PP LDPE HDPE Geri Dönüşümü için Plastik Granül Yapma Makinesi

| Vida çapı | 105, 125, 135, 150, 180mm |

| Malzemeyi geri dönüştürün | Arızalı üflemeli kalıplanmış filmler/torba, enjeksiyonla kalıplanmış malzeme, plastik yeniden öğütme, ısıyla şekillendirilmiş ambalaj, otomotiv parçası, tarım filmi, çöp torbası |

| Başvuru | Şişirme üreticisi, enjeksiyon kalıplama üreticisi, plastik geri dönüşüm merkezi |

| Malzeme Türü | PP, AYPE. LLDPE, HDPE, PVC, PC, PA, ABS |

| Peletleyici markası | Shuliy Makina |

| Ekstrüzyon Çıkışı | 100-500KG/saat |

Artık proje yöneticilerimizden teknik detayları isteyebilirsiniz.

platik granül yapma makinesi, ayrıca plastik pelletleme makinesi olarak da bilinir, plastik atıkları yüksek karla geri dönüştürülmüş plastik pelletlerine eritmek ve ekstrüde etmek için kullanılır. İkili aşamalı pelletleme sistemi, plastik geri dönüşüm tesisleri için yaygın bir modeldir, kapasitesi saatte 100-500 kg, günde 2200-11000 kg'a ulaşabilir.

Bu arada Shuliy Machinery'de tek ve üç kademeli peletleme makineleri de mevcuttur; özel ekstrüzyon modeline geri dönüşüm malzemeleriniz, istenen çıktı, fabrika alanı, bütçe vb. göre karar verilir.

Plastik Granül Yapma Makinesinin Özellikleri

Peletleme Sisteminin Çoklu Konfigürasyonları

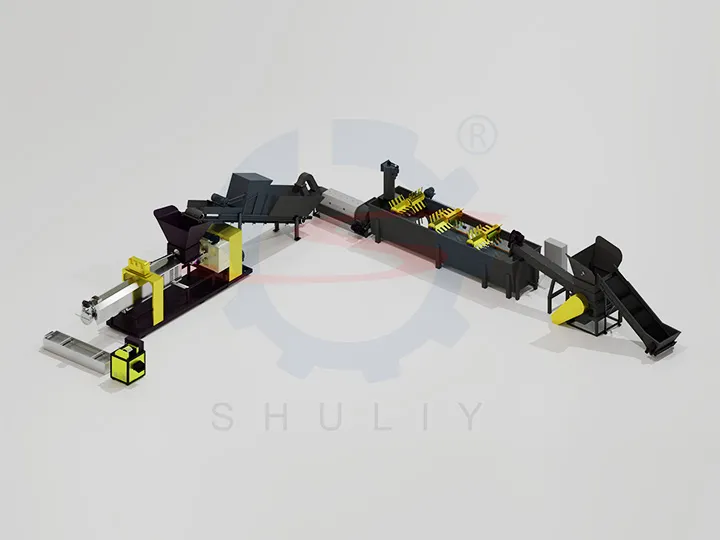

Plastik granül yapım makineleri için üç farklı eşleştirme stili sunuyoruz.

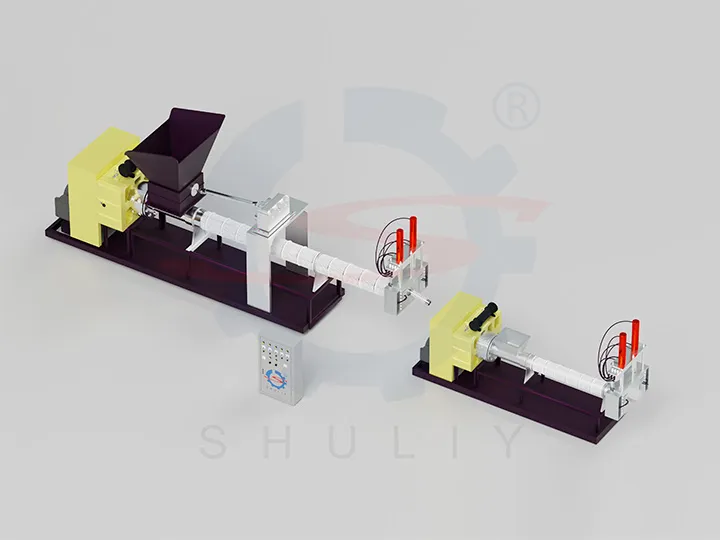

İlk olarak tek kademeli peletleme sistemi. Geri dönüşüme yeni başlayanlar için temel bir seçimdir. Üretimi ve fiyatı geri dönüşüm alanında yeni girişimciler için uygundur.

