Как рассчитать рентабельность инвестиций (ROI) высококачественного гранулятора для пластика

One of the first questions any entrepreneur asks is, “is plastic recycling profitable?” The answer is a definitive yes—if you make the right equipment choices. The profitability of your entire operation hinges on the performance and reliability of your core machinery.

Many buyers focus solely on the initial purchase price, but the true measure of a smart recycling machine investment is its Return on Investment (ROI). This guide will provide a framework for a plastic granulator cost-benefit analysis, showing you how a high-quality machine delivers superior long-term value.

Shifting Perspective: Total Cost of Ownership vs. Purchase Price

A cheaper machine is often the most expensive one you can buy. The total cost of ownership of a plastic granulator includes not just the initial price, but also the costs of maintenance, downtime, and energy consumption over its entire lifespan. A well-engineered, durable plastic granulator may have a higher initial cost, but its lower operational costs lead to a much stronger ROI.

The Key Drivers of Your Plastic Granulator ROI

To understand a machine’s true value, we need to look at the factors that drive profitability.

Revenue Drivers: Uptime and Pellet Quality

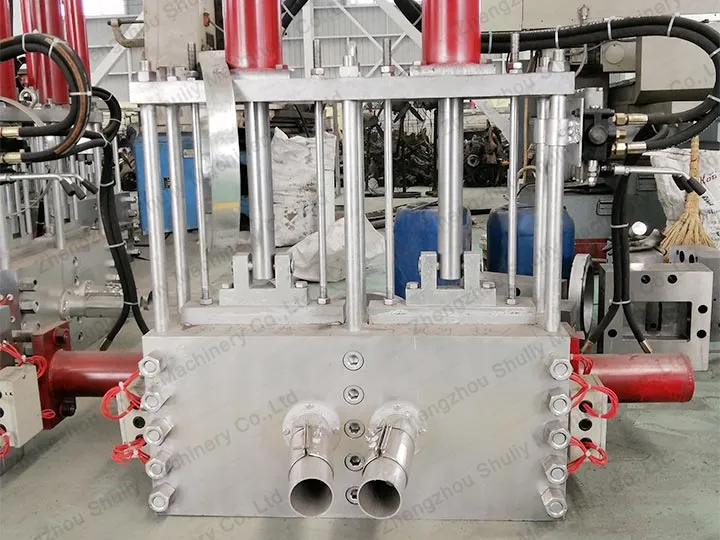

- Granulator Uptime and Profitability are Directly Linked: A machine that is constantly stopped for repairs or manual screen changes is not making money. Features like a non-stop hydraulic screen changer can increase daily production by 20-40%, dramatically shortening the payback period for your recycling machine.

- High-Value Recycled Pellets Command Higher Prices: A machine with superior technology, like a two-stage extruder, produces denser, more uniform pellets that are more valuable to buyers. Better quality output means higher revenue per kilogram.

Cost Reduction Drivers: Durability, Maintenance, and Efficiency

- Durability Reduces Replacement Costs: A machine built with a 38CrMoAl nitrided steel screw and a heavy-duty hard-gear reducer is a low maintenance recycling machine. These components resist wear and tear, saving you thousands in replacement parts and labor over the machine’s life.

- Efficiency Lowers Operational Costs: An energy efficient plastic granulator, for example one equipped with optional electromagnetic heating, can reduce electricity consumption by 30-50% compared to standard systems. This is a direct saving that adds to your bottom line every single day.

A Simple Framework for How to Calculate Recycling ROI

You don’t need a complex financial model to get a clear picture. A basic calculation can guide your decision:

Monthly Gross Profit = (Pellets Sold in kg/month × Price per kg) – (Raw Material Cost + Operational Costs)

Simple ROI = Monthly Gross Profit / Initial Machine Investment

This will give you a percentage return per month. From there, you can easily calculate the payback period: the number of months it will take for the machine to pay for itself. A machine with higher uptime and lower operational costs will always have a faster payback period.

Integrating ROI into Your Plastic Recycling Business Plan

The question “is plastic recycling profitable?” is best answered within your plastic recycling business plan. Your choice of equipment is a core part of that plan. Whether you are setting up a full plastic film recycling line or a more focused rigid plastic recycling line, the specifications of your plastic granulator will define your production capacity and cost structure.

By investing in quality from the start, you build a more resilient and profitable business model. A machine that runs reliably and produces a high-quality product is the foundation of long-term success in this industry.