500 vs. 3000 kg/h: Key Differences in PET Recycling Line Configuration

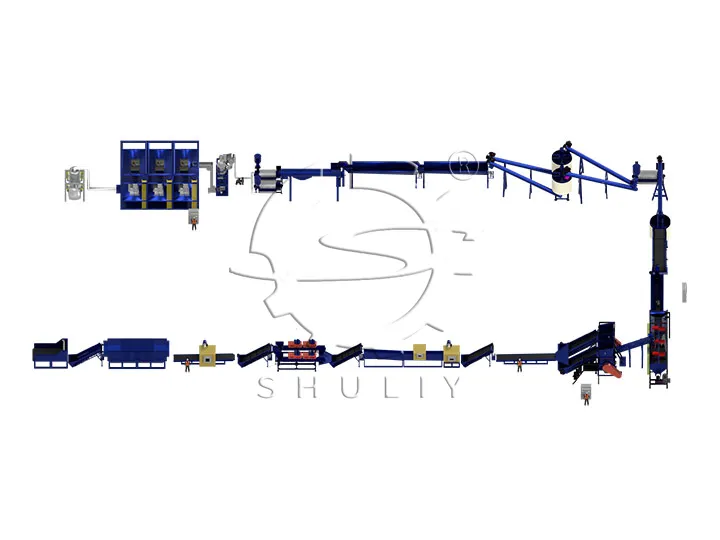

Choosing your PET line capacity is the most fundamental decision you’ll make. A 3000 kg/h high capacity recycling line isn’t just a bigger version of a 500 kg/h small scale PET recycling setup; it’s a completely different philosophy in recycling plant configuration.

Here are the key distinctions:

- Automation Level: The 3000 kg/h line is highly automated, featuring essential machines like a Bale Breaker Und Trommel Screen to handle the massive input volume with minimal labor. The 500 kg/h line often relies on manual feeding and pre-sorting.

- Washing & Rinsing Intensity: A large line will feature hot washer tanks (e.g., two) and more rinsing stages. This ensures every flake gets sufficient residence time for deep cleaning, something a single-tank small line cannot guarantee at high speeds.

- Equipment Robustness: Everything in a 3000 kg/h line is bigger and tougher—thicker steel walls, larger motors (e.g., 90kW crusher vs. 22kW), and more durable components designed for 24/7 operation.

- Purification & Finesse: High-capacity lines almost always include advanced purification steps like a Zig-Zag Air Classifier to remove fine dust and labels, a feature often considered an optional extra on smaller lines.

The Bottom Line: A 500 kg/h PET recycling line is great for entering the market or targeting niche applications. A 3000 kg/h line is an industrial powerhouse built for producing consistently high-quality rPET flakes at the lowest possible cost per ton.