İkinci olarak, tesisiniz ne kadar büyük veya küçük olursa olsun, çift aşamalı peletleme sistemi çoğu plastik geri dönüşüm tesisi için ideal sistemdir. “Ana peletleme makinesi” diyebileceğimiz ilk aşama, geri dönüşüm malzemelerini ısıtarak plastik eriyiğe dönüştürebiliyor. Ancak bir plastik erime süresi kısa ve kabadır. Özellikle safsızlık içeriği yüksek, erime noktaları yüksek veya çıktısı yüksek olan bazı plastikler için ham maddeyi eşit şekilde eritmek mümkün değildir.

Bu nedenle ilk aşamadan sonra mutlaka “bebek peletleme makinesi” kurulmasını öneriyoruz. İkinci aşama peletleyici, geri dönüşümcünün safsızlığı azaltmasına ve plastik granül kalitesini artırmasına yardımcı olabilir.

Son olarak, üç aşamalı peletleme sistemi de geri dönüşüm endüstrisinde oldukça popülerdir. Kapasitesi 500 kg/saat'in üzerinde olan ekstrüzyon peletleme hattı için tasarlanmıştır veya geri dönüşümcünün nihai plastik granüller için çok yüksek bir standardı vardır. İlgileniyorsanız daha fazlasını öğrenmek için bizimle iletişime geçin.

Alternatif Plastik Eritme Yöntemleri

Plastik peletleme işlemi yüksek sıcaklıklar gerektirdiğinden, plastik peletleme endüstrisindeki enerji tüketiminin maliyetinin de dikkate alınması gerekir.

Günümüzde, piyasadaki plastik granül yapma makinesi, demir ısıtma bobinli ısıtma ve seramik ısıtmalı plastik peletleme makineleri ile desteklenen, esas olarak elektromanyetik ısıtmadan oluşan bir model oluşturmuştur. Elektromanyetik ısıtmanın etkisi diğer ikisine kıyasla en iyisidir. Shuliy Machinery tarafından geliştirilen atık plastik granül yapma makinesi, hızlı ısıtma hızıyla enerji açısından verimli, güvenli ve güvenilir olan yüksek frekanslı elektromanyetik ısıtıcının yeni teknolojisini benimser.

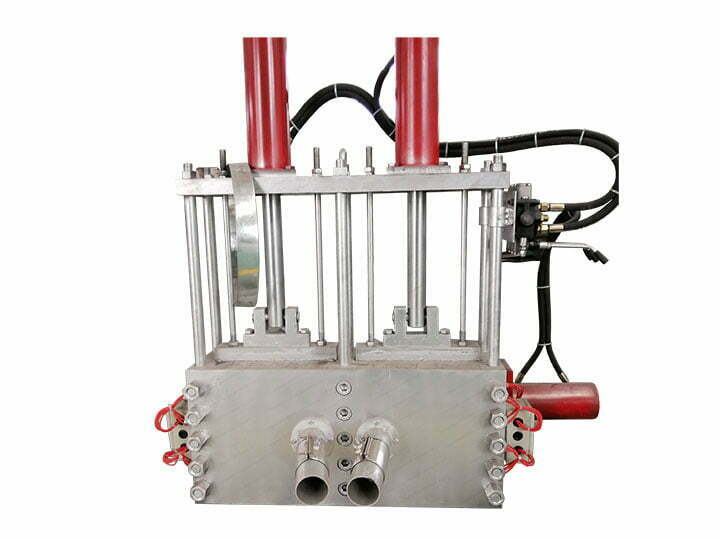

Verimli Peletleme Kalıp Kafaları

Plastik peletleme makinesinin kalıp kafası farklı tiplere sahiptir. Bunlar elektrikli dişli pafta kafaları ve hidrolik pafta kafalarıdır. Elektrikli dişli kalıp kafasının kalıp ekranını manuel olarak değiştirmesi gerekir ve daha düşük bir fiyata sahiptir, bu da deneyimi olmayan yeni başlayanlar için daha uygundur.

Çift pafta kafalı hidrolik model çok daha verimlidir. İç eleklerden biri kirlendiğinde ve değiştirilmesi gerektiğinde, başka bir peletleme kalıbı sürekli olarak çalışmaya başlayacaktır. Zamandan ve insan gücünden tasarruf sağlar, aynı zamanda daha büyük plastik ekstrüzyon kapasitesi ve ekstrüzyon kuvveti ihtiyaçlarını da karşılayabilir.

