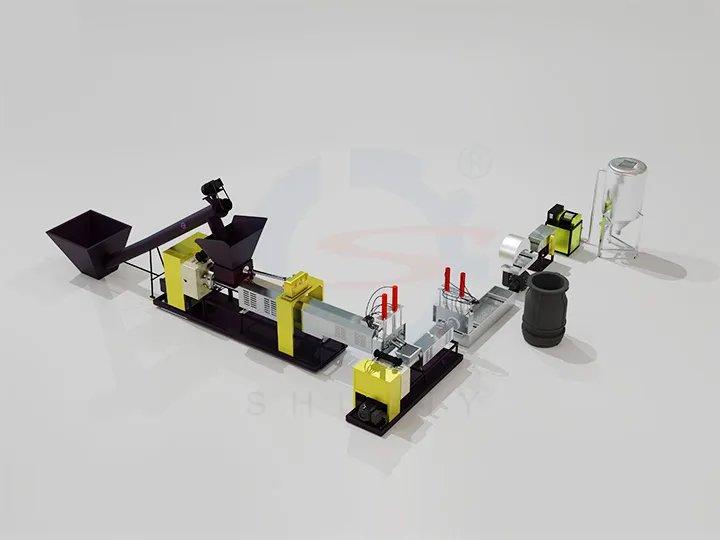

LDPE滴灌带造粒设备

低密度聚乙烯滴灌带的回收利用

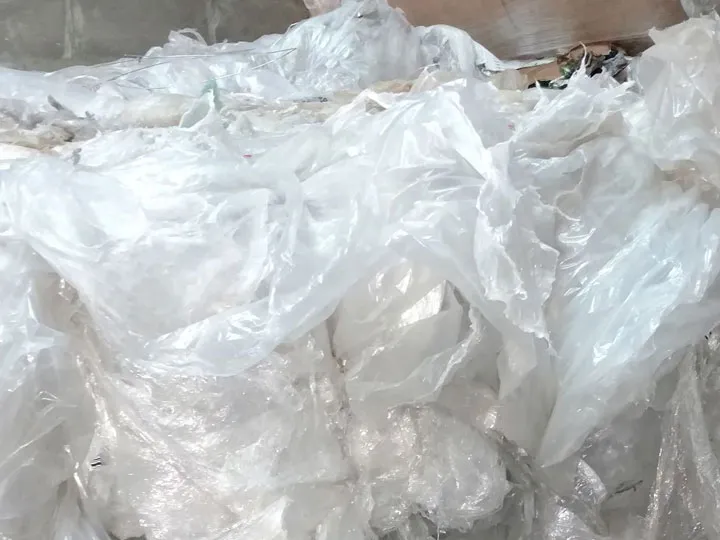

LDPE(低密度聚乙烯)滴灌带是农业灌溉中常用的塑料制品,由于其柔韧性和耐用性而得到广泛应用。然而,它们往往在使用寿命结束时被大量丢弃,造成环境影响。回收废弃的滴灌带将其转化为具有经济价值的聚丙烯颗粒。

LDPE滴灌带造粒工艺

以下是回收LDPE滴灌带的主要步骤和方法。

步骤 1: 撕碎成小块

废弃的 LDPE 滴灌带通过专门的塑料粉碎机进行加工,将其切割或撕成小块或条状。此步骤的目的是减小材料的尺寸,以便后续清洁和处置。

- 推荐装备: 塑料撕碎机,适合加工软塑料和农业废弃物。

步骤 2: 清洗 LDPE 片

滴灌带破碎后的碎片进入塑料洗涤池,通过搅拌或喷淋去除土壤、灰尘、化学残留物和其他杂质。

步骤 3: 提升材料并去除水分

清洗后的塑料件在干燥设备中脱水,确保其干燥,以供后续加工使用。

- 常用设备: 塑料升降干燥机

步骤 4: LDPE 滴灌带造粒

干燥后的LDPE切片经塑料造粒机熔融、挤出造粒,最终制成高质量的塑料颗粒。

- 推荐回收设备: 塑料造粒机

概括

通过破碎、清洗、干燥、造粒的全过程,废弃LDPE滴灌带可重复利用。生产的LDPE颗粒可用于再制造滴灌带、塑料薄膜、管道等。不仅减少塑料垃圾对环境的危害,还为塑料回收行业提供新的商机。