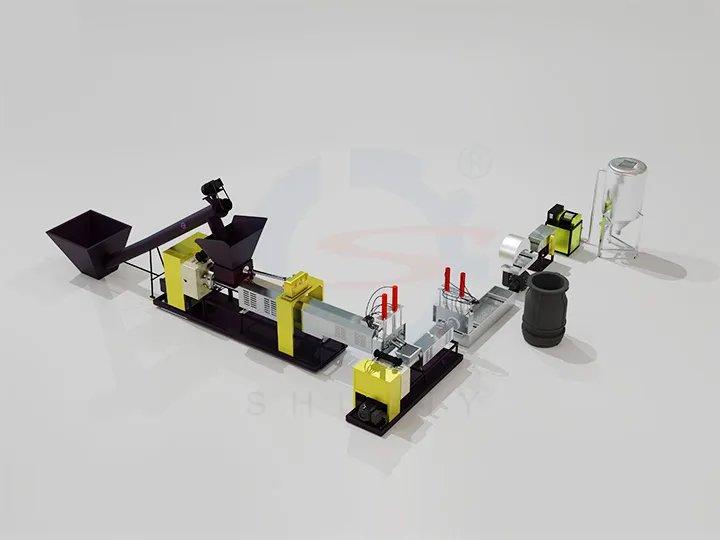

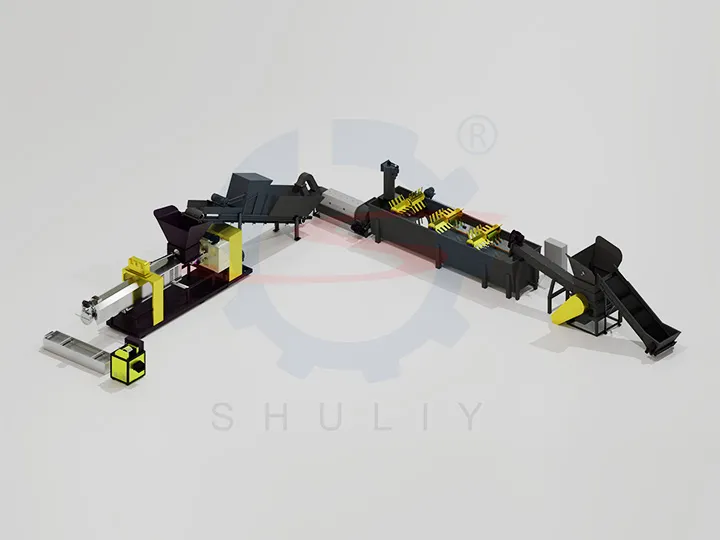

PP PE Plastik Film Dokuma Çanta Peletleme Makinesi

| Makine modeli | SL-125, SL-150, SL-180, SL-200, SL-220 |

| Kapasite Aralığı | 180-420kg/saat |

| Geri Dönüşüm Malzemesi | Dokuma çuvallar, dokumasız torbalar, Çimento torbaları, Rafya torbalar, halatlar, Plastik topaklar, Torba hurdaları |

| Malzeme Türü | PP, PE, LDPE, LLDPE vb. |

| Çekirdek bileşen | Kuvvet besleyici, Redüktör, Vida, Isıtma halkaları, peletleme kalıp kafası |

| Garanti | 1 yıl |

Artık proje yöneticilerimizden teknik detayları isteyebilirsiniz.

PP PE plastik film peletleme makinesi, kırma, sıkıştırma, eritme ve ekstrüzyon işlevlerini tek bir adımda birleştirir. Shuliy Group, 20 yılı aşkın bir süredir plastik film peletleme makineleri üretiyor ve birçok geri dönüşüm tesisinin kendi işini kurmasına ve büyük kar elde etmesine yardımcı oluyor.

Peletleme makinesi, atık plastik filmlerin peletlenmesine ek olarak PP PE dokuma torbaları, çimento torbalarını, PP rafyaları, plastik ambalaj torbalarını vb. de peletleyebilir. Plastik peletleme makinesinin son ürünleri, doğrudan boru ekstrüzyonu, plastik üretimi, film üfleme ve plastik enjeksiyonda kullanılabilen geri dönüştürülmüş peletler veya granüllerdir.