Müşteriler, geri dönüşüm ekstruder makineleri için ihtiyaçlarına ve bütçelerine göre doğru kalıp kafasını seçebilirler.

Doğru kalıp kafasını seçmekte karışıklık yaşıyorsanız, bize ulaşın şimdi, satış yöneticimiz sizin için doğru olanı önerecek ve size en iyi makine fiyatını sağlayacaktır.

Peletleyici Kesim Tipi

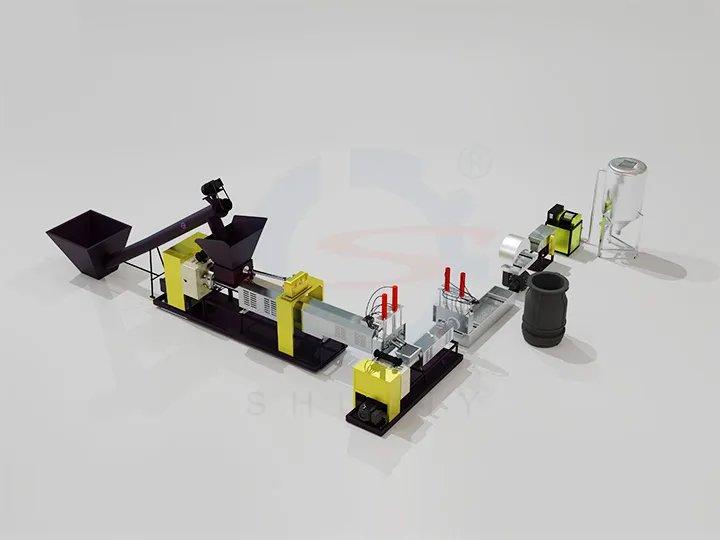

- İplik peletleme sistemi

İplik peletlemede, kalıp kafası plastik eriyiği şeritler halinde sıkar, bunlar bir su soğutma tankında soğutulur ve sertleştirilir ve daha sonra bir plastik granül kesici tarafından kesilir.

- Su halkalı peletleme sistemi

Su halkalı peletleme sistemi farklı olacaktır. Plastik eriyik ekstruder kalıp kafasından ekstrüde edilir ve ardından doğrudan dönen bıçaklar tarafından kesilir.

Plastik granüller hemen suda soğutulur, yıkanır ve titreşimli bir masa üzerinde sudan ayrılır ve ardından santrifüjlü susuzlaştırma ekipmanında kurutulur.

PP Granül Makinasının Çalışma Videosu

Uygun Geri Dönüşüm Malzemeleri Nelerdir?

Granül üretim makinesi, peletleme için PP, HDPE, LDPE, LLDPE, PS, PA, ABS, PVC ve diğer plastik türlerinin üretimine uygun özel bir vida tasarımı ve farklı konfigürasyonları benimser.

Shuliy plastik granül yapma makineleri, enjeksiyon kalıplama yeniden öğütme malzemeleri, ısıyla şekillendirilmiş ürünler, tişört poşeti kesikleri, kenar kaplamaları, kusurlu şişirilmiş film ürünleri, atık endüstriyel film, tarımsal film, ev alışveriş çantaları, borular, dokuma dahil olmak üzere birçok hammaddeyi işleyebilir. çantalar, fıçılar, şişeler, fıçılar, mobilyalar, günlük ihtiyaçlar vb. Granül üretim makinesi plastik kirliliğini azaltmamıza yardımcı olabilir. Atık plastik geri dönüşüm endüstrisindeki en çok yönlü, yaygın olarak kullanılan ve en popüler plastik geri dönüşüm ekstrüzyon makinesidir.

Peletleme Makinesinin Son Granülleri

Nihai ürünler geri dönüştürülmüş granüllerdir, plastik geri dönüşüm endüstrisinde hayati bir rol oynarlar ve kaliteleri, sonraki ürünlerin ve pazar uygulamalarının performansı üzerinde doğrudan etkiye sahiptir.

Shuliy peletleyiciler aşağıdaki kriterleri karşılayan plastik peletler üretir.

- Yüksek saflık: Shuliy'nin granül yapım ekipmanı ve konveyörü, geri dönüşüm sırasında metal, kağıt, yağ ve diğer plastik olmayan malzemeler gibi yabancı maddelerin karıştırılmasını önleyerek saflığı etkili bir şekilde arttırdığından, yüksek kaliteli plastik geri dönüşüm peletleri yüksek derecede saflığa sahiptir. ürünün.

