全自動タイヤリサイクルライン

| 加工可能なタイヤサイズ | 1200mm以下 |

| 日産能力 | 3〜35トン/日(24時間) |

| エネルギー消費 | ≤ 40 kWh/トン |

| ゴム粉末サイズ | 10〜80メッシュ |

| 粉末純度 | 99.2%以上 |

技術的な詳細についてプロジェクト マネージャーに問い合わせることができるようになりました

毎年、数十億のスクラップタイヤが「黒い汚染」という厄介な課題を生み出し、私たちの地球に負担をかけています。しかし、この課題の中には、利益を生む「黒い金」の機会が潜んでいます。Shuliyでは、この環境問題をあなたの利益のある事業に変えることに特化したタイヤリサイクル機械の製造業者です。

当社の高度な全自動タイヤリサイクルラインは、廃タイヤを効率的かつ確実に高価値商品(微細ゴム粉末、ゴム粒、高純度スチールワイヤー)に変換し、資源の完全な利用を保証します。最も重要なことは、当社の独自の省エネ技術により、運用電力消費量を最大33%削減でき、収益性と競争力を根本的に強化することです。

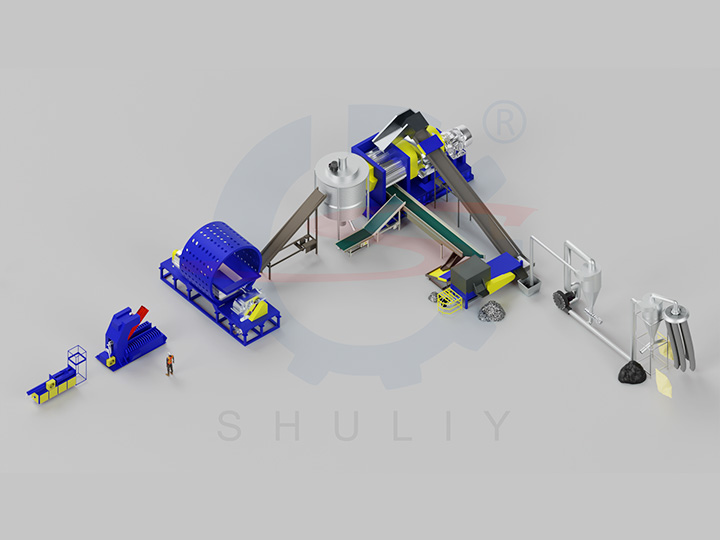

Shuliyゴム粒子生産ラインの仕組み

複雑なタイヤリサイクルプロセスを、シームレスで高度に自動化されたワークフローに合理化しました。最小限の労力で、廃タイヤは効率的に市場性のある商品に変換されます。

ステップ1:廃タイヤの前処理 – 効率的なスチールビード除去

廃タイヤは前処理ユニットに投入されます。お客様のニーズに応じて、デビダー(ワイヤー引き抜き機)が太いビードワイヤーを抽出するか、タイヤリングカッターがサイドウォールを分離し、その後スチールワイヤーセパレーターが続きます。このステップで、高価値でクリーンなスチールビードリングが得られます。

ステップ2:一次破砕 – 強力なサイズ削減

前処理されたタイヤはタイヤシュレッダーに搬送されます。強力なデュアルシャフトブレードシステムにより、タイヤ全体を均一な50〜100mmのゴムブロックに容易に引き裂き、微粉砕ステージの準備をします。