Peletleme makinesi çalışma prensibi

Ekstrüzyon sistemi: plastik film pelletizing makinesinin ekstrüzyon sistemi vida, silindir, hazne, başlık ve delikten oluşur; plastik, ekstrüzyon sistemi üzerinden tekdüze bir eritme halinde sınıflandırılır ve süreçte oluşturulan basınç altında vida tarafından başlıktan sürekli olarak dışarı ekstrüde edilir.

- Vida: Film peletleme makinesinin prensibi en önemli parçaları oluşturur, doğrudan ekstruderin uygulama alanı ve üretim verimliliği ile ilgilidir, yüksek mukavemetli korozyona dayanıklı alaşımlı çelikten yapılmıştır.

- Namlu: dikişsiz bir metal boru, genellikle ısıya dayanıklı, basınca dayanıklı, yüksek mukavemetli, güçlü aşınmaya dayanıklı, korozyona dayanıklı alaşımlı çelik veya kompozit çelik boru ile kaplanmış alaşımlı çelik.

- Hazne: Haznenin alt kısmı, malzeme akışını ayarlamak ve kesmek için bir kesme cihazı ile donatılmıştır; haznenin yan tarafında bir görüş deliği ve kalibrasyon ölçüm cihazı bulunur.

- Kafa ve kalıp: Kafa, alaşımlı çelik iç manşon ve karbon çeliği dış manşondan oluşur, kafa bir kalıplama kalıbı ile donatılmıştır.

Teknoloji sistemi: Dokuma poşet pelletizer makinesinin prensibinde, iletim sisteminin rolü vidasını çevirmek, ekstrüzyon işlemi sırasında gerekli tork ve hızı vida için sağlamak, genellikle motor, redüktör ve yataklar ile diğer bileşenler tarafından gerçekleştirilir.

Isıtma ve soğutma cihazları: Günümüzde dokuma poşet pelletizer makinesi genellikle elektrikli ısıtma kullanır; bu ısıtma direnci ve indüksiyon ısıtması olarak ikiye ayrılır ve ısıtma elemanı gövdenin her kısmına, boynuna ve başlığa kuruludur. Dışardan içeriye doğru ısıtma cihazı, mantarın içindeki plastik malzemeyi işlem operasyonu için gereken sıcaklığa ısınacak şekilde ısıtır. Soğutma cihazı, plastik malzemenin pellet üretim sürecinde gerekli sıcaklık aralığında kalmasını sağlamak için kurulur.

Peletleme makinesinin çalışma videosu

Teknik özellikler

| Modeli | SL-125 | SL-150 | SL-180 | SL-200 | SL-220 |

| Vida çapı | 125mm | 150mm | 180mm | 200 mm | 220 mm |

| Mil hızı | 50-70/dak | 40-50/dak | 40-50/dak | 40-50/dak | 40-50/dak |

| Ana motor gücü | 30kw | 37 kW | 55kw | 75kw | 90 kW |

| Ağırlık | 1.8T | 2T | 2.2T | 2.8T | 3.2T |

| Demanslar | 2.6*0.7*0.7 | 3.0*0.7*0.8 | 3.2*0.7*0.8 | 3.5*1*1 | 3.8*1.2*1 |

| Kapasite | 180kg/saat | 300kg/saat | 350kg/saat | 380kg/saat | 420kg/saat |

- CE sertifikası mevcuttur.

- Shuliy Group, talebiniz doğrultusunda daha büyük güç ve çıktı ile daha fazla plastik pelet makineleri modeli sunar.

Dokuma torba granülatörünün ek görüntüleri

Plastik film peletleme makinesi için sorular

Sağ köşedeki formu doldurarak sorularınızı bize iletin, proje yöneticimiz en kısa sürede sizinle iletişime geçerek malzemelerinize özel hizmet ve geri dönüşüm çözümleri sunacaktır.