横型廃タイヤ圧縮機

| モデル | SLB-200T(ヘビーデューティ)、SLS-200T(標準) |

| システム圧力 | 2000KN(200トン) |

| ベールの重さ | 1500kg、700-800kg(廃タイヤ) |

| 毎時出力 | 5バレル/時間、4バレル/時間 |

| 給料 | コンベア |

技術的な詳細についてプロジェクト マネージャーに問い合わせることができるようになりました

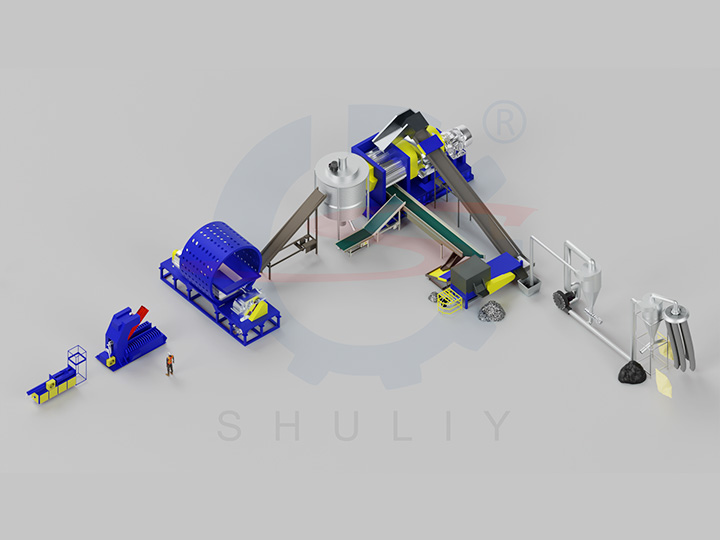

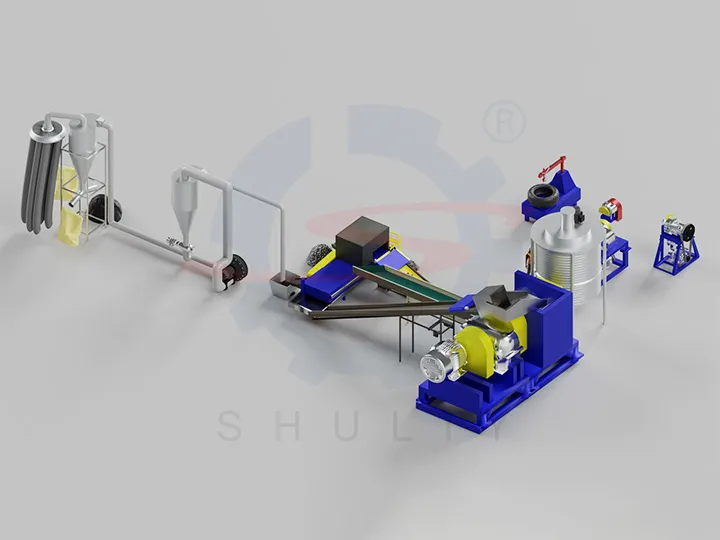

廃タイヤの膨大な量を管理することは、リサイクルセンターや熱分解プラントにとって主要な物流上の課題です。廃タイヤの緩い体積は、輸送コストの高騰と非効率な保管を引き起こします。Shuliyの200シリーズ横型廃タイヤバレルは、この問題を圧倒的な油圧力で解決し、ゴム素材の高い反発弾性を克服するように設計されています。

一般的な段ボールやプラスチックバレルとは異なり、この機械はQ345/355構造鋼で強化されており、圧縮されたタイヤが外向きにかかる特定の圧力に耐えられるようになっています。

高圧圧縮アーキテクチャ

この装置のコアコンピタンスは、「クローズドエンド」(ドアタイプ)設計と2000KN(200トン)の油圧システムにあります。タイヤのように記憶と反発性が高い材料には、オープンエンドの連続バレルは最大密度を達成できないことがあります。

当社の横型廃タイヤバレルは、ヘビーデューティな油圧ゲートを採用しています。圧縮サイクル中、ドアはロックされたままで、マスターシリンダ(Φ351mm径)が固体壁に全圧力をかけます。これにより、ゴムの空隙が最小限に抑えられます。

- システム圧力:高低圧の組み合わせで2000KNに達します。

- 油圧安定性:ダブルベーンポンプシステムと水冷によって24時間の運転サイクル中に油の粘度を維持します。

タイヤバレルモデル分析:SLB-200T対SLS-200T

この200トンシリーズには、異なる施設のスループットと物流要件に合わせた2つの異なる構成を提供しています。

フラッグシップ:SLB-200T(高密度出力)

最大積載効率を必要とする大規模運用向けに設計されています。

- バレル重量:1500kgの巨大なバレルを生産します。

- 電力:45kWのメインモータを搭載し、大きな油圧容量を駆動します。

- バレル寸法:W1250 * H1250 * L1700mm

- 効率:1時間あたり5バレル(約7.5トン/時間)を処理可能。このモデルは、40HQコンテナの積載に最適で、ペイロードを約26-28トンに最大化します。

標準:SLS-200T(経済的ソリューション)

地元のタイヤリサイクル工場ラインに供給する中規模施設に適しています。

- バレル重量:管理しやすい700-800kgのバレルを生産します。

- 電力:37kWのメインモータを利用します。

- バレル寸法:W1130 * H850 * L1700mm

- 効率:1時間あたり4バレル(約3トン/時間)を処理。40HQコンテナの積載に最適で、ペイロードを約26-28トンに最大化します。

運用ワークフローと自動化

油圧タイヤバレル機をラインに組み込むには、材料の流れを理解する必要があります。Shuliyシステムには、標準装備として専用の給料コンベヤ(長さ9.5メートル)が含まれており、手動給料の安全リスクを排除します。

- 給料:滑り止めベルト付きの5.5kWコンベヤがタイヤをチャンバーに運びます。

- 圧縮:PLCインテリジェント制御キャビネットが自動的に圧縮サイクルを管理します。

- 手動結束:バレル長さ(調整可能)に達したら、オペレーターがワイヤーを手動で通します。SLB-200Tは6-8本のワイヤーを必要とし、SLS-200Tは4本のワイヤーでバレルを固定します。

- 排出:バレルが排出され、フォークリフトでの取り扱いが可能です。

技術仕様比較

以下は、施設に適したタイヤリサイクルバレルを選択するための詳細なデータ比較です。

| パラメータ | SLB-200T(ヘビーデューティ) | SLS-200T(標準) |

|---|---|---|

| システム圧力 | 2000KN(200トン) | 2000KN(200トン) |

| メインモータの電力 | 45 kW | 37 kW |

| バレルサイズ(WHL) | 1250 * 1250 * 1700 mm | 1130 * 850 * 1700 mm |

| ベールの重さ | 1500kg(廃タイヤ) | 700-800kg(廃タイヤ) |

| 毎時出力 | ~5バレル/時間 | ~4バレル/時間 |

| 機械重量 | 22トン | 17.5トン |

| 冷却システム | 水冷却 | 水冷却 |

| 給料 | コンベヤ(9500*1900mm) | コンベヤ(9500*1750mm) |

横型廃タイヤバレルの設置とサービス

この横型廃タイヤバレルの重量と電力要件が大きいため、適切な設置が重要です。

- 電源:三相産業用電力が必要です。

- 冷却:冷却システムには水源または産業用チラーへの接続が必要です。

- サポート:ビデオガイドによる設置と操作トレーニングを提供します。設置と立ち上げのための現場エンジニアリングサポートも利用可能です。