- Yüksek Tekdüzelik: Shuliy granül yapma makinesi, eritme, plastikleştirme ve ekstrüzyon aşamaları sırasında sabit sıcaklıklar sağlayan benzersiz şekilde tasarlanmış üç aşamalı bir vida kullanır. Ekstrüzyona tabi tutulmuş nihai granüllerin kalitesinin ve boyutunun tek biçimli olmasını sağlamak için tam erime ve plastikleştirme.

- Renk ve parlaklık: Shuliy granül makinesi tutarlı renkte ve iyi parlaklığa sahip peletler üretir ve doğru kullanıldığında hava kabarcıklarını ve siyah lekeleri önler.

PP LDPE HDPE Granül Yapma Makinesinin Yapıları

Bu geri dönüşüm için plastik granül yapma makinesi esasen bir besleme portu, vida presi, pres odası, ısıtma cihazı, boşaltma portu, kalıp başlığı, redüktör ve diğer parçalardan oluşmaktadır. Bu plastik pelletleme makinesi, plastik geri dönüşüm hattının ana geri dönüşüm makinesidir ve çeşitli plastik malzemeleri işleyebilir.

Peletlenecek malzemeye bağlı olarak peletleme makinesi içindeki vidanın çapı, vida ile namlu duvarı arasındaki mesafe ve vidanın uzunluğu farklılık gösterir. Bu nedenle bir plastik peletleme makinesi aynı anda birden fazla malzemeyi işleyemez.

Satılık Plastik Peletleme Makinesi Parametreleri

Satılık plastik peletleme makinesinin modeli, adını PP PE peletleme makinesinin vida çapından almaktadır, örneğin model 180'in vida çapı 180 mm'dir. Aşağıdaki türler arasında model 210, büyük üretimi ve uygun fiyatı nedeniyle pazardaki en popüler olanıdır. Eğer ilgileniyorsanız, danışmaya hoş geldiniz.

| Tip | 105 | 125 | 135 | 150 | 180 | 210 | 220 |

| Vida çapı | 105mm | 125mm | 135 mm | 150mm | 180mm | 210 mm | 220 mm |

| Mil hızı | 50-70/dak | 50-70/dak | 40-50/dak | 40-50/dak | 40-50/dak | 40-50/dak | 40-50/dak |

| Ana motor gücü | 18,5 kW | 30kw | 37 kW | 37 kW | 55kw | 75kw | 90 kW |

| Redüktör sert dişli | 200 | 225 | 250 | 250 | 280 | 315 | 330 |

| Ağırlık | 1,3 ton | 1.8T | 2T | 2T | 2.2T | 2.8T | 3.2T |

| Boyut | 2,4*0,7*0,7m | 2,6*0,7*0,7 m | 2,8*0,7*0,7 m | 3.0*0.7*0.8m | 3,2*0,7*0,8m | 3,5*1*1m | 3.8*1.2*1m |

| Çıktı | 150kg/saat | 180kg/saat | 200kg/saat | 300kg/saat | 350kg/saat | 380kg/saat | 420kg/saat |

Plastik Granül Yapma Makinesi Videosu

Plastik Geri Dönüşüm Peletleme Makinesinin Önlemleri

Peletleme makinesini kullanmadan önce bilmeniz gereken bazı önlemler vardır. Bu, makinenin genel performansını daha iyi sağlayabilir ve hizmet ömrünü uzatabilir.

- Operatör, plastik peletleme makinesinin içine metal nesneler veya sert nesneler koymamaya dikkat etmelidir, aksi takdirde makine zarar görür. Besleme portunun çevresine düşebilecek nesneler koymayın.

- Operatör, dozaj işlemi sırasında sıcaklığı kontrol etmelidir. Genel olarak, atık plastik peletleme makinesinin ana vidasının sıcaklığı yaklaşık 200 dereceye ayarlanır ve yardımcı vidanın sıcaklığı genellikle yaklaşık 160 dereceye ayarlanır.

Neden Shuliy Plastik Granül Yapma Makinesini Seçmelisiniz?

- Shuliy Machinery, dış ticarette geniş deneyime sahiptir ve müşterilerimize ihtiyaçlarına uygun tüm granül makinelerinin yanı sıra bileşenler, uluslararası lojistik ve plastik geri dönüşüm çözümleri de sunmaktayız.

