Machine de fusion de mousse EPS pour le recyclage de mousse plastique

| Marque de machine | Machines Shuliy |

| Modèle | SL220, SL880, SL1000 |

| Puissance d'entrée | 3 kW |

| Capacité (kg/h) | 100-250 |

| garantie | 12 mois |

| Matière première | Mousse plastique |

Vous pouvez désormais demander des détails techniques à nos chefs de projets

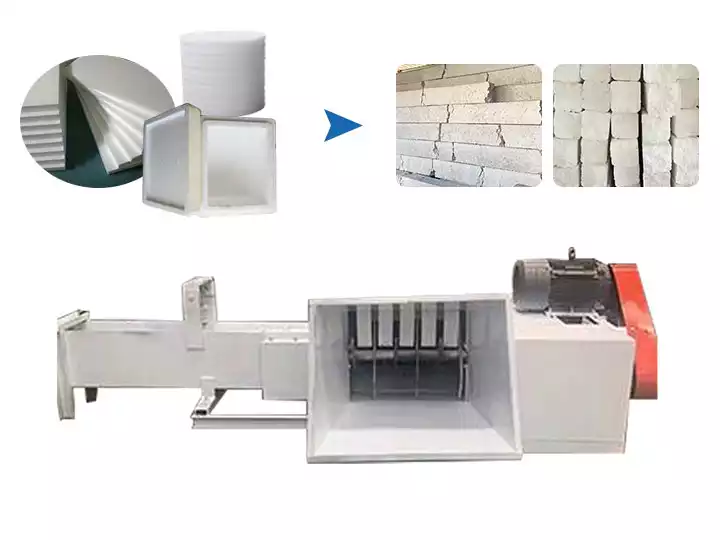

La machine de fusion de mousse Shuliy EPS est également appelée densificateur de mousse de polystyrène. Il est utilisé pour écraser et faire fondre la mousse plastique à haute température. Après concassage et chauffage, la mousse EPS devient des lingots EPS densifiés et un rapport de réduction de volume allant jusqu'à 90 : 1. La machine de densification de mousse peut non seulement réduire le problème de la pollution blanche, mais peut également apporter de grands avantages économiques après le recyclage de la mousse en granulés. C’est donc un équipement nécessaire pour les fabricants de recyclage de plastique. Si vous êtes intéressé, veuillez nous contacter.

Introduction du densificateur de polystyrène à vendre

Les densificateurs de polystyrène à vendre peuvent recycler la mousse de polystyrène (polystyrène/EPS/mousse 6), qui est largement utilisée pour l'isolation et les matériaux de protection des produits pendant le transport. Une fois le concassage terminé, ils seront poussés par la vis vers la zone de chauffage, après chauffage et plastification, la matière première plastique fondra en un tas, facile à transporter et à vendre.

Les matériaux que la machine peut traiter comprennent les boîtes de restauration rapide en mousse, les boîtes d'emballage en mousse, les boîtes à gâteaux, les matériaux isolants, la mousse d'emballage extérieur des appareils électriques et d'autres déchets de mousse blanche.

Principe de fonctionnement de la machine de recyclage par fusion à chaud EPS

La machine de fusion de mousse EPS adopte des lames de concassage à double arbre, qui sont deux arbres de lames parallèles, et elles tournent dans des directions différentes. Chaque arbre de lame comporte 18 lames et est entraîné par une boîte de vitesses pour écraser le matériau, qui est transporté vers le baril à travers un tamis. La mousse est transportée vers le fût chauffé par une vis rotative à grande vitesse. La mousse plastique sera ensuite fondue à haute température et extrudée en tas pour s'écouler.

Avantages du densificateur en polystyrène

- Ce densificateur de polystyrène adopte un chargement manuel, le matériau est rapidement écrasé par les lames à double arbre puis transporté vers le baril hôte à travers le tamis, la machine est très efficace.

- La vis hôte transporte et chauffe le matériau jusqu'à l'état de fusion, puis l'extrude et la lame hydraulique le coupe en morceaux pour faciliter le stockage et le transport.

- Le matériau fondu sortant du densificateur de polystyrène peut être collecté par une auge en acier pour obtenir les blocs, ou coupé par une machine de découpe pour obtenir de petits blocs, ce qui est pratique pour le transport de la mousse plastique.

- L’apparence du densificateur EPS peut être conçue selon les exigences du client.

Paramètres de la machine de fusion à chaud du densificateur EPS

| Modèle | Taille de la machine (mm) | Taille d'entrée (mm) | Puissance de configuration (kw) | Puissance d'entrée (kw) | Capacité (kg/h) |

| SL220 | 1500*800*1450 | 450*600 | 15 | 3 | 100-150 |

| SL880 | 1580*1300*850 | 800*600 | 18.5 | 3 | 150-200 |

| SL1000 | 1900*1580*900 | 1000*700 | 22 | 3 | 200-250 |