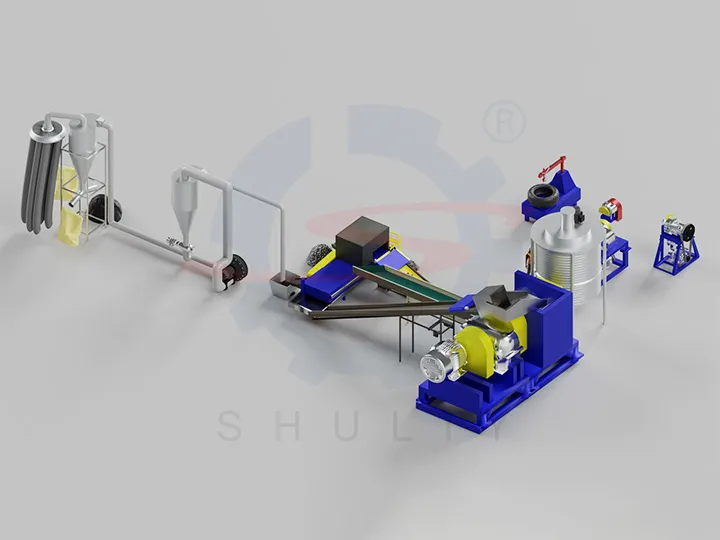

ステップ3:微粉砕 – ゴム粉末への製粉

ゴムブロックは、ラインのコア部分、つまりゴムミル(廃タイヤ破砕機とも呼ばれる)に入ります。合金ローラーの強力な圧力とせん断作用により、ゴムブロックは 5-40 メッシュの細かいゴム粉末に急速に粉砕されます。最終的なメッシュサイズは、市場の需要に合わせて調整可能です。

ステップ4:分離と精製 – 純粋な最終製品の達成

タイヤゴム破砕プロセス全体を通じて、統合された磁気分離器と繊維(ナイロン)空気分類器が材料を精製するために機能します。磁気システムは細かい鋼線を引き出し、空気分類器はナイロンやその他の繊維質材料を除去します。その結果、高品質のゴム粉末、細かい鋼線、ナイロン繊維という 3 つのクリーンで販売可能な最終製品が得られます。

最終ゴム粉末/ゴム粒および副産物

当社のコア技術とコンポーネント

優れた性能は、細部への絶え間ないこだわりから生まれます。ゴム粒生産ラインの最も重要な2つの装置を検証します。

ゴムミル:ラインの心臓部、効率の源

ゴムミル(ゴム破砕機)は、最終製品の品質と全体的な生産性を決定します。当社の設計は、主要なすべての領域において従来の装置を凌駕しています。

- コアローラー:5Cr6MnMo耐摩耗合金製で、デュアルグルーブ設計。利点:卓越した耐久性(3年保証付き)と、1:2.5の速度比による優れたせん断力により、生産性が向上します。

- 軸受システム:当社の廃タイヤ破砕機には、8 列のダブルローラーベアリングが装備されています。利点:これにより、操作上の摩擦と熱が大幅に削減され、最大 33% のエネルギー削減と機械寿命の延長につながります。

- 減速機(ギアボックス):当社の廃タイヤ破砕機は、デュアルギア列設計のハイポイドギア減速機を採用しています。利点:低ノイズで信頼性が高く、長持ちするパフォーマンスを確保しながら、より高いトルクと負荷容量を提供します。

タイヤシュレッダー:あらゆる廃タイヤに対応するパワフルな性能

タイヤシュレッダーは、全自動タイヤリサイクルラインのもう一つの主要な機械であり、その性能は極めて重要です。当社のシュレッダーは、パワーと耐久性のために作られています。

- シュレッダーブレード:特殊熱処理された複合合金鋼製。利点:硬度と靭性の完璧なバランスを提供し、ブレードはメンテナンスが必要になるまで長期間、スチールベルトタイヤを引き裂くことができます。ブレードの厚さは、大型モデルでは最大100mmに達します。

- パワフルなモデルレンジ:900モデルから1800モデルまでのフルレンジを提供。利点:64.5 kWから巨大な328.5 kWの出力定格と、毎時2トンから20トン以上の処理能力により、お客様の運用規模と野心に合わせた適切な機械を提供します。

お客様の成功のために設計されたスマートな投資

タイヤリサイクルへの投資は、高成長で持続可能な産業への投資です。当社の全自動タイヤリサイクルラインは、このベンチャーにおける最も信頼できるパートナーであり、優れた投資収益率、コア省エネ技術による低運用コスト、堅牢な設計に裏打ちされた長期的で信頼性の高い生産を提供するように設計されています。

「黒い汚染」をあなたの「黒い金」に変える時です。今日、Shuliyの技術専門家に連絡して、無料のカスタマイズ提案と詳細なROI分析を受け取りましょう!