştır. Geri dönüştürülen peletler ekstrüzyon işleminde tekrar kullanılabilir. 100% geri dönüştürülmüş peletlerini plastik üretiminde (çöp torbası, sulama borusu üretimi vb.) veya karışımın bir parçası olarak kullanarak üretimde hammadde maliyetlerini azaltabilirsiniz. Geri dönüştürülmüş peletlerin kalitesi, doğrudan masterbatch ve katkı maddeleri eklenerek de geliştirilebilir.

Peletleme için Plastik Geri Dönüşüm Makinesinin 3D Videosu

Plastik Pelet Nasıl Yapılır?

Plastik Poşet Geri Dönüşüm Makinalarının Parametresi

| HAYIR. | Öğe | Teknik veri |

| 1 | Konveyör | Güç:3kw Boyut: Uzunluk 5m Genişlik 0,8m Kapasite: 1000-1200kg/saat |

| 2 | PP PE kırıcı | Modeli:1000 Güç:37kw+11kw Kapasite: 1000kg/saat |

| 3 | Kemer tokası | Güç: 1.5kw Boyut : (U) 4 m* (G) 0,6 mm Kapasite:800-1200kg/saat |

| 4 | Otomatik Besleyici | Güç:3kw Kapasite:800-1200kg/saat |

| 5 | Ana Plastik Granülatör | Modeli: SL-220 Vida çapı: 220mm Vida uzunluğu: L1,6m Motorlu:22+18,5kw |

| 6 | Yardımcısı Plastik Kırma | Modeli: SL-260 Vida çapı: 260 mm Vida uzunluğu: 3,6m Motor: 110kw |

| 7 | Pelet Kesme Makinası | Güç: 1.5kw Boyut: 1000*1200*1100mm |

| 8 | Plastik Pelet Torbalama Makinesi | Modeli:1000 Güç:37kw+11kw Kapasite: 1000kg/saat |

Tesisimizde Plastik Granülatör ve Plastiğin Geri Dönüşümünü Sağlayan Diğer Makine

Plastiği Geri Dönüştürecek Makine Almanya'ya Sevk Edildi

Almanya, yaklaşık geri dönüşüm oranıyla atık ayırma ve geri dönüşüm açısından dünyanın en iyi ülkelerinden biridir. Ayrıca, Alman müşterilerle başarılı vakalarımız bulunmaktadır. Ulusal politikanın teşvikiyle Alman müşterimiz geçen yıl, ağırlıklı olarak bazı atık plastik alışveriş poşetlerini geri dönüştürerek bir plastik geri dönüşüm işi başlatmaya karar verdi. Makine satın almak için çevrimiçi olarak üreticiler aradı ve bizi buldu.

Fabrikamız on yılı aşkın bir süredir plastik torba geri dönüşüm makineleri üretip satmaktadır ve zengin deneyime sahiptir. Satış yöneticisi müşterinin ihtiyaçlarını anladıktan sonra birkaç farklı teklifte bulunur. Müşterinin sorunuyla karşı karşıya kaldığımızda onu etkili bir şekilde çözeriz. Sonunda müşterinin güvenini kazandı ve plastik granülasyon hattı Almanya'ya sevk edildi.

Dünya Çapındaki Küresel Plastik Peletleme Hatları Vakaları

Shuliy plastik geri dönüşüm makineleri 20'den fazla ülkeye ihraç edilmektedir. Her türlü plastik atıkların geri dönüşümünde kullanılırlar. Müşterilerimiz Shuliy plastik geri dönüşüm makineleri ve hizmetleri hakkında çok iyi geri bildirimlere sahipler. Lütfen aşağıdaki başarılı vakalara bakın.