- Shuliy, plastik geri dönüşüm makineleri imalatında 10 yıldan fazla deneyime sahiptir ve makinelerimizin kalitesini garanti eder. Üretim tesislerimizin yanı sıra araştırma ve geliştirmeye de büyük yatırımlar yaptık, kalitelerini korurken geri dönüşüm makinelerimizin performansını geliştirdik ve geliştirdik.

- Yıllar süren sıkı çalışmamız sonucunda çok sayıda yüksek vasıflı çalışan yetiştirdik. Talebinizi aldıktan sonra satış ekibimiz sizinle iletişime geçecek ve plastik granül üretim tesisi maliyeti ve plastik granül yapım makinesi fiyatı dahil olmak üzere makine ayrıntılarını size tanıtacaktır.

Küresel Granül Üretimi Durumu

PP Granül Yapma Makinesi

Son zamanlarda, Shuliy Makine, Gana'ya plastik geri dönüşüm makineleri ihraç etti. Müşterimiz makinelerin videolarını izledi ve bir PP granül üretim makinesi satın almaya karar verdi. Satış yöneticimiz Sunny ile iletişime geçtikten sonra bir granülatör ve bir plastik granül kesici satın almaya karar verdiler. Şimdi, Gana’daki müşterimiz makinelerimizi aldı ve plastik granül üretimine başladı.

Dün bize bir çalışma videosu gönderip şükranlarını ilettiler, granülasyon makinesinin tam anlamıyla taleplerini karşılayabilecek kapasitede olduğunu söylediler. Aşağıda paketlenmiş PP granül makinesi ve onlardan bir geri bildirim videosu gösterilmektedir.

Plastik Granül Üretim Makinesinin Diğer Küresel Durumları

PP HDPE LDPE PVC için Shuliy plastik granül üretim makineleri 30'dan fazla ülkede kurulmuştur. Bu ülkeler arasında Gana, Almanya, BAE, Birleşik Krallık, Kenya, Suudi Arabistan, Etiyopya vb. yer almaktadır. Burada referans olması açısından bazı nakliye ve yükleme resimleri verilmiştir. Eğer ilgileniyorsanız, lütfen bizimle iletişime geçmekten çekinmeyin.

Devamını oku:

- Etiyopya'da Plastik Geri Dönüşüm İşi İçin Fırsatlar

- Suudi Arabistanlı Müşteri Hurda Geri Dönüşümü İçin Shuliy HDPE Granül Yapma Makinesini Seçti

- Etiyopya'ya teslim edilen PP granül makinesi için Hızlı Teslimat

- Umman Müşterisi Shuliy HDPE Yeniden Öğütme Granül Yapma Makinesinden Büyülendi

Aşağıdaki video, plastik peletleme makinelerimizi kullanan küresel plastik granül üretim fabrikalarını göstermektedir. Ekipmanı zaten aldılar ve kurulumu tamamladılar. Çalışma videosunu çekip memnuniyetlerini bize ilettiler.

Bir Komple Geri Dönüşüm Peletleme Hattı Seçin

Shuliy Grubu, müşterilerimiz için eksiksiz bir plastik geri dönüşüm hattı sağlar. Plastik geri dönüşüm hattı; bantlı konveyör, plastik kırıcı, plastik yıkama tankı, plastik granül üretim makinesi, soğutma tankı ve granül kesici içerir. Ayrıca müşterilerin taleplerine göre özelleştirilmiş bir granül hattı da sunabiliriz.

İşinize Başlamak için Profesyonel Plastik Peletleyici Üreticilerini Bulun

Shuliy Makine, Çin'deki en profesyonel plastik pelet makineleri üreticilerinden biridir, İster bir plastik geri dönüşüm tesisi sahibi olun ister yeni bir işletme başlatıyor olun, size en iyi çözümü ve en iyi granül yapma makinesi fiyatını sunabiliriz.

- Hangi malzemeleri toplayıp geri dönüştüreceğinizi bize bildirin.

- İdeal son ürününüzün neye benzediğini bize anlatın.

- Plastik geri dönüşüm tesisinizin kapasitesine karar verin.

- Bütçenizi ve istediğiniz granülatör fiyatını bize bildirin.

- Web sitesi formu aracılığıyla Shuliy Group ile iletişime geçin; proje yöneticimiz uygun plastik granül üretim makinesini önerecek ve sizin için geri dönüşüm çözümlerini özelleştirecektir.